Bobbin device for textile machine

A technology of textile machinery and bobbins, applied in the field of bobbin devices, which can solve problems such as unwinding forming, affecting yarn quality, poor yarn winding, etc., to avoid breakage, improve winding quality, and simple and convenient installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

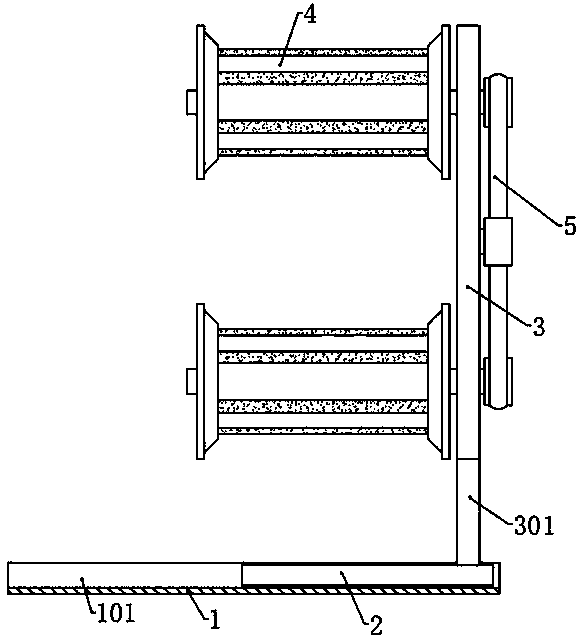

[0030] Please refer to the accompanying drawings, the present invention provides a technical solution: a yarn bobbin device for textile machinery, including a base 1, a chute 101 is provided in the middle of the top surface of the base 1, and a moving seat 2 is slidably connected to the chute 101, The top surface of the moving seat 2 is symmetrically fixed with a fixed rod 301, and the top of the fixed rod 301 is jointly fixed with a fixed plate 3, and the left side of the fixed plate 3 is provided with four bobbin assemblies 4 in a rectangular array, and the right side is provided with a drive component 5;

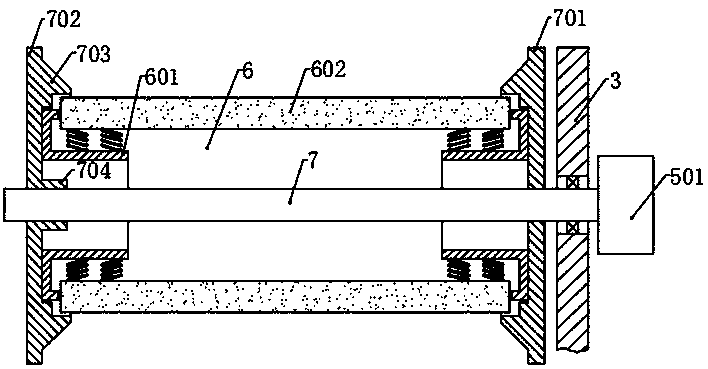

[0031] Yarn bobbin assembly 4 comprises the rotating shaft 7 that is vertical and rotationally connected with fixed bar 301, and the left section of rotating shaft 7 is provided with movable baffle 702, and the right side of movable baffle 702 is provided with fixed baffle 701, and the rotating shaft The right end on 7 passes through the fixed plate 3 and is corresponding...

Embodiment 2

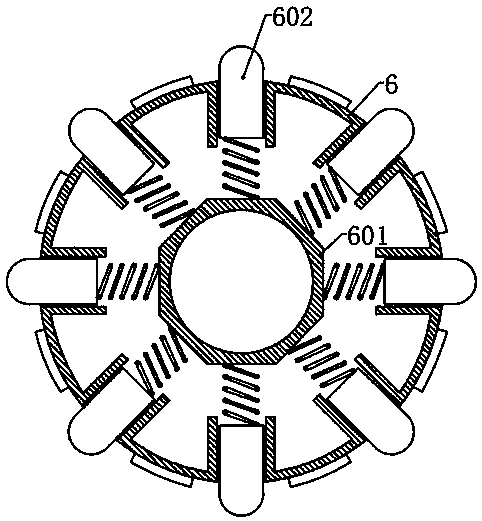

[0038] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a circular yarn guiding platform 703 is symmetrically fixed on the inner side of the fixed baffle 701 and the moving baffle 702, and the outer circle side of the yarn guiding platform 703 The wall is inclined to the direction of the rotating shaft 7, and the center of the inner surface of the yarn guide table 703 is provided with a circular receiving groove, and the center of the circular side wall of the receiving groove is provided with a mounting groove, and the two ends of the cylinder body 6 are respectively located In the installation groove, the two ends of the telescopic block 602 are respectively located in the accommodation groove; when the cylinder 6 is installed, the two ends of the cylinder 6 are respectively located in the installation grooves on both sides, so that the position of the cylinder 6 is limited so that it is in line with the rotation The shaft...

Embodiment 3

[0042] The structure of this embodiment is basically the same as that of Embodiment 2, the difference being that a spring groove 302 is provided at the position corresponding to the tension wheel 502 on the fixed plate 3, and a moving block 503 is slidably connected to the spring groove 302, and the outer side of the moving block 503 A spring is provided between the end and the outer end of the spring groove 302, and the tensioning wheel 502 is rotationally connected with the moving block 503. Through the action of the spring and the moving block 503, the tensioning wheel 502 can always tension the transmission belt, improving the stability of the transmission. sex.

[0043] The side wall of the chute 101 is provided with a limit groove along the length direction, and a limit bar is fixed on the outer surface of the vertical rod, and the limit bar is slidably connected in the limit groove to prevent the movable seat 2 from accidentally breaking away from the base 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com