Rubber hose braid processing system and processing technology

A processing system and rubber hose technology, which is applied in the rubber hose braided layer processing system and processing technology field, can solve the problem of reducing the production and processing efficiency of rubber hoses, the cumbersome process of rubber hose braided layer, and the cumbersome process of manual winding and braiding, etc. problems, to achieve the effect of shortening the production and processing cycle, improving production efficiency, and avoiding knotting and jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

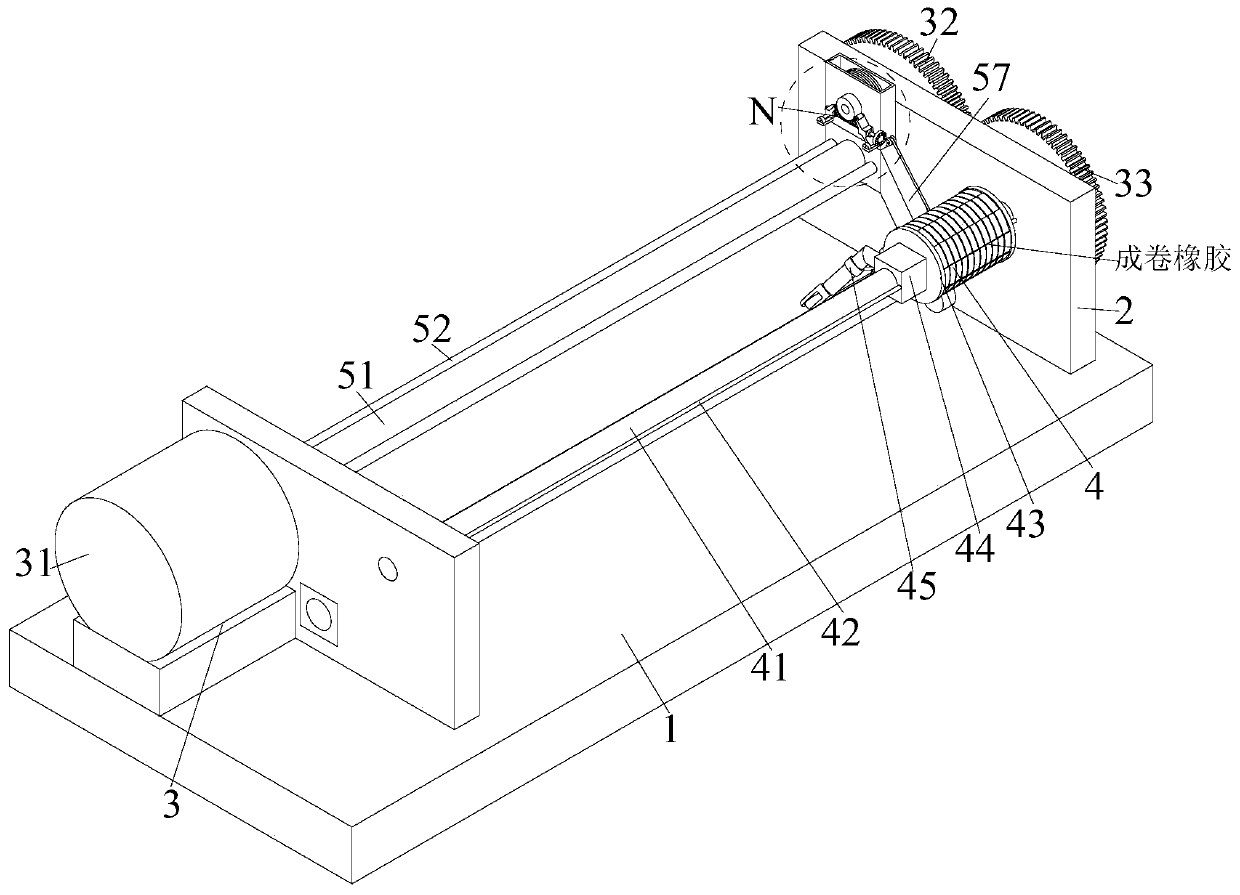

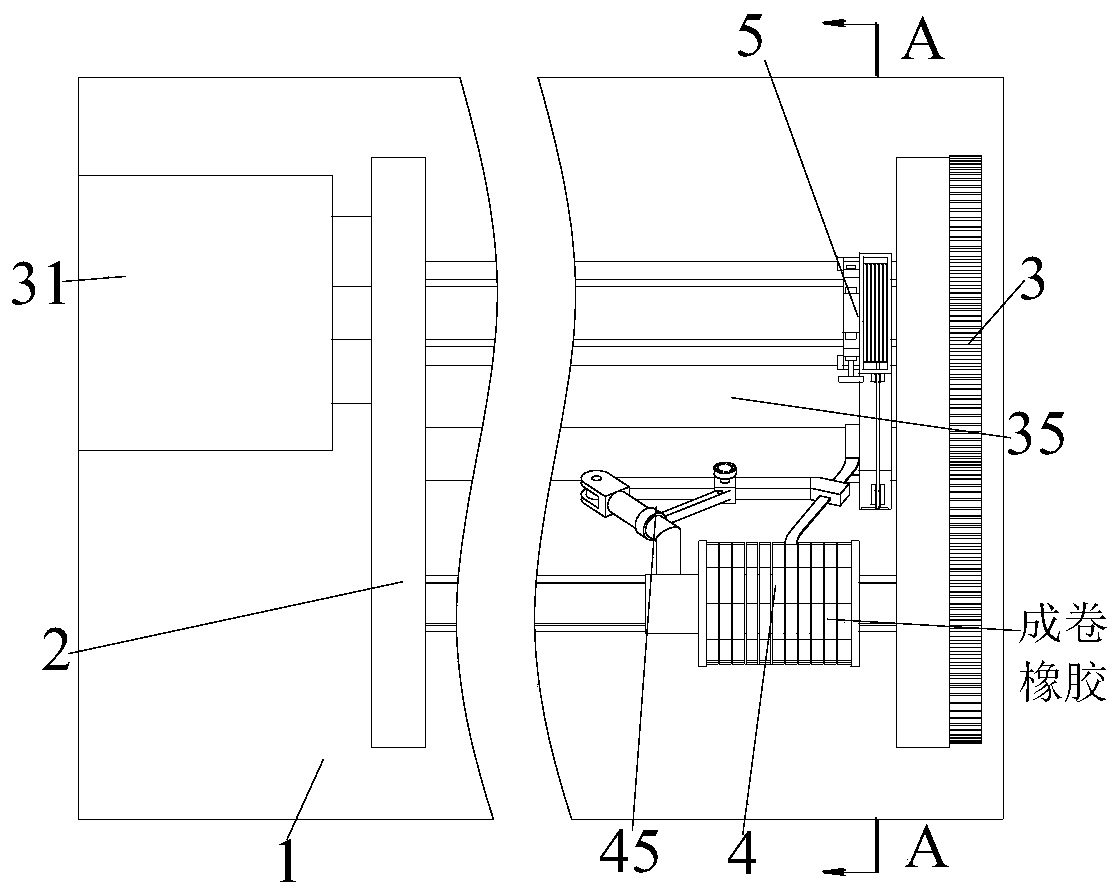

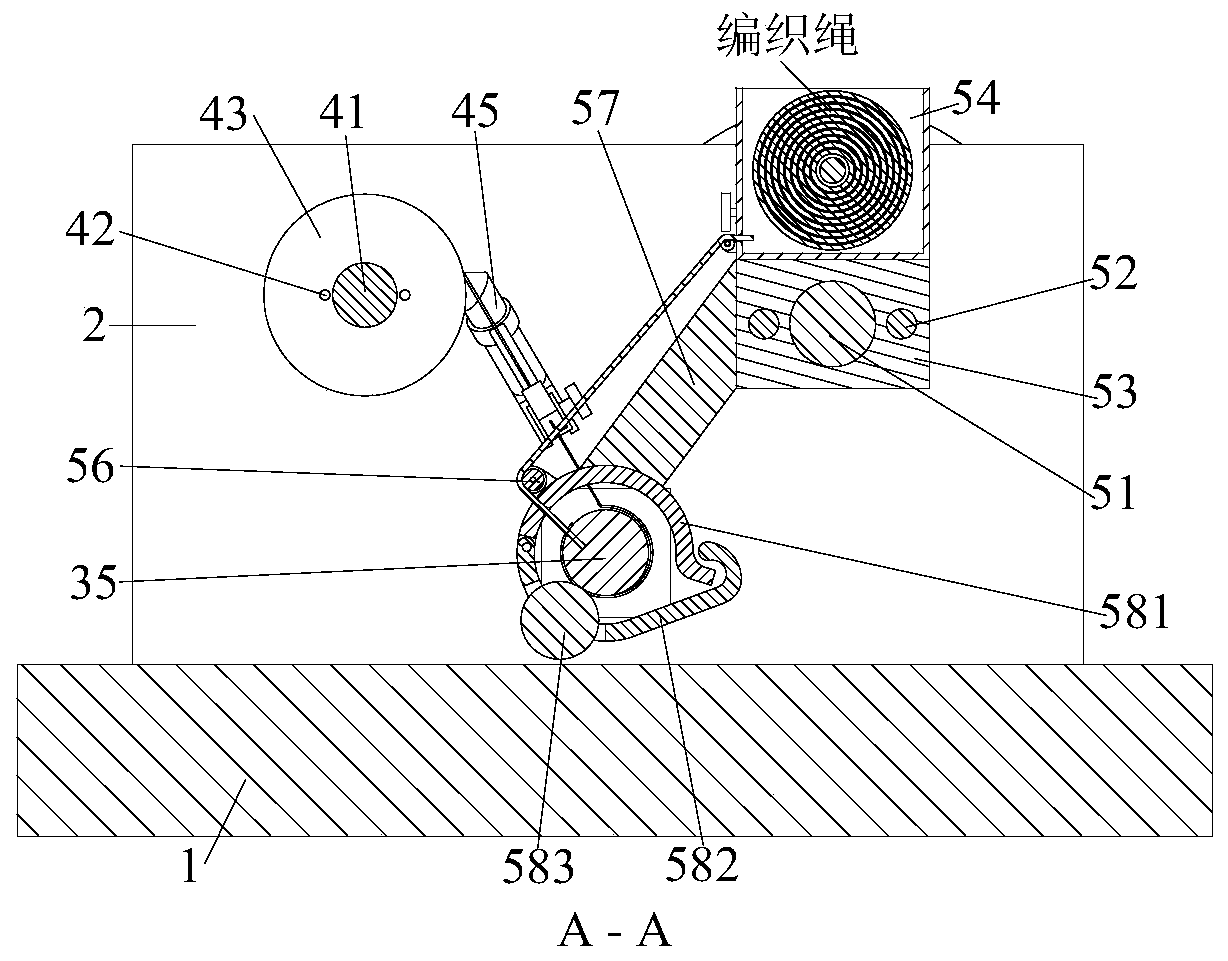

[0038] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0039] A rubber hose braid processing system, comprising a workbench 1, two side plates 2, a drive device 3, a glue wrapping device 4 and a winding device 5, the upper end of the workbench 1 is symmetrically installed with side plates 2, the side A driving device 3 is installed on the outside of the plate 2, a glue wrapping device 4 is installed on the right inside of the side plate 2, and a winding device 5 is arranged on the rear side of the glue wrapping device 4; wherein:

[0040] The driving device 3 includes a rotating motor 31, a drive gear 32, a driven gear 33, a pipe making gear 34 and a pipe making roller 35. The rotating motor 31 is installed on the left side of the upper end of the workbench 1 through a motor mounting plate, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com