Scaffold climbing and sliding system of tower crane and scaffold and standard joint of system

A technology of tower crane and standard section, applied in cranes and other directions, can solve problems such as hidden safety hazards, large contact stress, and excessive wheel pressure of the guide wheel structure of the sleeve frame, so as to reduce the concentration force, the contact surface is large, and the transportation is well controlled. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

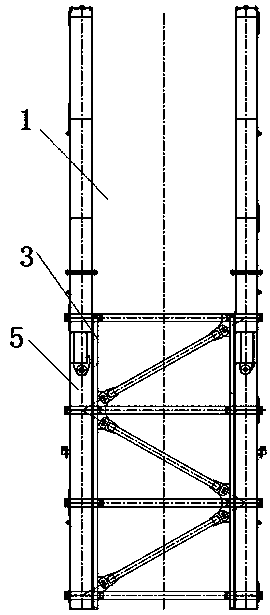

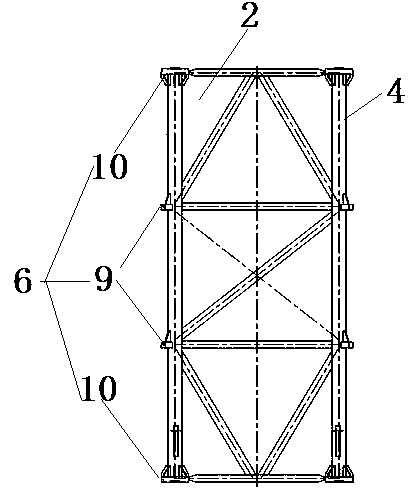

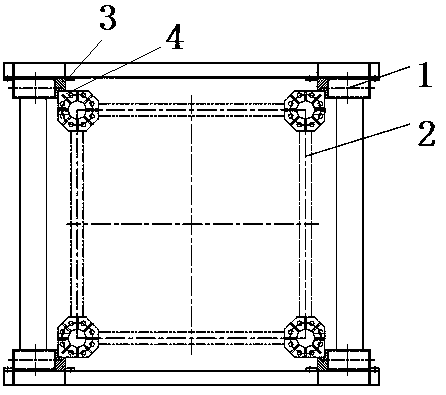

[0029] A specific embodiment of the tower crane cover frame climbing and sliding system involved in the present invention, such as Figure 1-Figure 5 As shown, the sliding system includes a sleeve frame 1 and a standard section 2. The outer structure and size of the sleeve frame 1 are basically consistent with the prior art. It has four support columns 3 spaced apart and arranged in a rectangular array. Each support column 3 are extended and arranged in the up and down direction, and the reinforcement beams are used between two adjacent support columns 3 to realize reinforced support. The structure of the standard section 2 is also basically consistent with the prior art. It has four main chords 4 respectively correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com