Shear wall internal corner formwork splicing joint edge covering construction method

A technology of an inside corner formwork and construction method, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, etc., can solve the problem of irregularity and affect the decoration effect. , inclusions and other problems, to ensure the quality of construction, the construction method is simple and economical, and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in further detail below.

[0018] The method of the present invention for the construction method of the joint seam and hemming of the internal corner template of the shear wall is characterized in that it comprises the following steps:

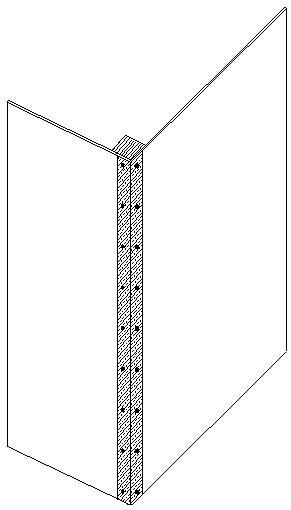

[0019] The edging leather is cut into strips with a width of 8-15 cm, and folded into an L shape for use;

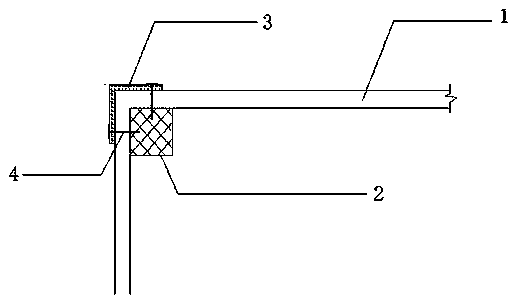

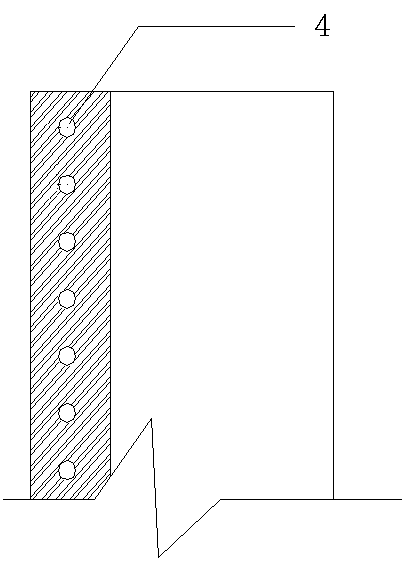

[0020] After the internal corner template 1 is spliced, wrap the L-shaped edging skin 2 along the two sides of the internal corner template seam direction, and use the long nail 3 to evenly drive in the two folds of the L-shaped edging skin along the seam direction And nailed into the internal corner bracket 4, the long nails are driven at a distance of 4-6 cm; the length of the long nails should be greater than the thickness of the template;

[0021] Install the formwork after coating the release agent on the inner corner formwork and the outer facade of the edging skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com