High-temperature multi-atmosphere microwave energy grinding equipment and method thereof

A multi-atmosphere, microwave energy technology, used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., to achieve the effect of great innovation and practicability, strong electromagnetic interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

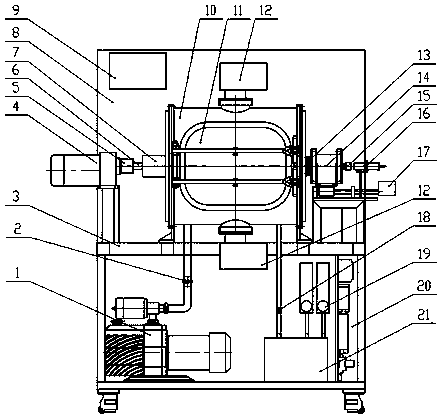

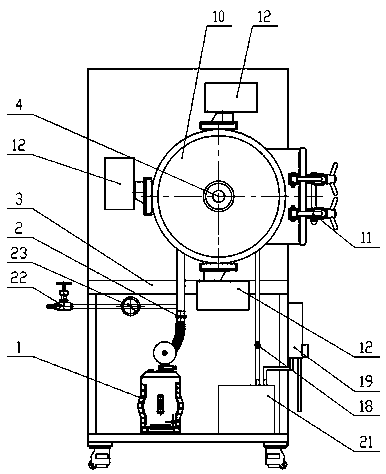

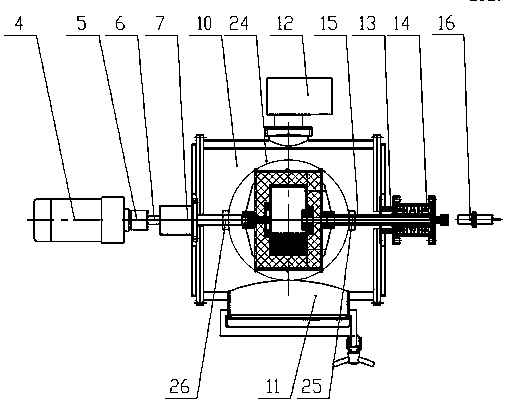

[0041] figure 1 , 2 , 3 show that the high-temperature multi-atmosphere microwave energy grinding equipment of the present invention consists of a multi-mode microwave resonant chamber 10, a microwave source 12, a microwave heating rotary grinding device 24, a power mechanism, a clamping mechanism, a vacuuming mechanism, a ventilation mechanism, and a furnace door 11. The frame 3 and the housing 8 are composed.

[0042] The frame 3 is fixed on the lower part of the multi-mode microwave resonance chamber 10, and the frame 3 is equipped with a ventilation mechanism, a vacuum pumping mechanism and a power distribution control box 20. The multi-mode microwave resonance chamber 10 is a circular double-layer vacuum structure. Microwave sources 12 are respectively provided on, below and behind the outer wall of the multi-mode microwave resonant chamber 10, and the power mechanism and the clamping mechanism are respectively installed on the left and right sides of the multi-mode micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com