Self-oil-removing cleaning window for kitchen

A kitchen and cleaning technology, applied in the field of smart home, can solve problems such as difficult cleaning of window glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

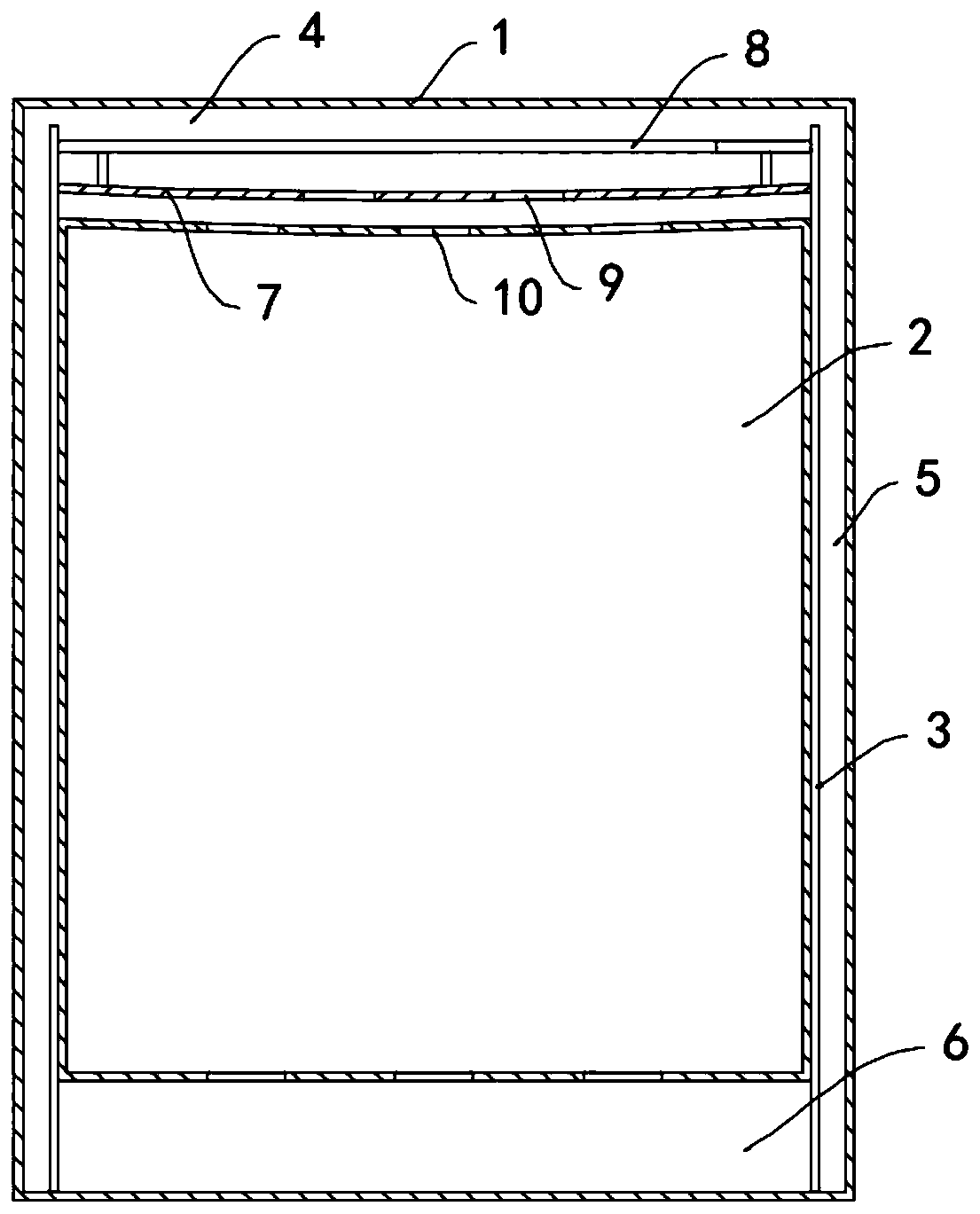

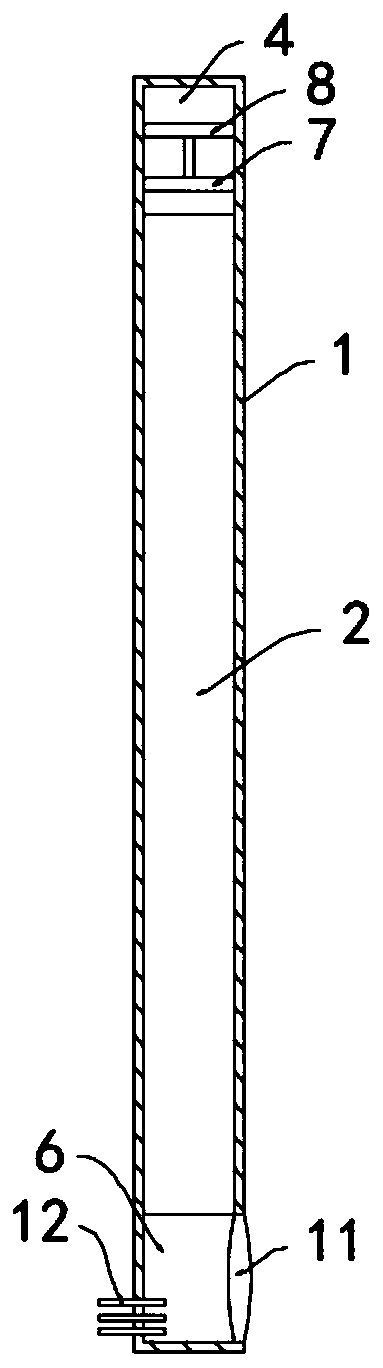

[0019] Such as Figure 1-2 As shown, a self-greasing and cleaning window for kitchens includes a frame body 1 and a light-transmitting glass 2 installed on the inner side wall of the frame body 1, and two vertical partition plates are fixedly installed in the frame body 1 3. The partition plate 3 divides the interior of the frame body 1 from top to bottom into a liquid storage chamber 4, an evaporation channel 5, and an evaporation chamber 6. The evaporation channel 5 is located on both sides of the frame body 1, and the upper end of the evaporation channel 5 and the The lower end is connected with the liquid storage chamber 4 and the evaporation chamber 6 respectively, the liquid storage chamber 4 is filled with a cleaning solution, and the cleaning liquid is an ethanol solution, and the inner wall of the liquid storage chamber 4 is sealed and slidably connected with a baffle 7, and the baffle 7 The upper surface of the upper surface is fixedly connected with a floating plate...

Embodiment 2

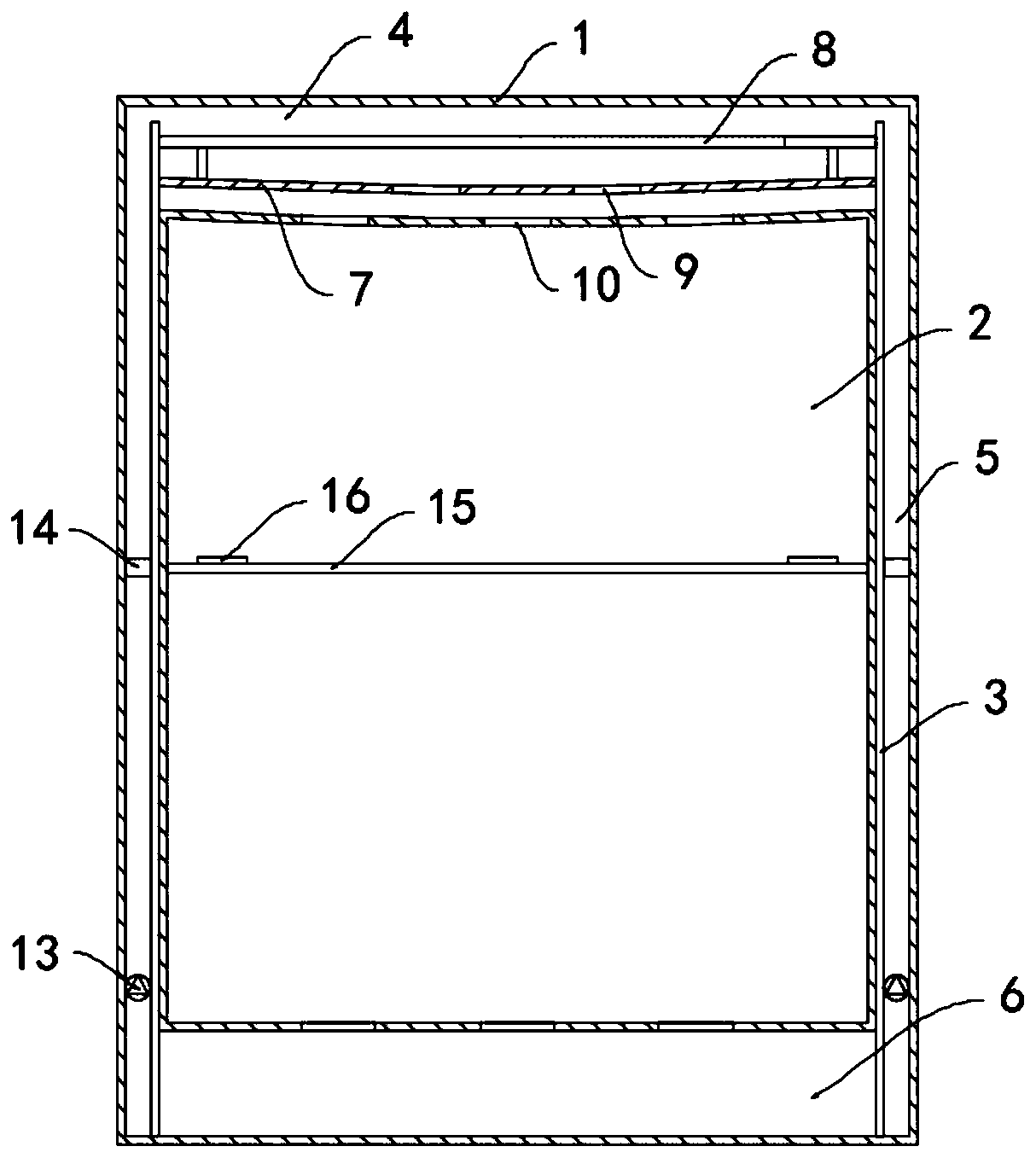

[0023] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a pressure valve 13 is provided in the evaporation channel 5, a permanent magnet ring 14 is slidably connected to the inner wall of the evaporation channel 5, and a permanent magnet ring 14 is slidably connected to the surface of the transparent glass 2. The scraping strip 15 is attached with a magnetic strip 16 on the side wall of the scraping strip 15, and the magnetic strip 16 and the permanent magnetic ring 14 attract each other with different poles.

[0024] In this embodiment, when the air pressure in the evaporation chamber 6 is low, the pressure valve 13 can close the evaporation channel 5. With the evaporation of the cleaning liquid in the evaporation chamber 6, the pressure in the evaporation chamber 6 gradually increases until the pressure reaches a certain value. At this time, the pressure valve 13 is opened, and the gaseous cleaning liquid enters the liquid storage ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com