Method for improving measurement accuracy of uneven sample elements based on LIBS

A technology of unevenness and accuracy, which is applied in the field of improving the measurement accuracy of uneven samples based on LIBS, and can solve the problems that the samples cannot be subjected to complex pretreatment, the effect of uneven samples is not ideal, and the sample pretreatment is not applicable. Simple preprocessing, high accuracy, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

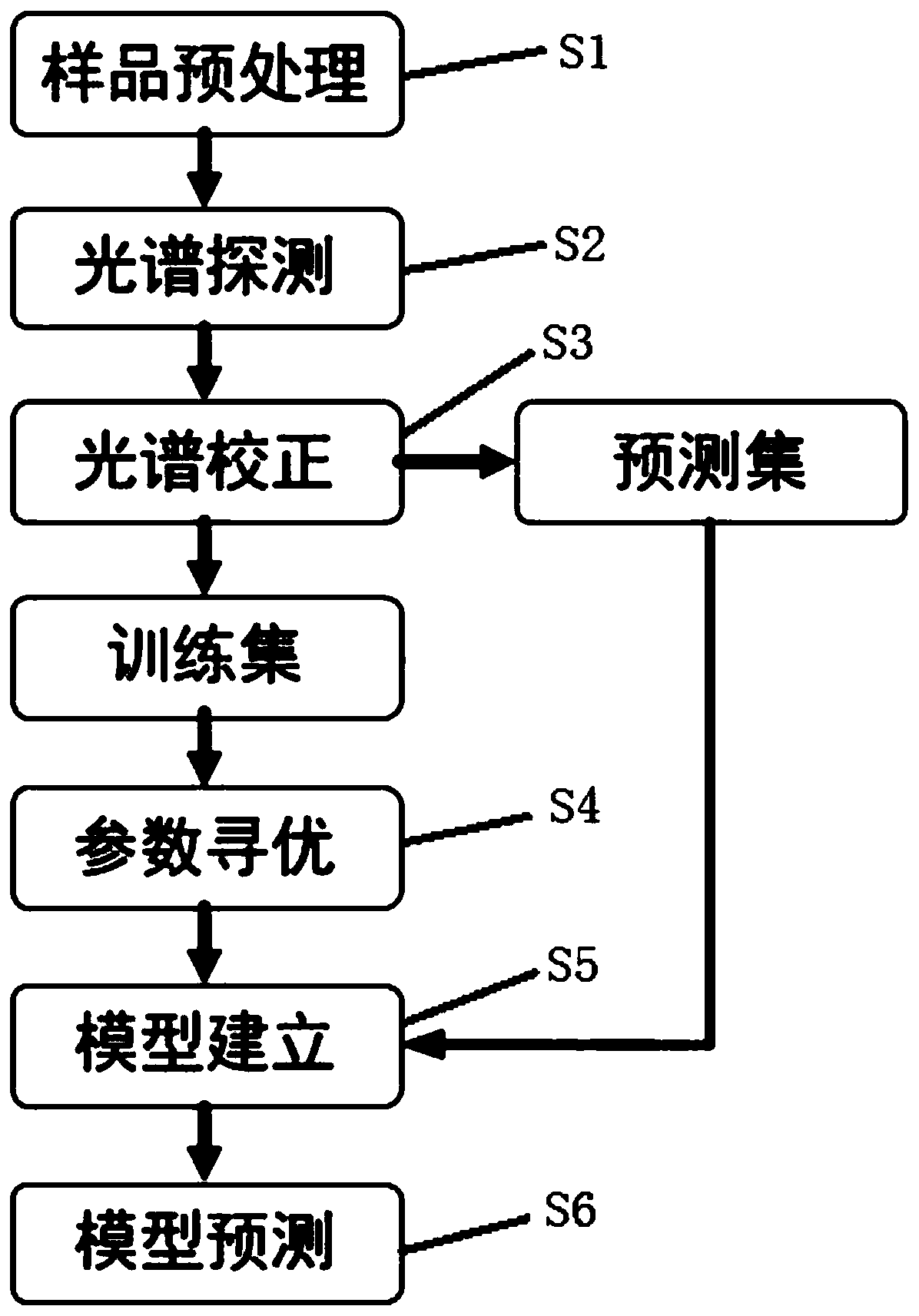

[0032] like figure 1 As shown, in some optional embodiments, the method for improving the measurement accuracy of uneven sample elements based on LIBS of the present invention includes the following steps:

[0033] S1. Sample pretreatment: Use the original uneven surface sample or the sample after pretreatment such as grinding, adding adhesives, fixing, etc. as the detection object;

[0034] S2. Spectral detection: use LIBS technology to collect spectral data of the sample described in S1;

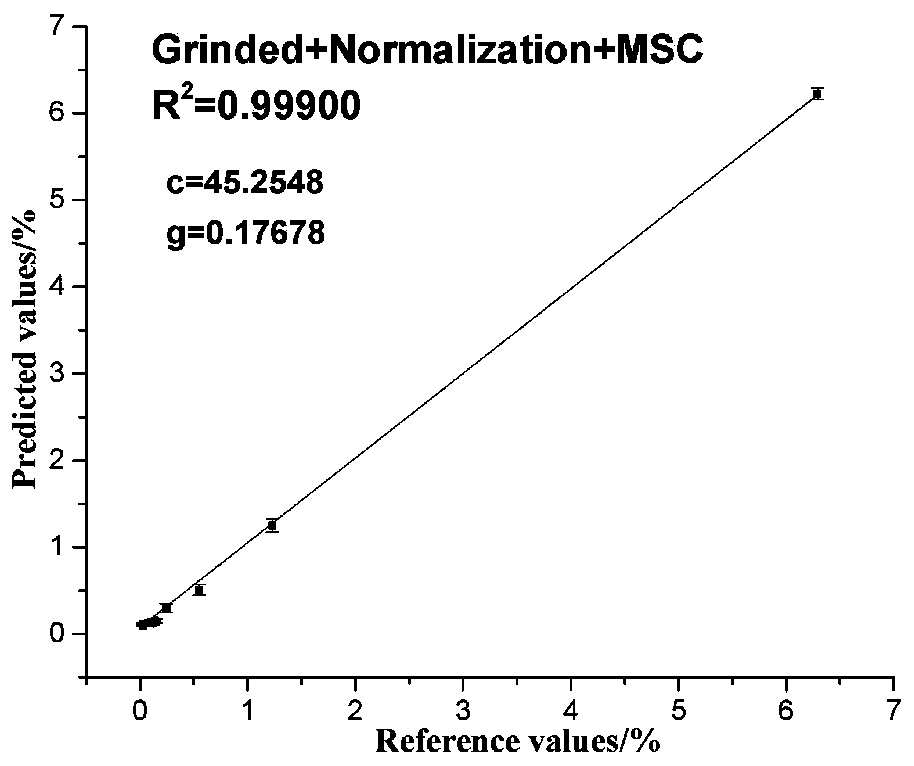

[0035] S3. Spectral correction: Considering the sample and spectral characteristics, select the intensity normalization method with the idea of internal standard in a targeted manner, and combine it with the multivariate scattering correction method that can correct the scattering effect, and pre-process the original spectral data obtained in S2. processing, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com