Lamb wave resonator and preparation method thereof

A Lamb wave resonator, high-order Lamb wave technology, applied in electrical components, impedance networks, etc., can solve the problem that low-order modes are difficult to be effectively suppressed, and achieve the effect of avoiding abnormal operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

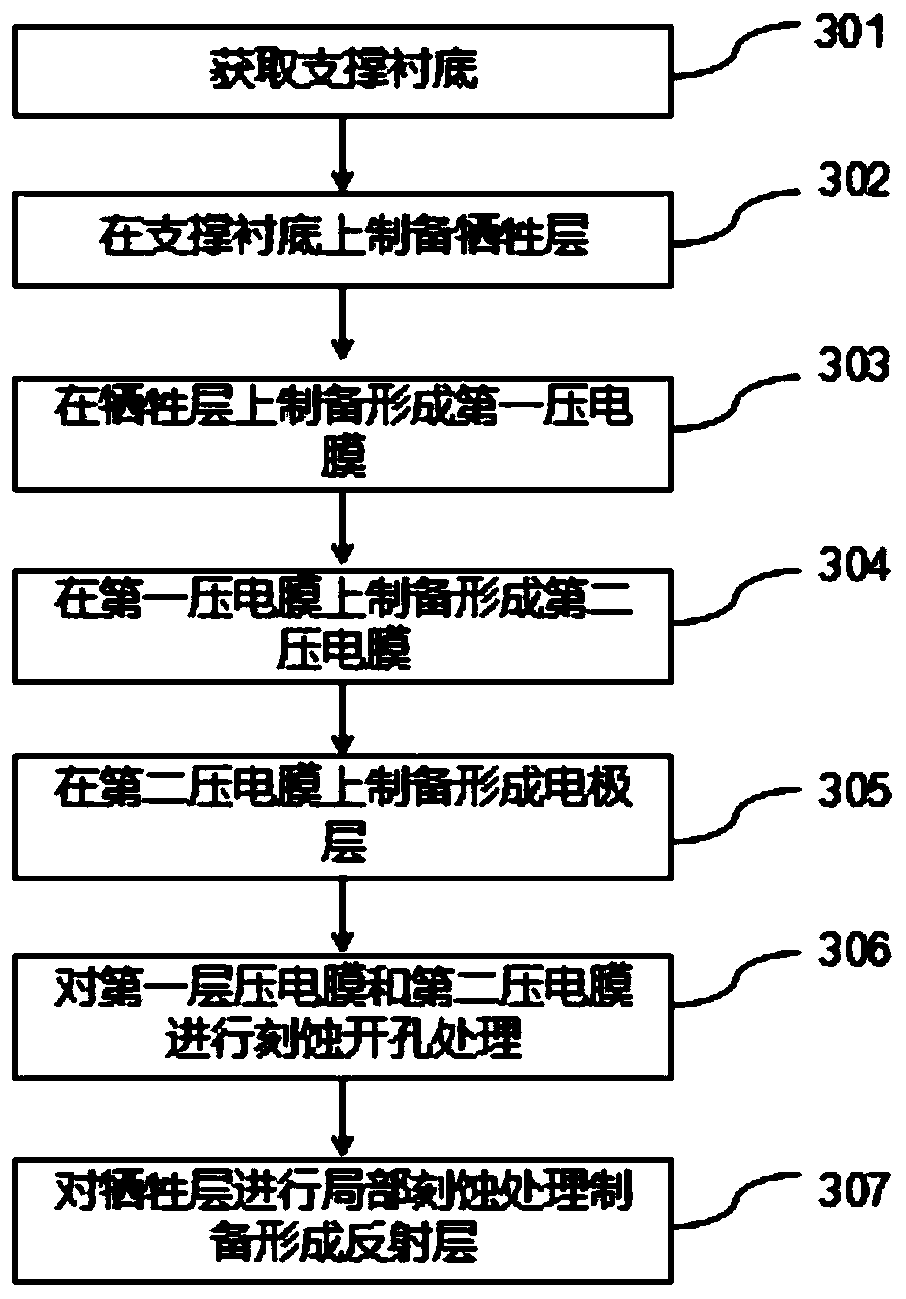

[0056] Another aspect of the embodiment of the present application provides a method for preparing a Lamb wave resonator, including the following steps:

[0057] Obtain a supporting substrate 1;

[0058] preparing and forming a device structure layer on the supporting substrate 1;

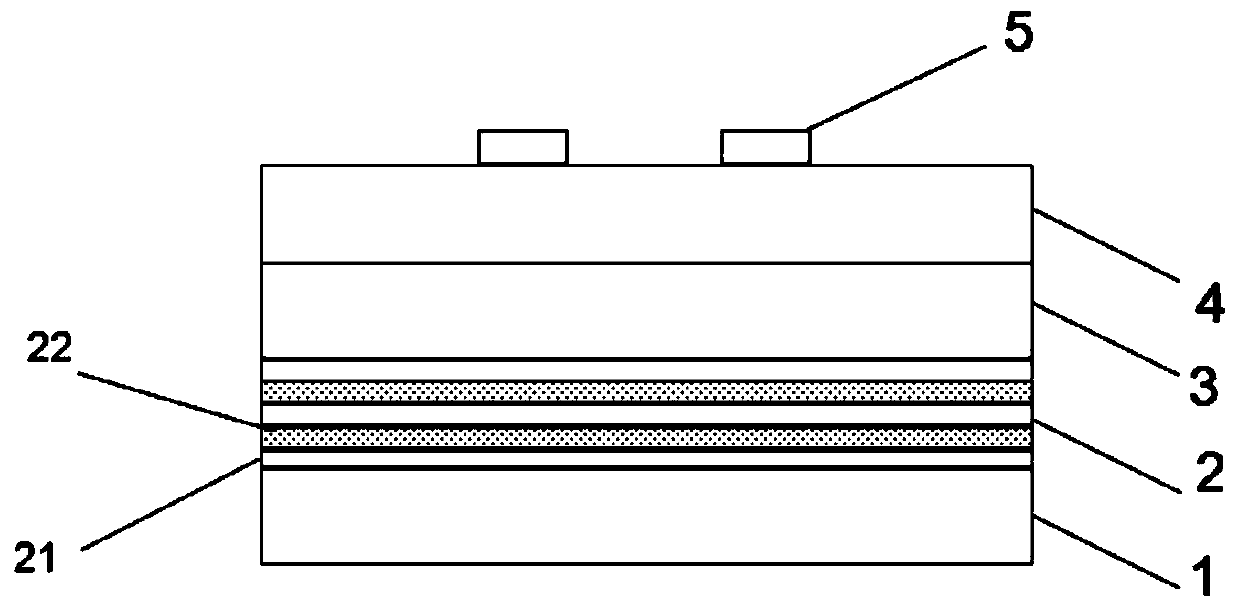

[0059] The device structure layer includes: reflective layer 2, first piezoelectric film 3, second piezoelectric film 4 and electrode layer 5, reflective layer 2, first piezoelectric film 3, second piezoelectric film 4 and electrode layer 5 are stacked in sequence connect;

[0060] The cooperation between the first piezoelectric film 3 and the second piezoelectric film 4 can eliminate or reduce the unnecessary piezoelectric coefficient for exciting high-order Lamb waves.

[0061] In the embodiment of the present application, the first piezoelectric film 3 and the second piezoelectric film 4 are laminated to obtain a piezoelectric film structure; the piezoelectric coefficient and elastic constant ...

Embodiment 1

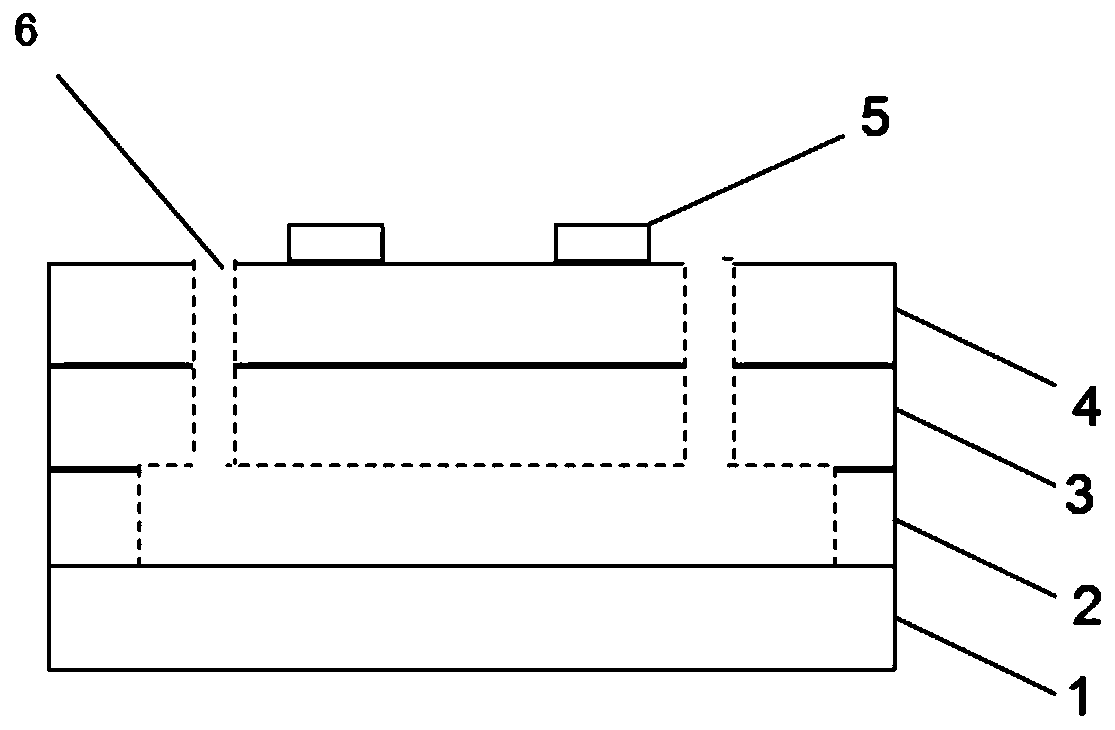

[0088] Embodiment 1 of the present application provides a Lamb wave resonator, including: a support substrate 1, an air reflection layer 2, a first piezoelectric film 3, a second piezoelectric film 4, and an electrode layer 5;

[0089] The supporting substrate 1, the reflective layer 2, the first piezoelectric film 3, the second piezoelectric film 4 and the electrode layer 5 are sequentially stacked and connected;

[0090] One of the first piezoelectric film 3 and the second piezoelectric film 4 can excite high-order Lamb waves, and the other one can eliminate or reduce piezoelectric coefficients unnecessary for exciting high-order Lamb waves.

[0091] In Example 1 of the present application, single crystal lithium niobate with Z-cut and in-plane propagation directions of 45° and 225° (Euler angles are (0,0,45°) and (0,0,225°) respectively) As the first piezoelectric film 3 and the second piezoelectric film 4, the normalized thickness (h / λ) of the two piezoelectric films is bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com