A kind of preparation method of cross-linked polycaprolactone material

A technology of polycaprolactone and caprolactone is applied in the field of preparation of cross-linked polycaprolactone materials, and can solve the application limitation of regulating cross-linked polycaprolactone, cross-linked polycaprolactone crystallization speed, and cross-linked polycaprolactone. Caprolactone complex and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In order to effectively control the crystallization rate of cross-linked polycaprolactone material, the application provides a preparation method of cross-linked polycaprolactone material, the preparation method is due to the introduction of styrene-acrylonitrile copolymer (SAN), and by Electron beam irradiation can effectively regulate the crystallization speed of cross-linked polycaprolactone. Specifically, the embodiment of the present invention discloses a preparation method of a cross-linked polycaprolactone material, comprising the following steps:

[0030] Melt-blending polycaprolactone and styrene-acrylonitrile copolymer with a crosslinking agent, and then melt-blending to obtain polycaprolactone blend pellets;

[0031] Compressing the polycaprolactone composite pellets to obtain a polycaprolactone sheet;

[0032] The polycaprolactone sheet is irradiated with an electron beam to obtain a cross-linked polycaprolactone material.

[0033] In the process of prepar...

Embodiment 1

[0040] Put the PCL pellets and SAN pellets in a vacuum dryer at 40°C and 80°C for 12 hours, respectively; melt and blend the dried PCL and SAN in an internal mixer at 200°C and 40rpm at a mass ratio of 100:0 After 2 minutes, add 1.75% cross-linking agent TAIC, continue to melt and blend for 3 minutes, and discharge to obtain polycaprolactone blend pellets; press the blend pellets into a sheet with a thickness of 1 mm in a film pressing machine , the film pressing temperature is 120°C, melting for 2 minutes, depressurizing 3 times, and keeping the pressure at 10MPa for 1 minute; put the pressed sheet into a polyethylene bag, and irradiate it with electron beams, and the irradiation dose is 20KGy. Cross-linked polycaprolactone material.

Embodiment 2

[0042] The preparation process is the same as in Example 1, except that the mass ratio of PCL to SAN is 95:5, and the irradiation dose is 50KGy.

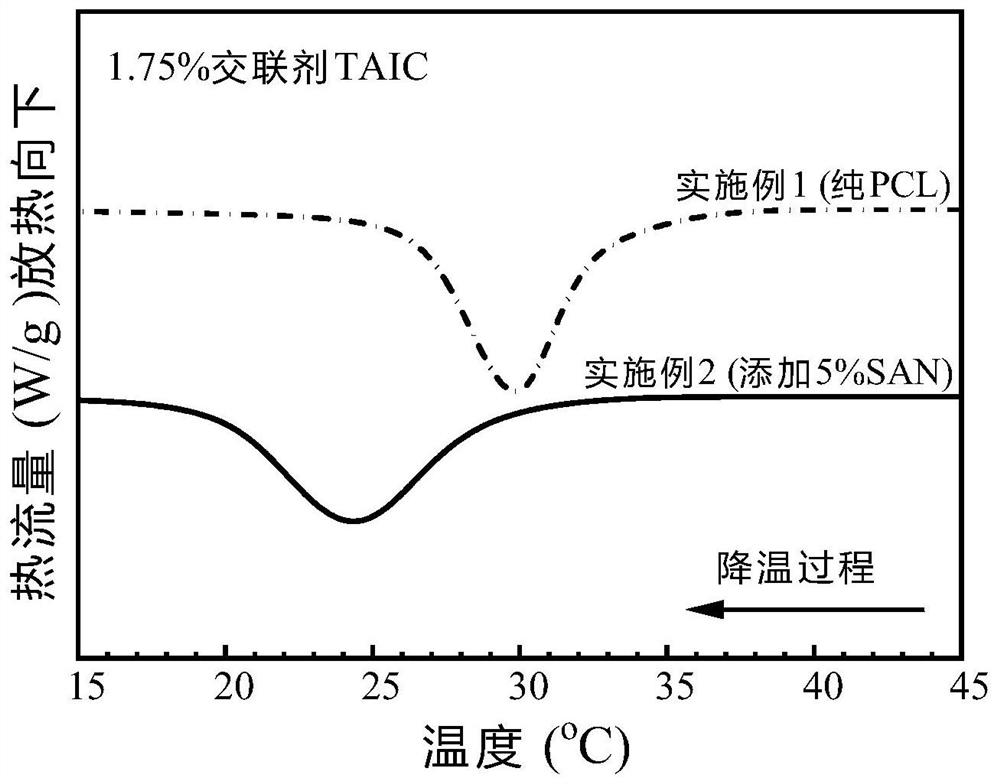

[0043] figure 1 The DSC curve of the cross-linked polycaprolactone material prepared for embodiment 1 and embodiment 2 is cooled at 7.65°C / min after melting; the crystallization peak temperature corresponding to the cooling curve in the figure is an important index reflecting the crystallization behavior of polycaprolactone, The crystallization peak temperature of the crosslinked polycaprolactone material (adding 5% SAN) prepared in embodiment 2 is lower than the crystallization peak temperature of embodiment 1 (pure PCL), illustrating that adding SAN can slow down the crystallization of crosslinked polycaprolactone Crystallization speed.

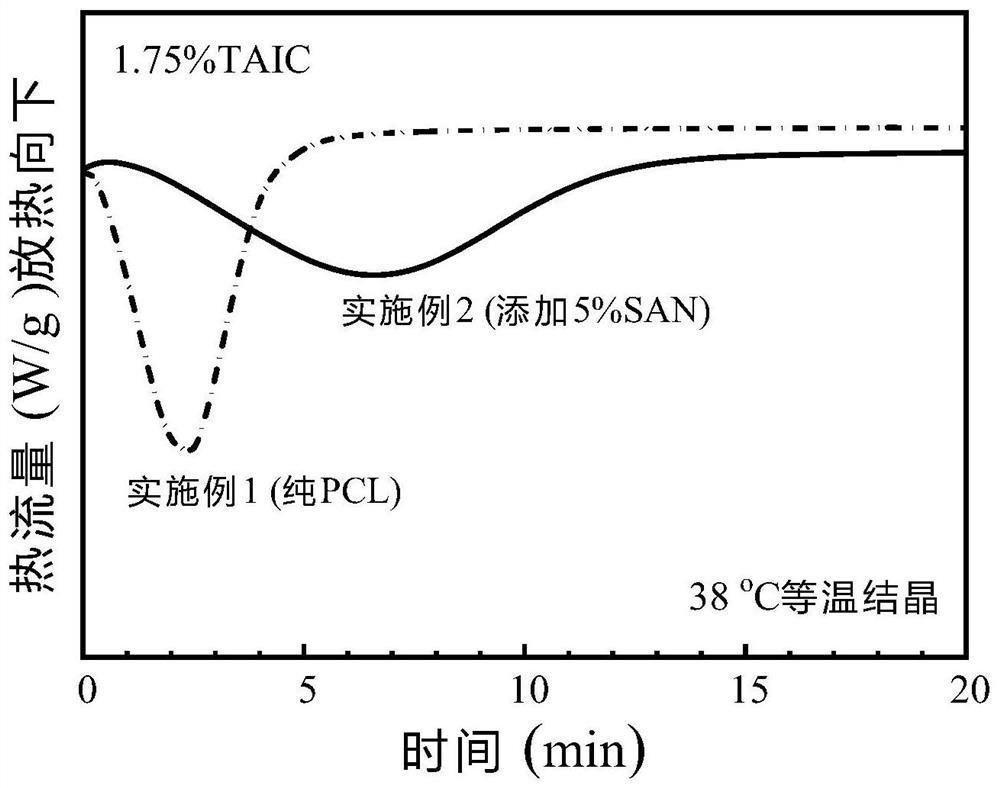

[0044] figure 2 The DSC curve of the cross-linked polycaprolactone material prepared for Example 1 and Example 2 isothermal crystallization at 38°C; through the isothermal crystallization test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com