Permanent magnet motor capable of rapid cooling

A permanent magnet motor, fast technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of poor cooling effect, achieve good cooling effect, fast flow rate, increase heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

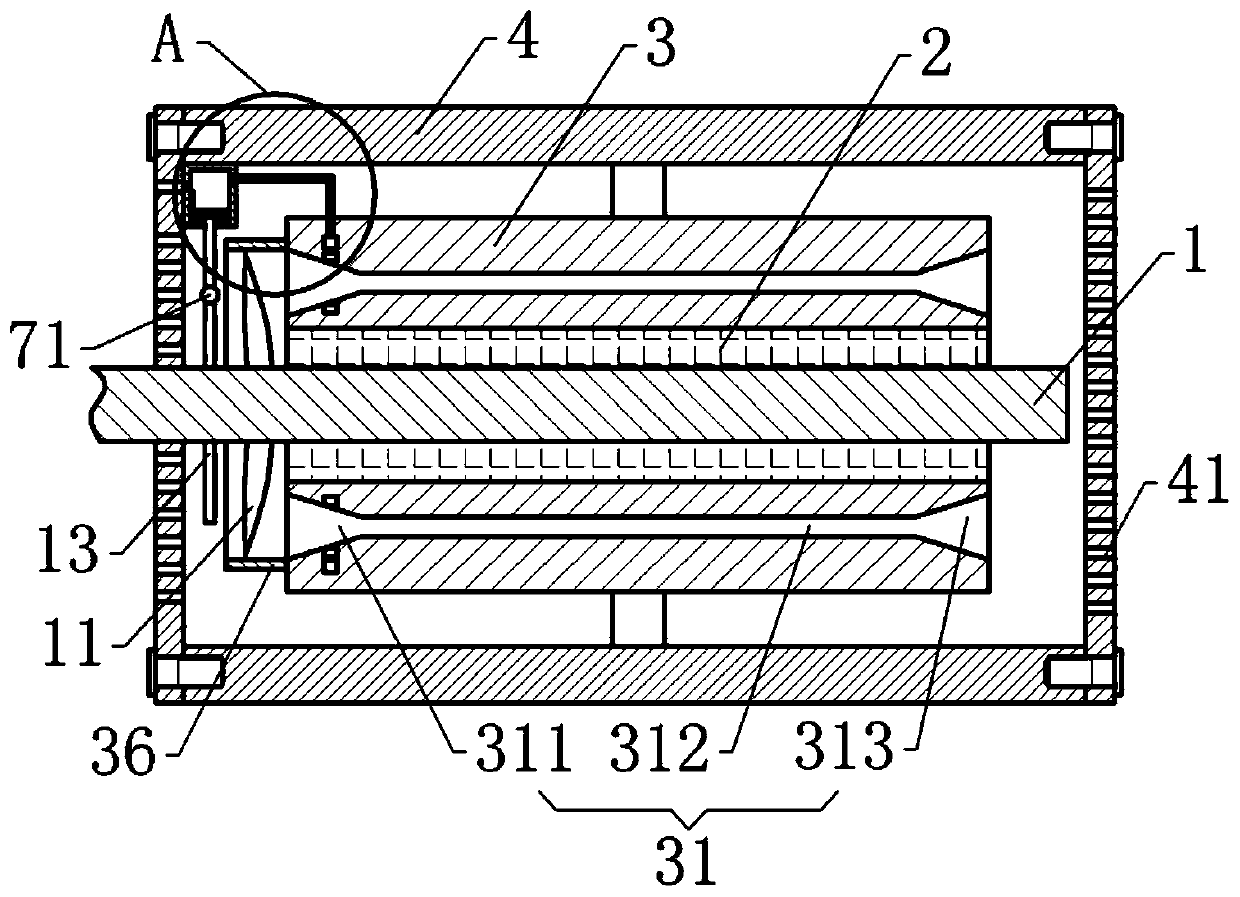

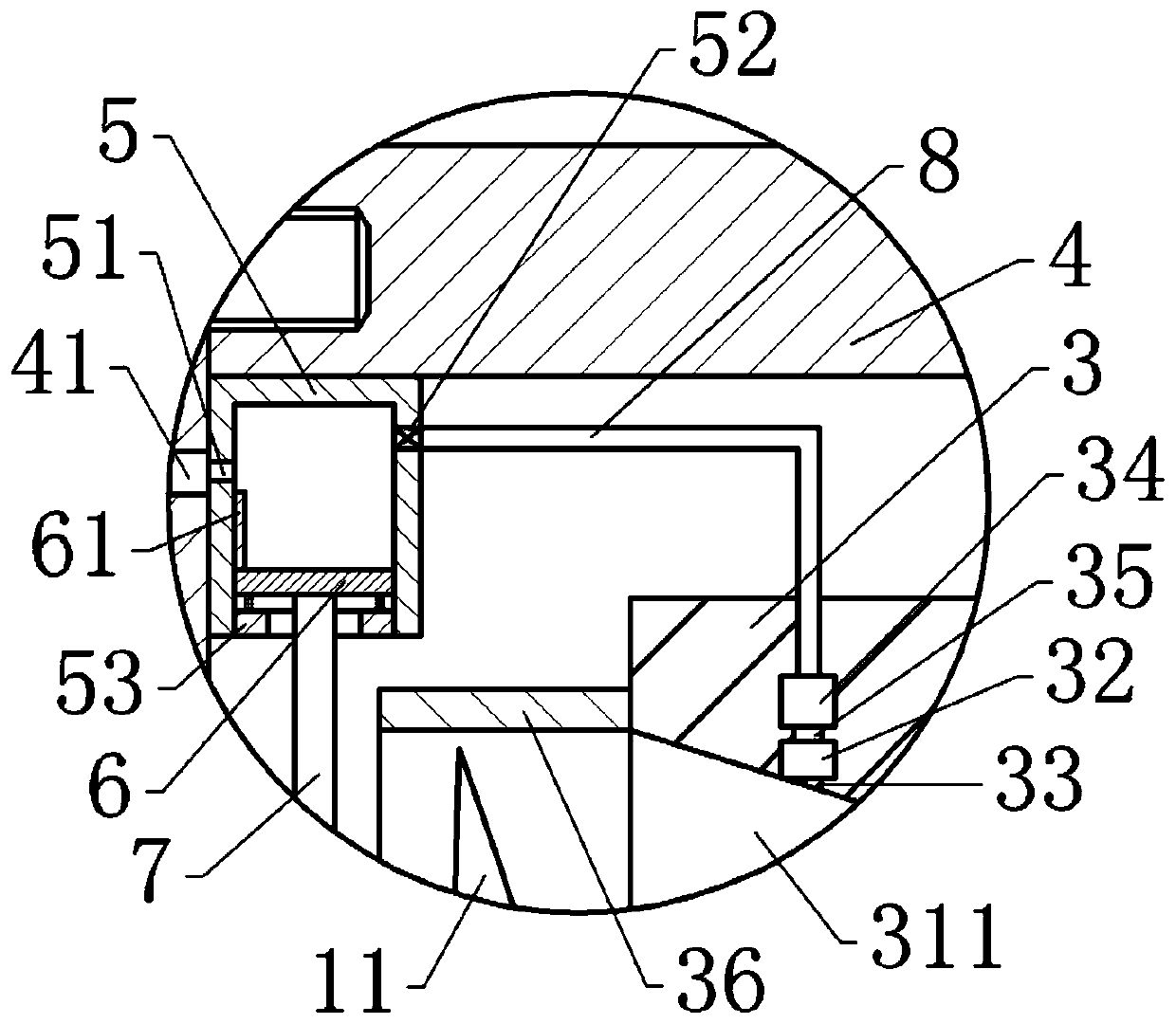

[0038] A permanent magnet motor with rapid cooling, basically as attached figure 1 As shown, it includes a drive shaft 1, a rotor 2, a stator 3, and a casing 4 arranged in sequence from the inside to the outside. The rotor 2 is a permanent magnet, and a fixed block is welded on the outside of the stator 3. The side of the fixed block away from the stator 3 is welded to the casing. 4 inside. The casing 4 includes a casing wrapped around the stator 1 and end caps installed on both sides of the casing. The end caps are provided with a plurality of air holes 41, and the end caps are fixed on the casing by bolts. by figure 1 The view of , the left side of the shell 4 is the front end, and the right side of the shell 4 is the rear end.

[0039] The front end of the drive shaft 1 passes through the front end cover, and the front end of the drive shaft 1 extends out of the end cover, and the drive shaft 1 is rotatably connected to the front end cover. The front end of the drive sha...

Embodiment 2

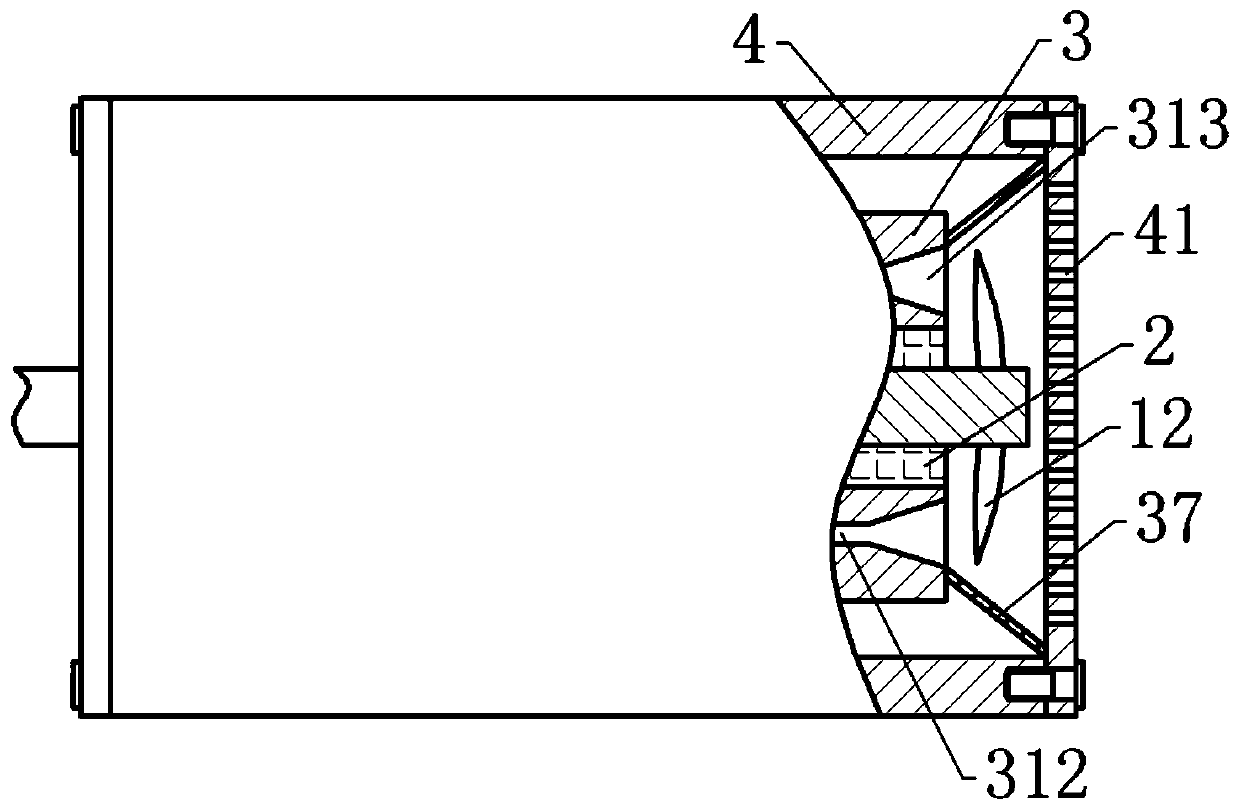

[0052] Embodiment 2 differs from Embodiment 1 only in that, as image 3 As shown, the rear end of the stator 3 is welded with a second windshield 37, and the second windshield 37 wraps four air guide passages 31; the second windshield 37 is conical, and the second windshield 37 is large The diameter end faces right, and the right end of the second windshield 37 abuts against the end cover on the right side. Three second rotating blades 12 are welded on the rear end of the drive shaft 1, and the three second rotating blades 12 form the structure of fan blades, so that when the second rotating blades 12 rotate, the gas on the front side is sucked in and discharged to the rear side .

[0053] During the operation of the motor, the drive shaft 1 drives the second rotating blade 12 to rotate, so that the rotation of the second rotating blade 12 generates a flow of gas, which quickly sucks the gas in the air guide channel 31 and discharges it to the right. During this process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com