Honeycomb-shaped laminar flow-plug flow type photocatalytic reactor

A photocatalytic reactor and photocatalytic reaction technology, which are applied in chemical instruments and methods, dispersed particle separation, separation methods, etc. The diameter of the device should not be too large to achieve the effect of facilitating the overall coating, realizing the functions of diversion and air distribution, and reducing the amount of catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

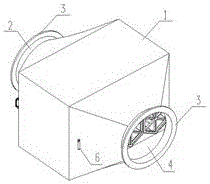

[0036] attached Figure 1-4 The first embodiment of the honeycomb photocatalytic reactor is given. The honeycomb photocatalytic reactor in this embodiment is composed of a rectangular box, an inspection door, a reaction substrate, a lamp tube and its accessories.

[0037] The box body 1 is used to house the honeycomb-shaped photocatalytic reaction module 8. Inside the box body 1, a plurality of baffles 7 are arranged. pass. The exhaust gas enters the box 1 from the air inlet 2, and after being filtered by the primary filter device (such as non-woven fabric) at the air inlet 2, it enters the honeycomb photocatalytic reaction module 8, and is discharged from the exhaust port 4 after purification. The flanges 3 on the air inlet 2 and the exhaust port 4 are used as reserved interfaces for connecting with the pipelines of the exhaust gas collection system and the exhaust gas discharge system respectively.

[0038] The inlet and outlet ends of the above-mentioned reactor are prov...

Embodiment 2

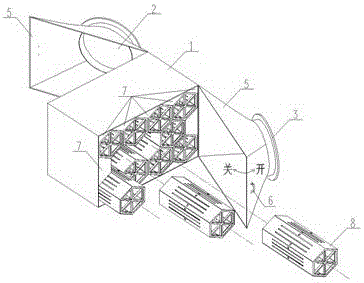

[0042] attached Figure 5 The second embodiment of the honeycomb photocatalytic reactor is given. The honeycomb photocatalytic reactor in this embodiment is composed of a rectangular box, an inspection door, a reaction substrate, a lamp tube and its accessories.

[0043] In this embodiment, the only access door 5 is located on the top of the box body 1, the maximum opening and closing angle of the access door 5 is 180°, and a bead is provided at the connection between the access door 5 and the box body 1 to ensure airtightness. In order to facilitate direct hoisting from the top, the honeycomb photocatalytic reaction modules 8 are connected by welding in this example.

[0044] Other components and their connections are the same as in Embodiment 1.

Embodiment 3

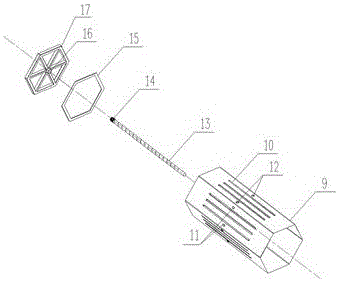

[0046] attached Image 6 The third embodiment of the honeycomb photocatalytic reactor is given. The honeycomb photocatalytic reactor in this embodiment is composed of a box body, an inspection door, a reaction substrate, a lamp tube and its accessories.

[0047] In this embodiment, the box body 1 is a circular tubular structure, and its diameter is the same as that of the air duct for collecting the gas to be treated, and flanges 3 are provided on both the air inlet 2 and the exhaust port 4 . The installation method is to install the reactor directly into the collection pipeline as a piece of air pipe, and connect it to the air pipe through the flange 3 of the air inlet and outlet.

[0048] In this example, only one honeycomb-shaped photocatalytic reaction module 8 is placed in the box, and a plurality of reaction modules can also be arranged, and each reaction module is connected by welding.

[0049] When overhauling, the entire reactor can be overhauled after it is removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com