A measurement system for thermal field distribution of sonic nozzle pipe wall

A sonic nozzle and measurement system technology, applied in the direction of measuring heat, measuring devices, thermometers using electric/magnetic elements that are directly sensitive to heat, etc., can solve the problem of large environmental changes in the temperature measurement system, insufficient temperature measurement steps, and Problems such as limited temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the features, operation process, specific advantages and performances of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

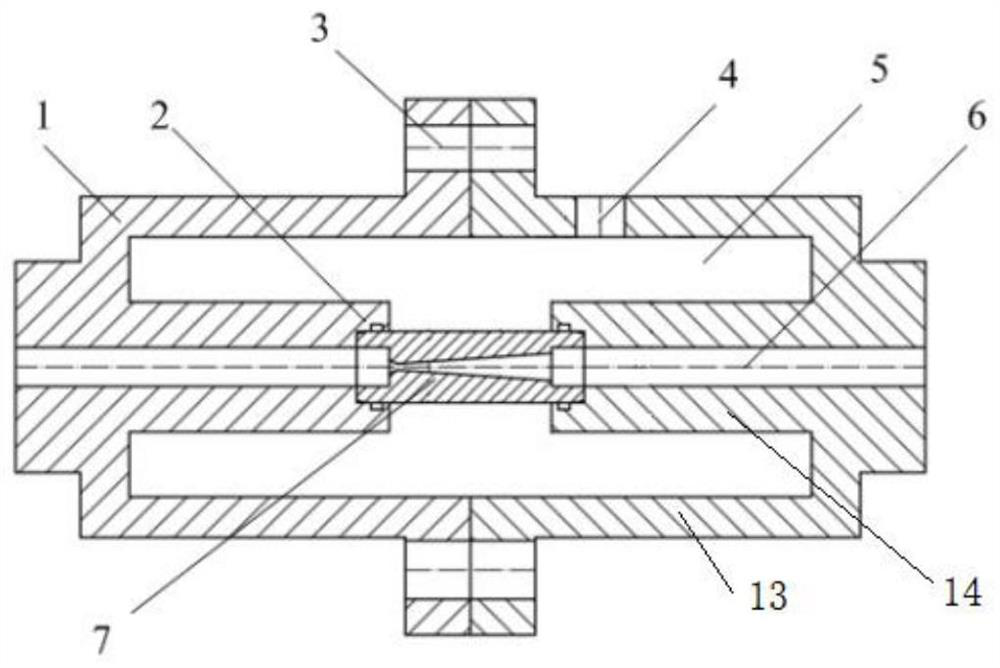

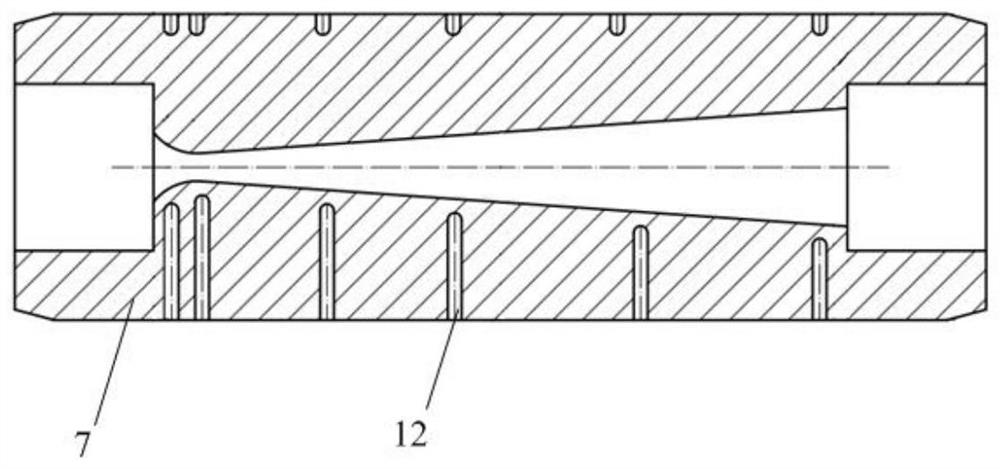

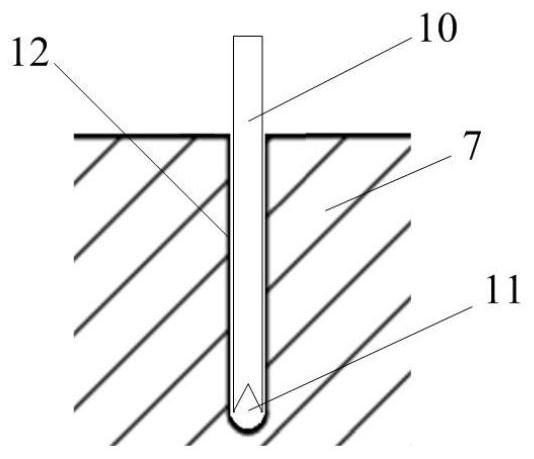

[0024] see figure 1 , the stable installation of the sonic nozzle 7 is a precondition for measuring the temperature field of the pipe wall, so in the present invention, a design such as figure 1 The shown nozzle heat insulation fixture 1 is used to assist in fixing the sonic nozzle, and can also help the nozzle 7 to better connect with the fluid channel 6 . The main material of the heat insulation fixture 1 is PVC material, which has heat insulation effect. The fixture device is divided into two symmetrical parts, which can be assembled or disassembled through the nuts on the flange plate 3, so that the nozzle 7 can be replaced or the heat insulation fixture can be removed. 1 has become more convenient. O-shaped rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com