Current transformer assembly

A technology for current transformers and components, applied in the transformer/inductor shell, transformer/reactor installation/support/suspension and other directions, can solve the problems of easy shaking, lack of support and positioning structure, unfavorable assembly, etc., to achieve convenient installation Simple installation and assembly process, and the effect of preventing axial shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

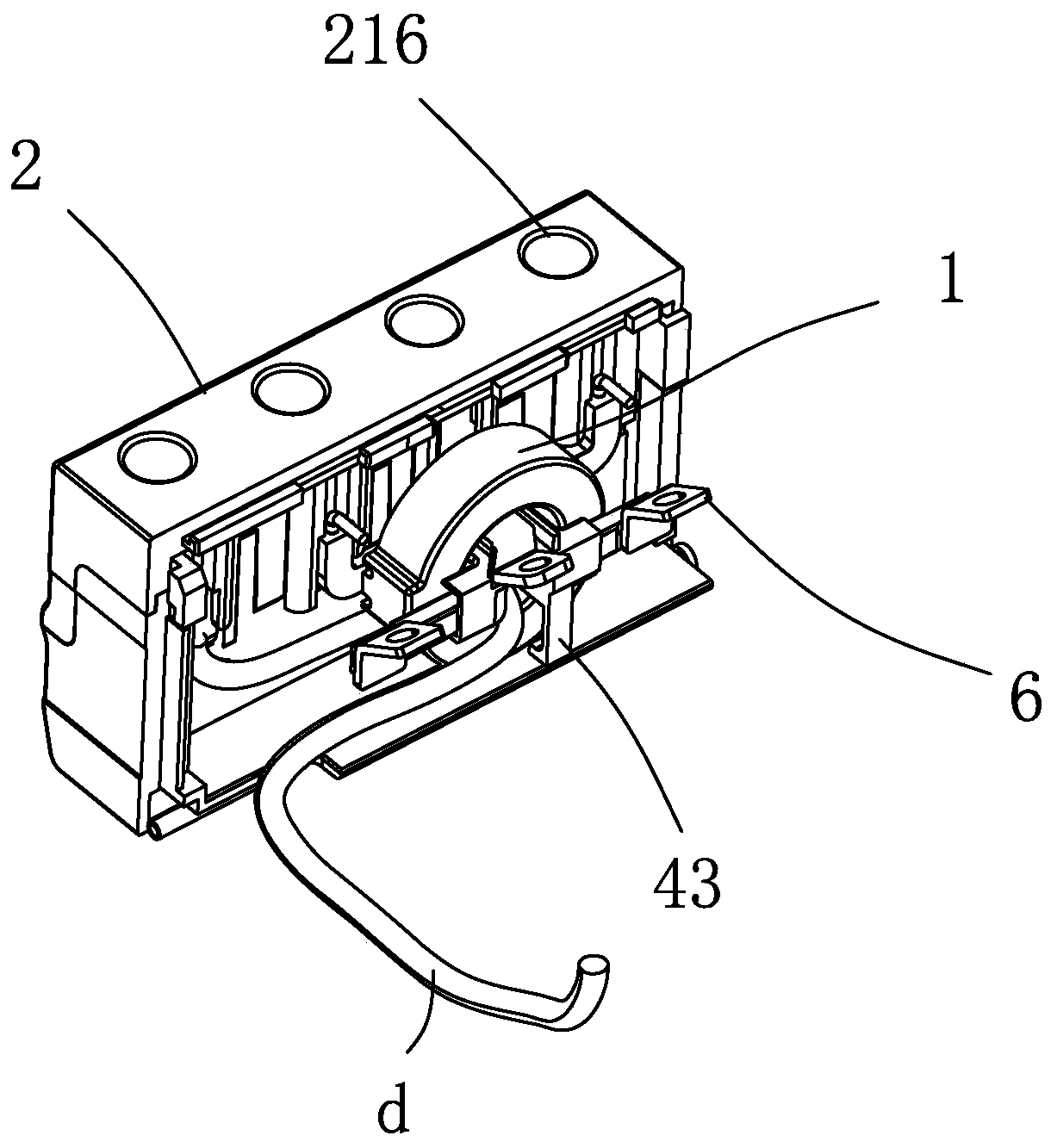

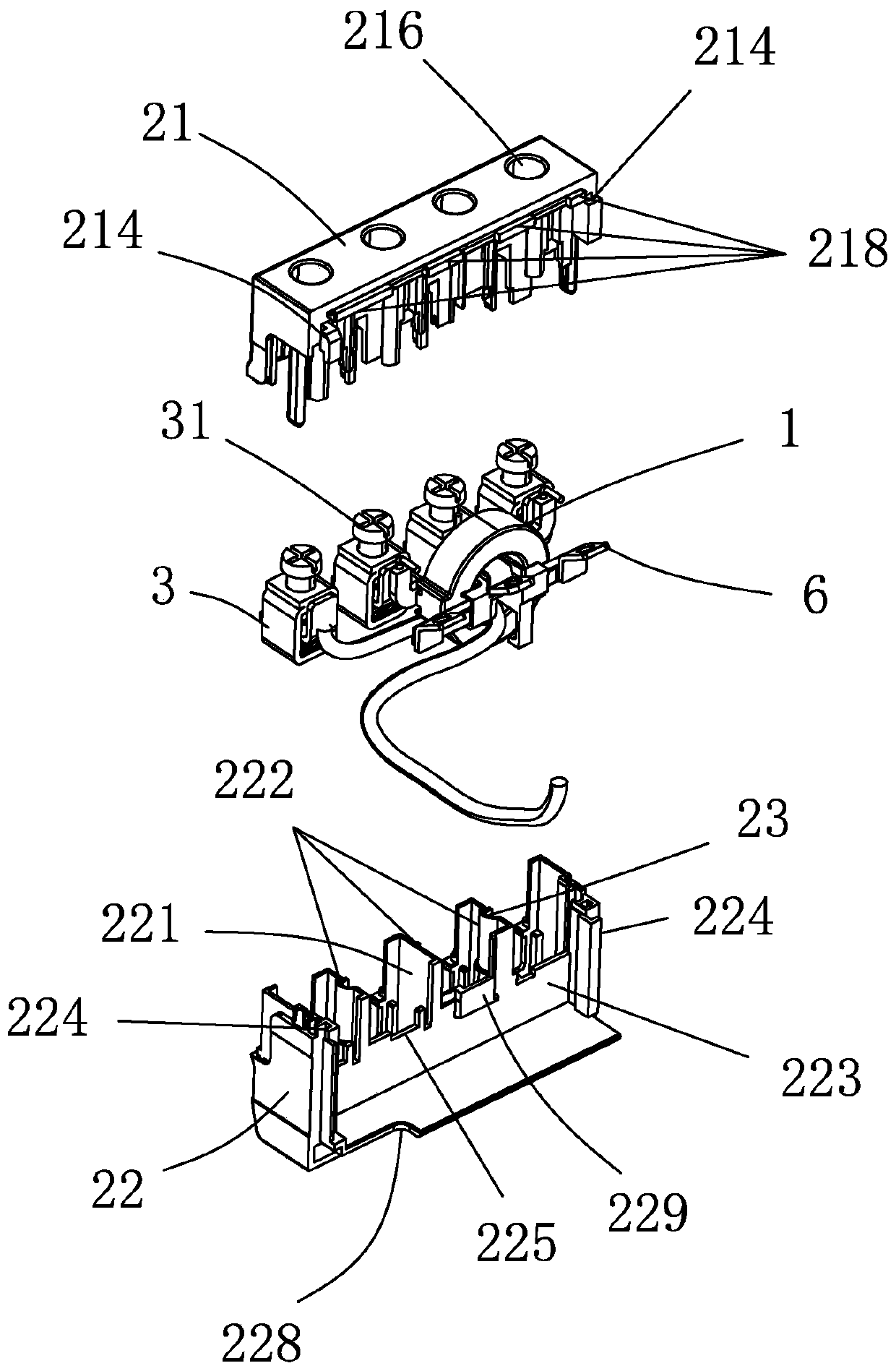

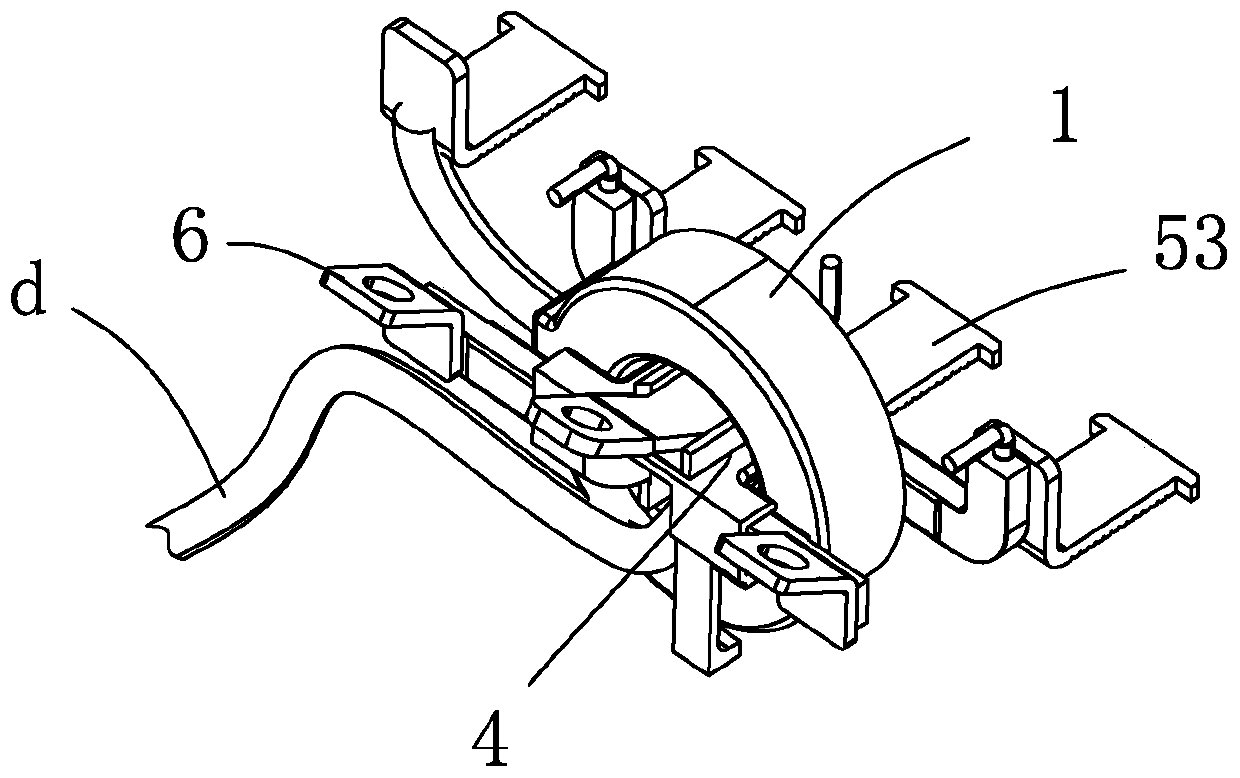

[0045] A current transformer assembly of the present invention is used to form a component of a multi-level circuit breaker, and its embodiment is as follows Figure 1-15 Shown: includes a ring-shaped current transformer 1, a housing 2 for accommodating the current transformer 1, a number of current-carrying parts, and a terminal block 3 correspondingly connected to these current-carrying parts, and is installed in cooperation with the current transformer 1 The fixed part also includes a support 4, the current-carrying parts are made of rigid conductive material, have good conductivity and are not easy to bend, the support 4 is made of insulating material, and these current-carrying parts are connected with the support 4 at the same time Fitted together and fixed in the inner hole of the current transformer 1, the support member 4 can support and position the current-carrying parts penetrating into the current transformer 1, and at the same time enhance the insulation function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com