Film coating and rubberizing equipment for semiconductor chip

A semiconductor and adhesive technology, applied in the field of coating and adhesive equipment for semiconductor chips, can solve the problems of crooked adhesive, poor adhesive quality, low efficiency, etc., to achieve high yield, reduce the demand for human resources, and improve the overall effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

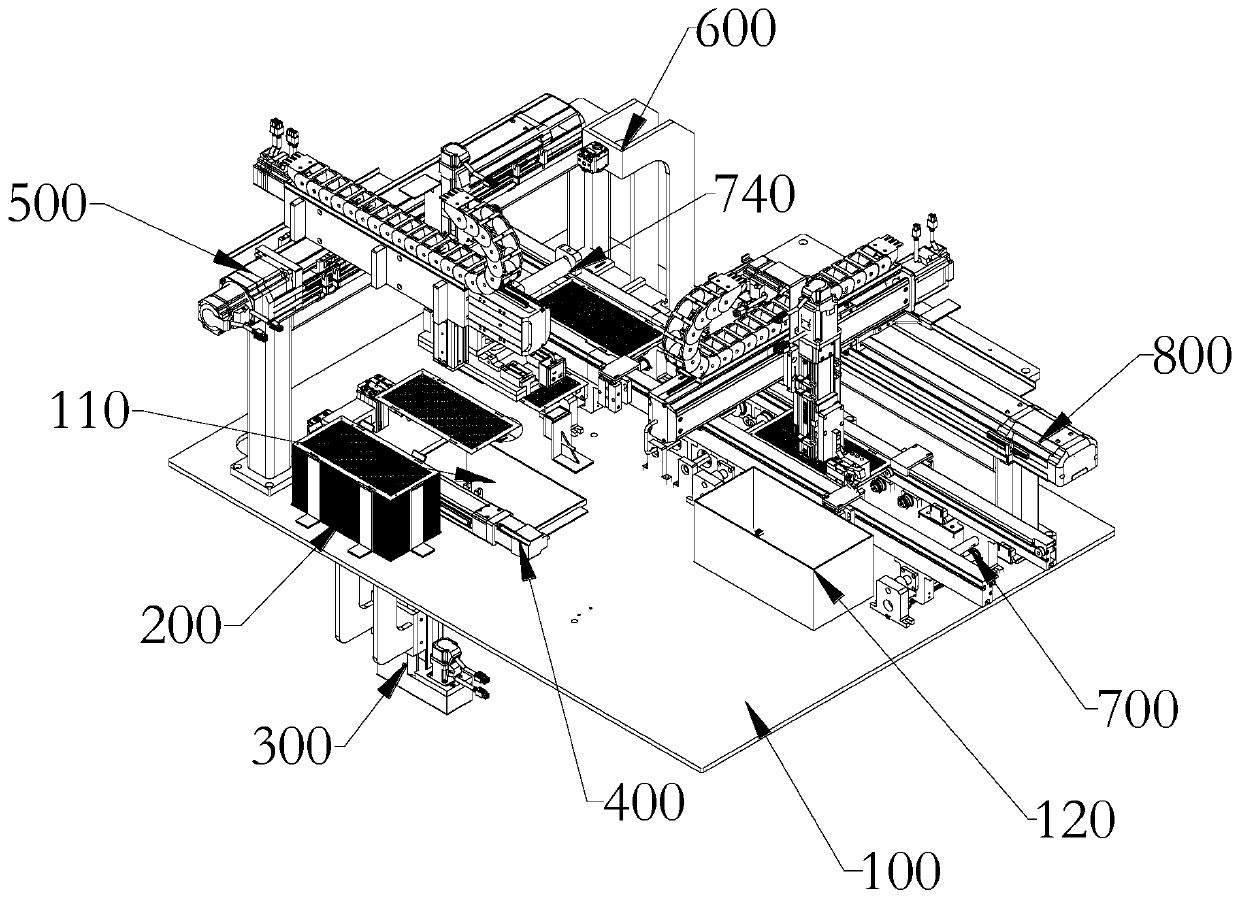

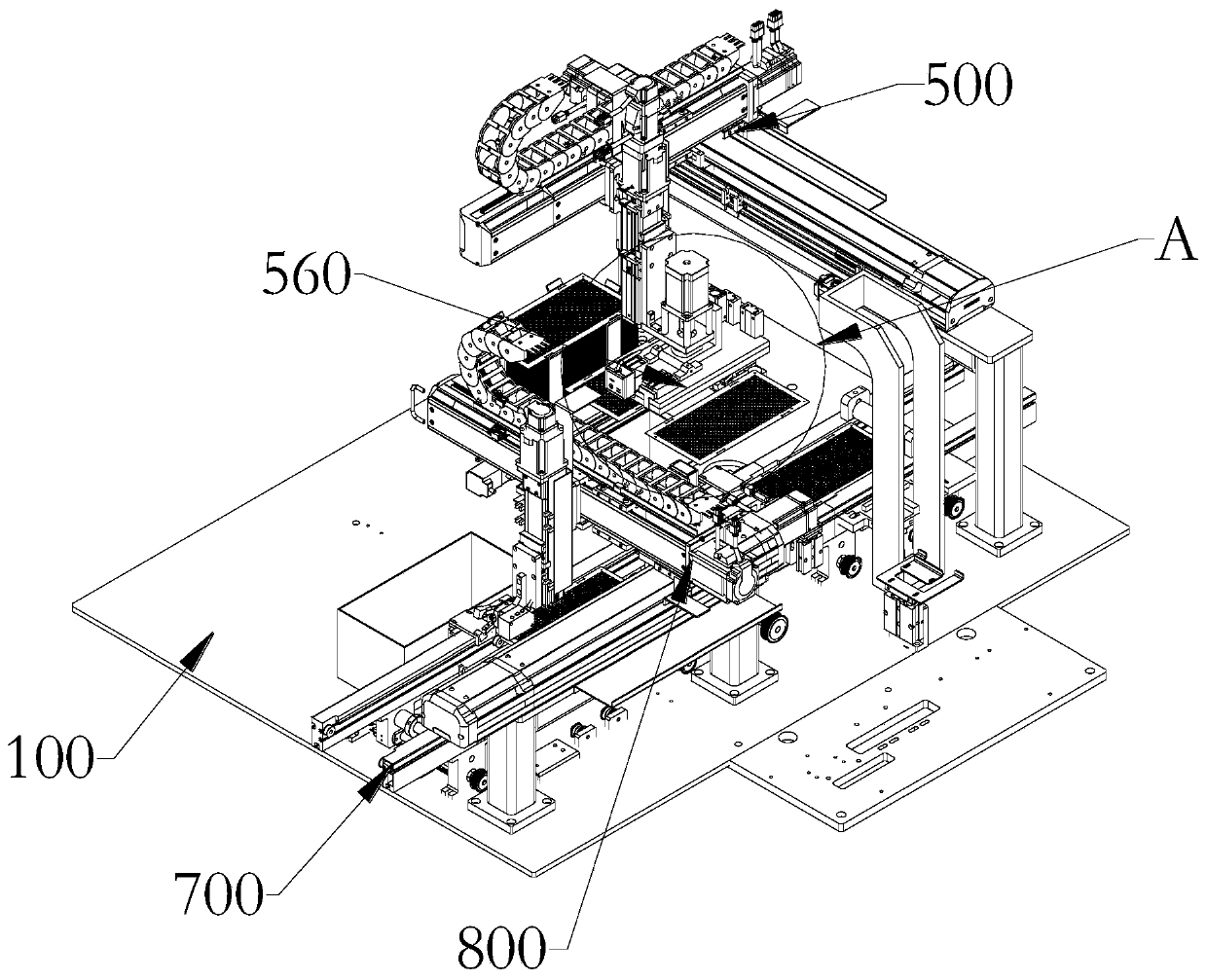

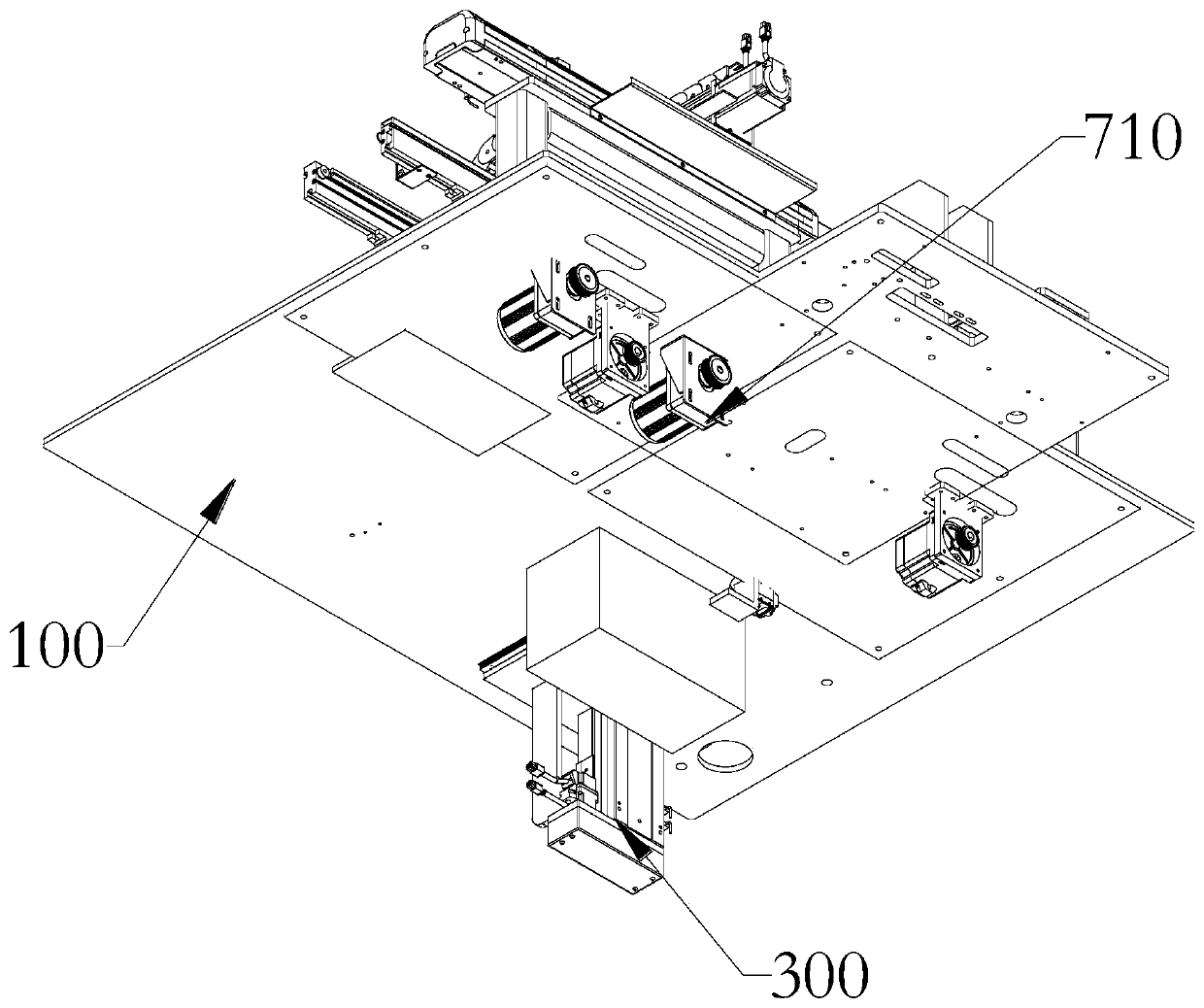

[0029] Reference Figure 1-Figure 3 , A coating and glueing equipment for semiconductor chips, including a machine 100. The machine 100 is sequentially provided with a loading bin 200, a loading device 500, a bottom film tearing device 400, a glue transfer device 700, and a film tearing device 800 ;

[0030] After the loading device 500 takes out the blue glue from the loading bin 200, it tears off the bottom film of the blue glue through the bottom film tearing device 400, and then pastes the blue glue from the bottom film on the coating film placed on the glue transfer device 700 On the jig, the coating jig is transferred to the film tearing device 800 through the pressure glue transfer device 700, after the film is removed, and then transferred out of the equipment.

[0031] Furthermore, refer to figure 1 A bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com