Silica gel bulk material with hydrophilic, slip surface and tapered copper needle with superhydrophobic-hydrophilic surface for water mist collection

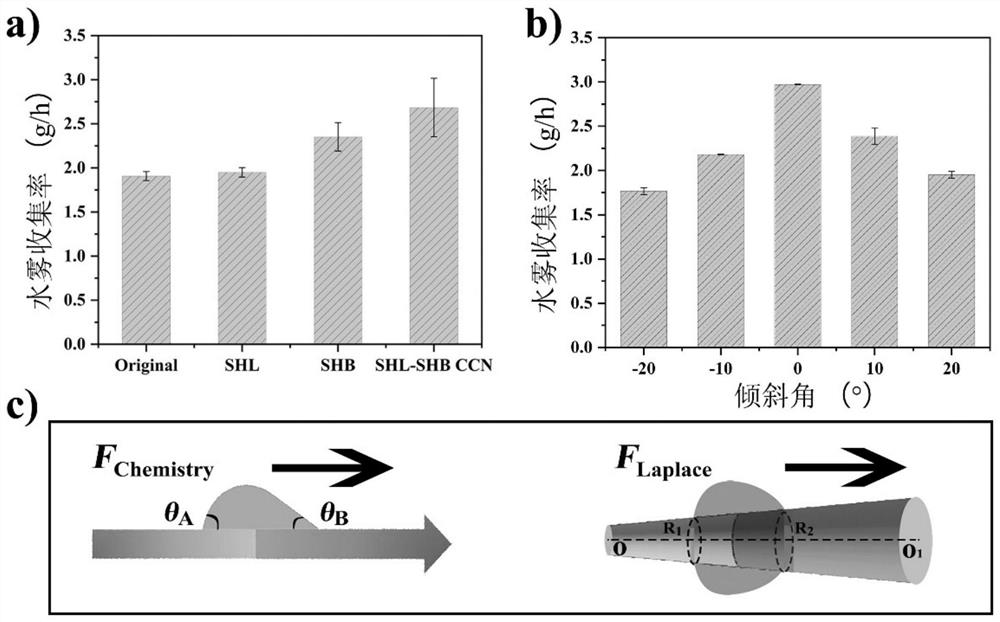

A technology of hydrophilic surface and silica gel block, which is applied in the field of materials, can solve the problems of low practicability, fluorine-containing preparation materials, and complicated preparation steps, etc., and achieve the effects of reducing energy consumption, high collection efficiency, and promoting directional transportation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

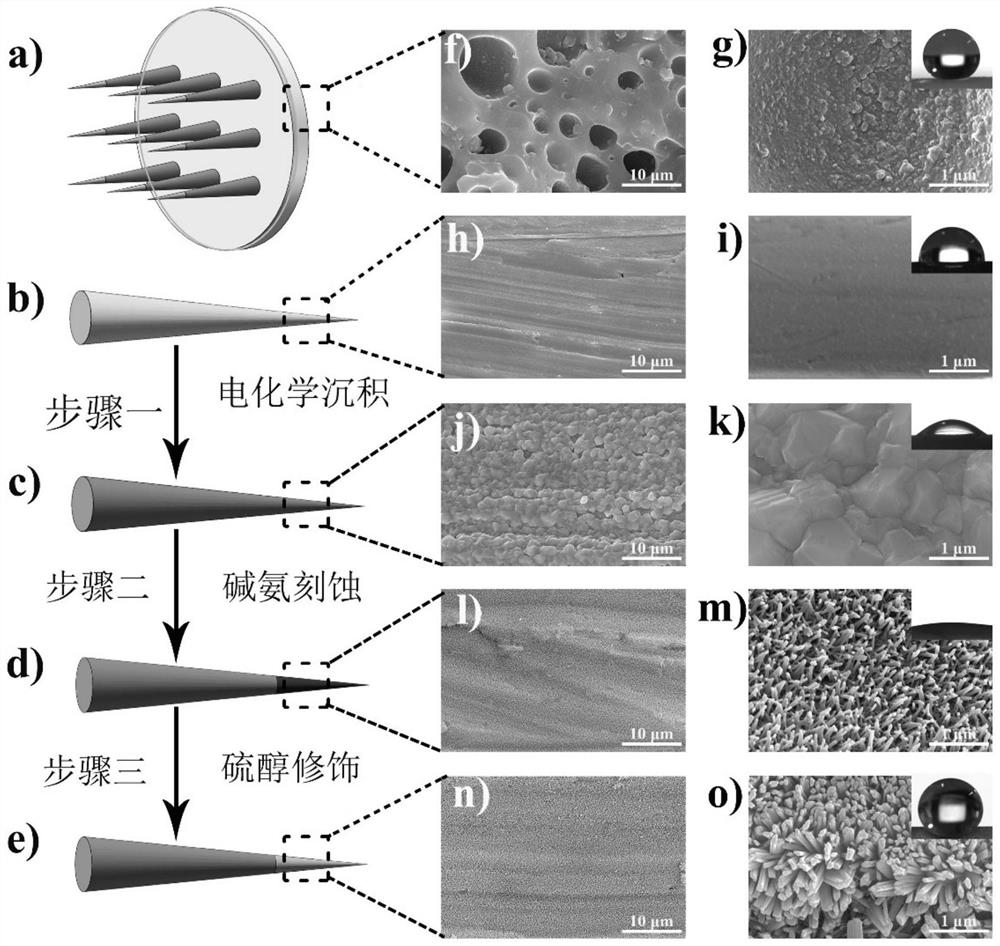

[0029] 1. Preparation of copper surface with nano-block structure by electrodeposition method: first, select a copper needle with a length of 3 cm. In order to remove the pollutants on the surface of the copper needle, ultrasonically clean it with ethanol and deionized water for 5 minutes, and then use 0.1M hydrochloric acid solution to remove the oxide layer. The treated copper needles were electrodeposited by an electrochemical workstation, wherein the copper needles were used as the cathode, the platinum electrode was used as the anode, and the saturated calomel electrode was used as the auxiliary electrode, and the selected electrolyte was 0.5M copper sulfate solution. Deposition was performed for 600 s under the time-current window. The copper needle was taken out, washed with ethanol and dried under nitrogen flow for 3 min.

[0030] 2. Preparation of copper hydroxide nanowires at the tip of the electrodeposited copper needle: First, use sandpaper to polish the 1 cm long...

Embodiment 2

[0035] 1. Preparation of copper surface with nano-block structure by electrodeposition method: first, select a copper needle with a length of 3 cm. In order to remove the pollutants on the surface of the copper needle, ultrasonically clean it with ethanol and deionized water for 5 minutes, and then use 0.1M hydrochloric acid solution to remove the oxide layer. The treated copper needles were electrodeposited by an electrochemical workstation, wherein the copper needles were used as the cathode, the platinum electrode was used as the anode, and the saturated calomel electrode was used as the auxiliary electrode, and the selected electrolyte was 0.5M copper sulfate solution. Deposition was performed for 600 s under the time-current window. The copper needle was taken out, washed with ethanol and dried under nitrogen flow for 3 min.

[0036] 2. Preparation of copper hydroxide nanowires at the tip of the electrodeposited copper needle: First, use sandpaper to polish the 1 cm long...

Embodiment 3

[0041] 1. Preparation of copper surface with nano-block structure by electrodeposition method: first, select a copper needle with a length of 3 cm. In order to remove the pollutants on the surface of the copper needle, ultrasonically clean it with ethanol and deionized water for 5 minutes, and then use 0.1M hydrochloric acid solution to remove the oxide layer. The treated copper needles were electrodeposited by an electrochemical workstation, wherein the copper needles were used as the cathode, the platinum electrode was used as the anode, and the saturated calomel electrode was used as the auxiliary electrode, and the selected electrolyte was 0.5M copper sulfate solution. Deposition was performed for 600 s under the time-current window. The copper needle was taken out, washed with ethanol and dried under nitrogen flow for 3 min.

[0042] 2. Preparation of copper hydroxide nanowires at the tip of the electrodeposited copper needle: First, use sandpaper to polish the 1 cm long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com