A kind of polyethylene glycol derivative and its preparation method and application

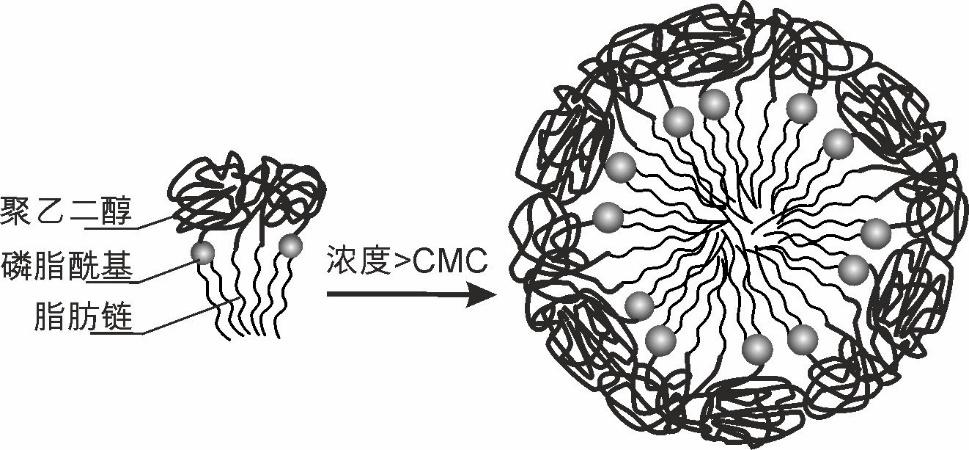

A technology based on polyethylene glycol and polyethylene glycol groups, which can be used in pharmaceutical formulations, toiletry preparations, cosmetic preparations, etc., and can solve the problem of difficulty in accurately controlling the distribution and quantity of hydrophobic chains, reducing tissue penetration, and affecting Precise tuning of the kinetics of hydrophobic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0097] The molecular weight of diisopropylethylamine used in the following examples is 129 Da, and the manufacturer is Beijing Chemical Plant. used in the following examples N,N -Dimethylformamide is anhydrous DMF, the purity is analytically pure, and the manufacturer is Beijing Chemical Plant.

[0098] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained fr...

Embodiment 1

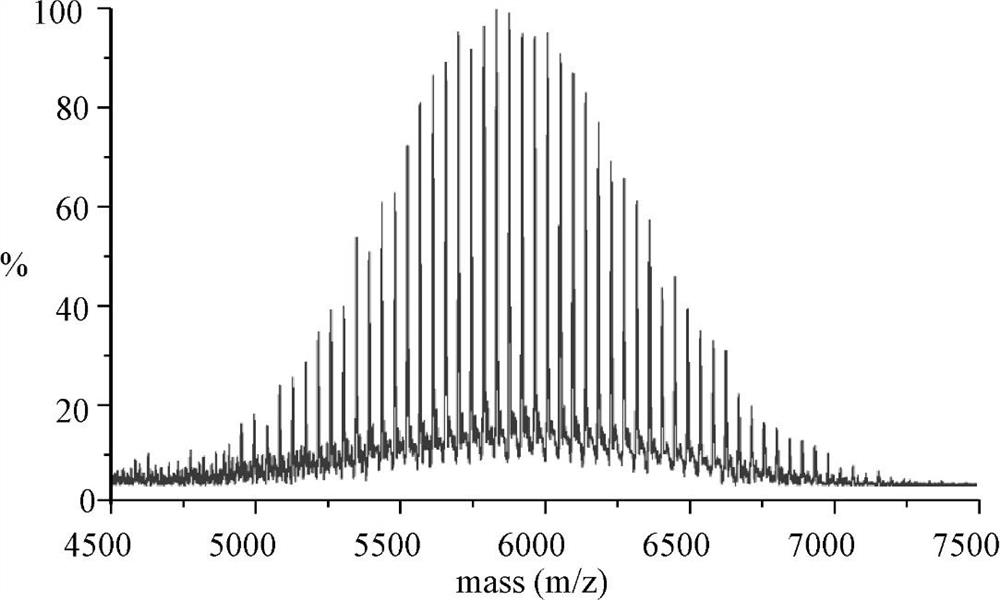

[0102] Example 1 Synthesis of three aliphatic chain-polyethylene glycol derivatives (1DSPE, 1 n-octadecanethiol)

[0103] Weigh out 50 mg DSPE in a 10 mL round bottom glass flask and dissolve it in 100 µL N,N - In dimethylformamide, add 12 µL of diisopropylethylamine to obtain a solution (a).

[0104] Use a 2 ml weighing bottle to weigh 334 mg of end-group-substituted polyethylene glycol OPSS-PEG5000-SCM (polyethylene glycol with an average molecular weight of 5000 Da and end groups of dithiopyridyl and succinimide carboxymethyl ester respectively). Alcohol, purchased from Beijing Jiankai Technology Co., Ltd., product number A5109), was dissolved in 400 µL DMF to obtain solution (2).

[0105]The solution (2) was added into the round bottom flask with the solution (1) for mixing, stirred by magnetic force, and reacted at room temperature for 4 hours under the protection of nitrogen. Afterwards, nitrogen protection was removed, and 100 µL of 0.5 M hydrochloric acid solution w...

Embodiment 2

[0107] Example 2 Synthesis of three aliphatic chain-polyethylene glycol derivatives (1DSPE, 1 n-octyl thiol)

[0108] Weigh 50 mg of DSPE in a 10 mL round bottom glass flask, dissolve it in 100 µL of DMF, and add 12 µL of diisopropylethylamine to obtain solution (a).

[0109] Use a 2 ml weighing bottle to weigh 334 mg of terminal-substituted polyethylene glycol MAL-PEG5000-SCM (polyethylene glycol with an average molecular weight of 5000 Da and terminal groups of maleimide and succinimide carboxymethyl ester respectively). Diol, purchased from Beijing Jiankai Technology Co., Ltd., product number A5003), was dissolved in 400 µL DMF to obtain solution (2).

[0110] Add 15 µL of 1-octanethiol (molecular weight 146, purchased from Beijing Bailingwei Technology) to solution (2), and react for 1 hour under nitrogen protection. The obtained reaction solution was added into the round bottom flask with solution (1) for mixing, stirred by magnetic force, and reacted for 4 hours at room...

PUM

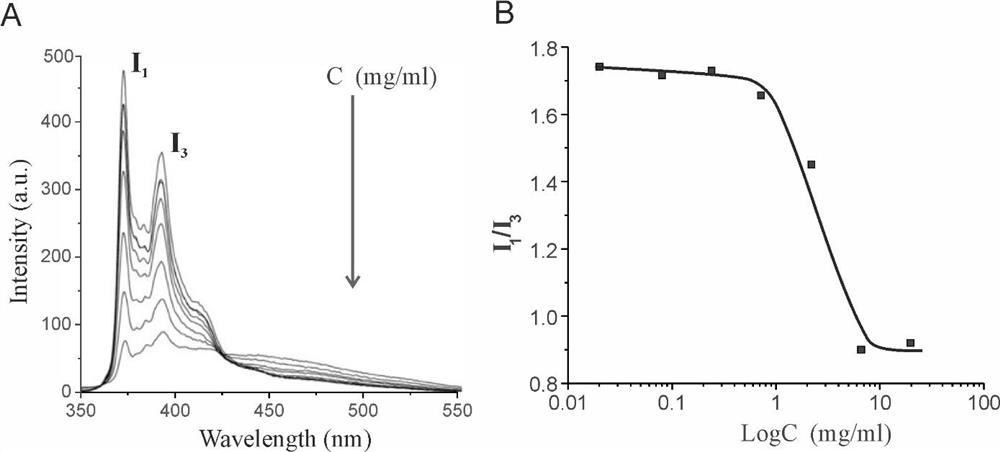

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration (mass) | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com