Display panel and preparation method thereof

A display panel and color resistance technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, diodes, etc., can solve the problems of insufficient blackness and color cast, reduce the half-peak width, low reflectivity, and improve the color of the display screen. domain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

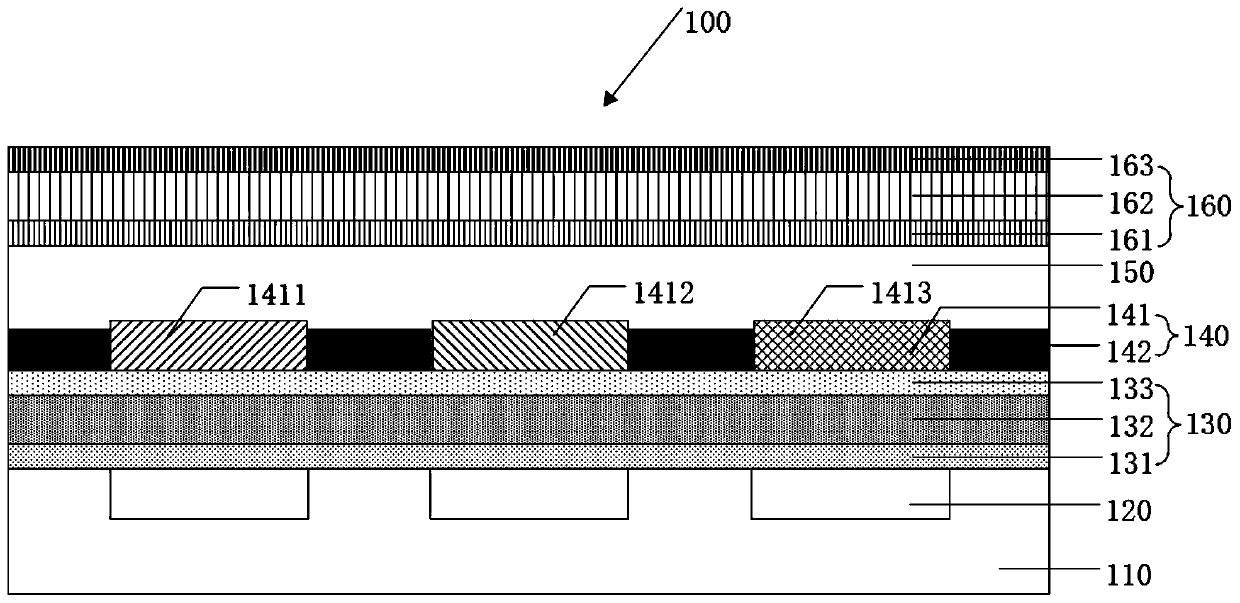

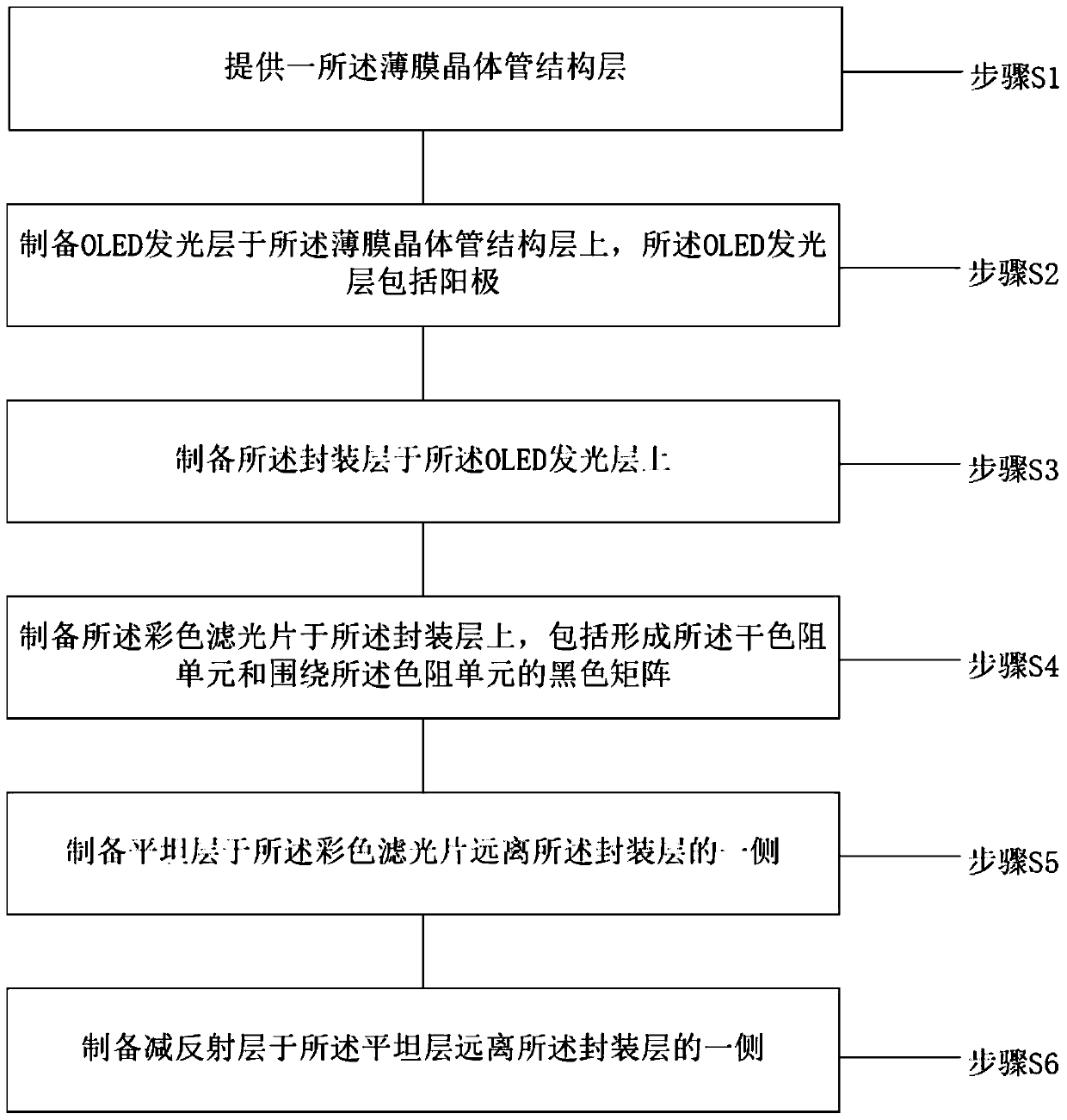

[0044] see figure 1 , figure 1 This embodiment provides a schematic structural view of the display panel 100 , the display panel 100 includes a thin film transistor structure layer 110 , an OLED light emitting layer 120 , an encapsulation layer 130 , a color filter 140 , a flat layer 150 and an anti-reflection layer 160 .

[0045] Specifically, the thin film transistor structure layer 110 includes a substrate layer; an active layer disposed on the substrate layer; a gate insulating layer disposed on the active layer; a gate layer disposed on the gate insulating layer; a pixel definition layer, It is disposed on the gate layer; since the improvement of the present invention lies in the anti-reflection layer 160 , the description of the thin film transistor structure layer 110 will not be repeated here.

[0046] The OLED light emitting layer 120 is disposed on the pixel definition layer, and the OLED light emitting layer 120 includes an anode.

[0047] The encapsulation layer ...

Embodiment 2

[0070] The display panel in this embodiment also includes several color-resist units 141 and a black matrix 142 surrounding the color-resist units, which are roughly the same as the corresponding structure in Embodiment 1. For the same structure, refer to the corresponding description in Embodiment 1. , which will not be repeated here. The main difference between the two is that the thickness of the blue color-resist unit 1413 is smaller than that of the red color-resist unit 1411 or the green color-resist unit 1412 . see Figure 4 , Figure 4 Shown is a schematic structural diagram of the display panel 100 provided in this embodiment.

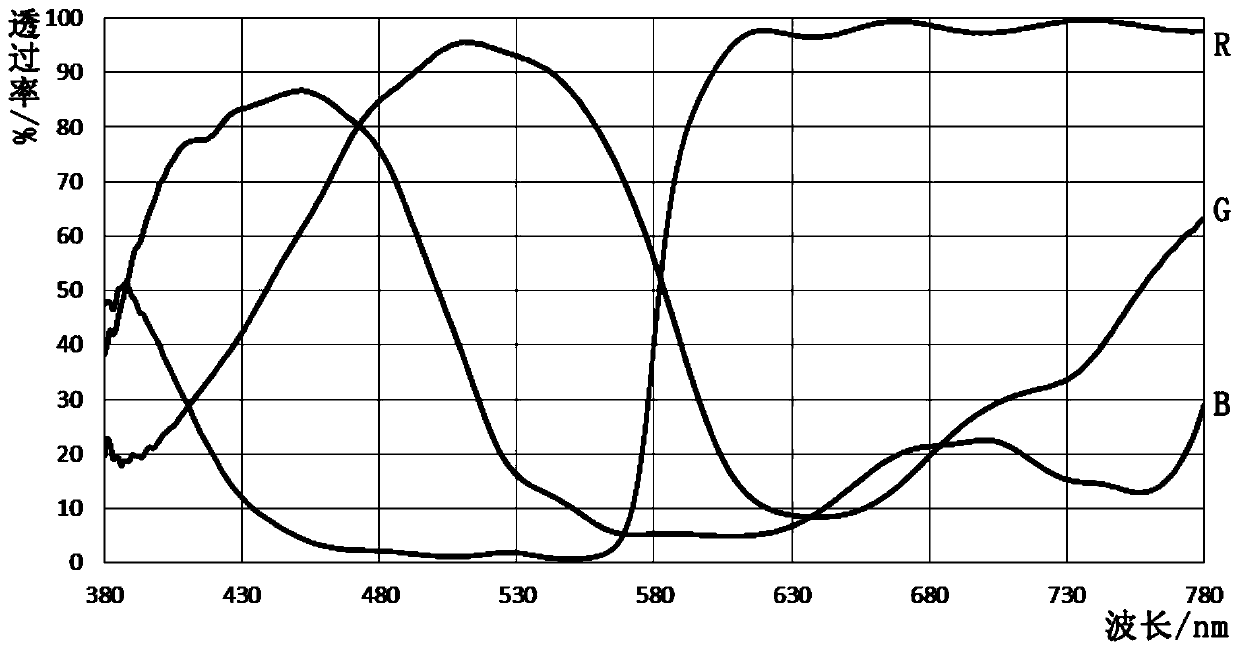

[0071] see Figure 5 , Figure 6 and Figure 7 , Figure 5 Schematic diagram of the transmittance when the thickness of the film layer of the red color resist unit provided in this embodiment is 1um, 2um, 3um, 4um; Figure 6 Schematic diagram of the transmittance when the thickness of the film layer of the green color resist unit provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com