Lateral field FBAR structure and thin film transfer manufacturing method thereof

A thin film transfer and lateral field technology, applied in the direction of electrical components, impedance networks, etc., can solve problems such as imperfect processes, quality decline, and equipment that cannot meet the accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

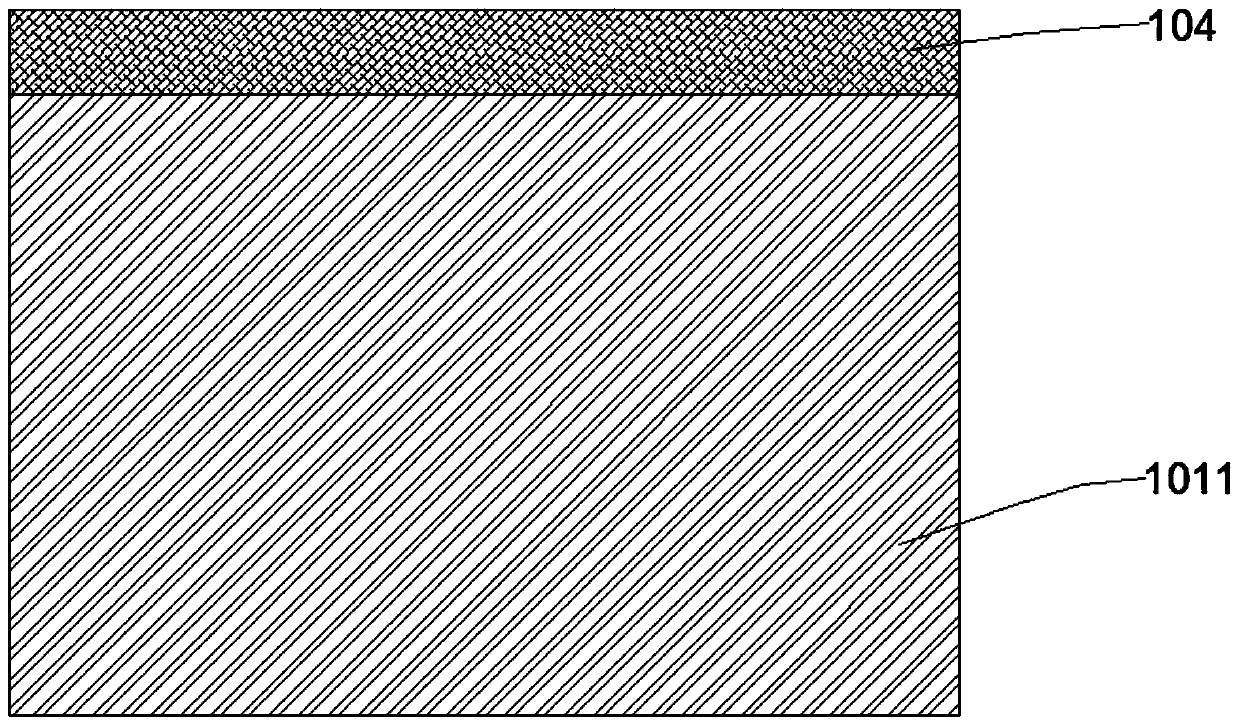

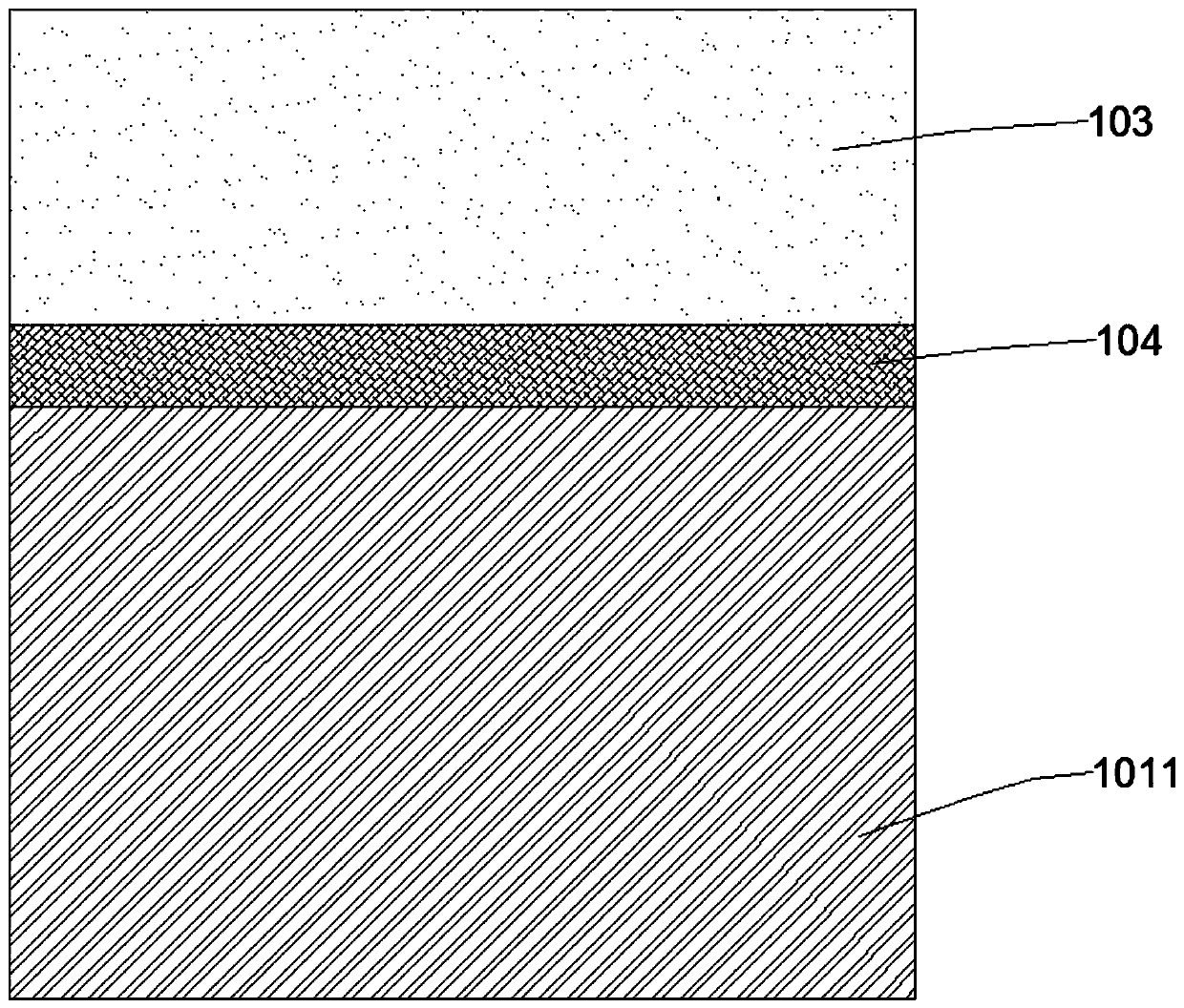

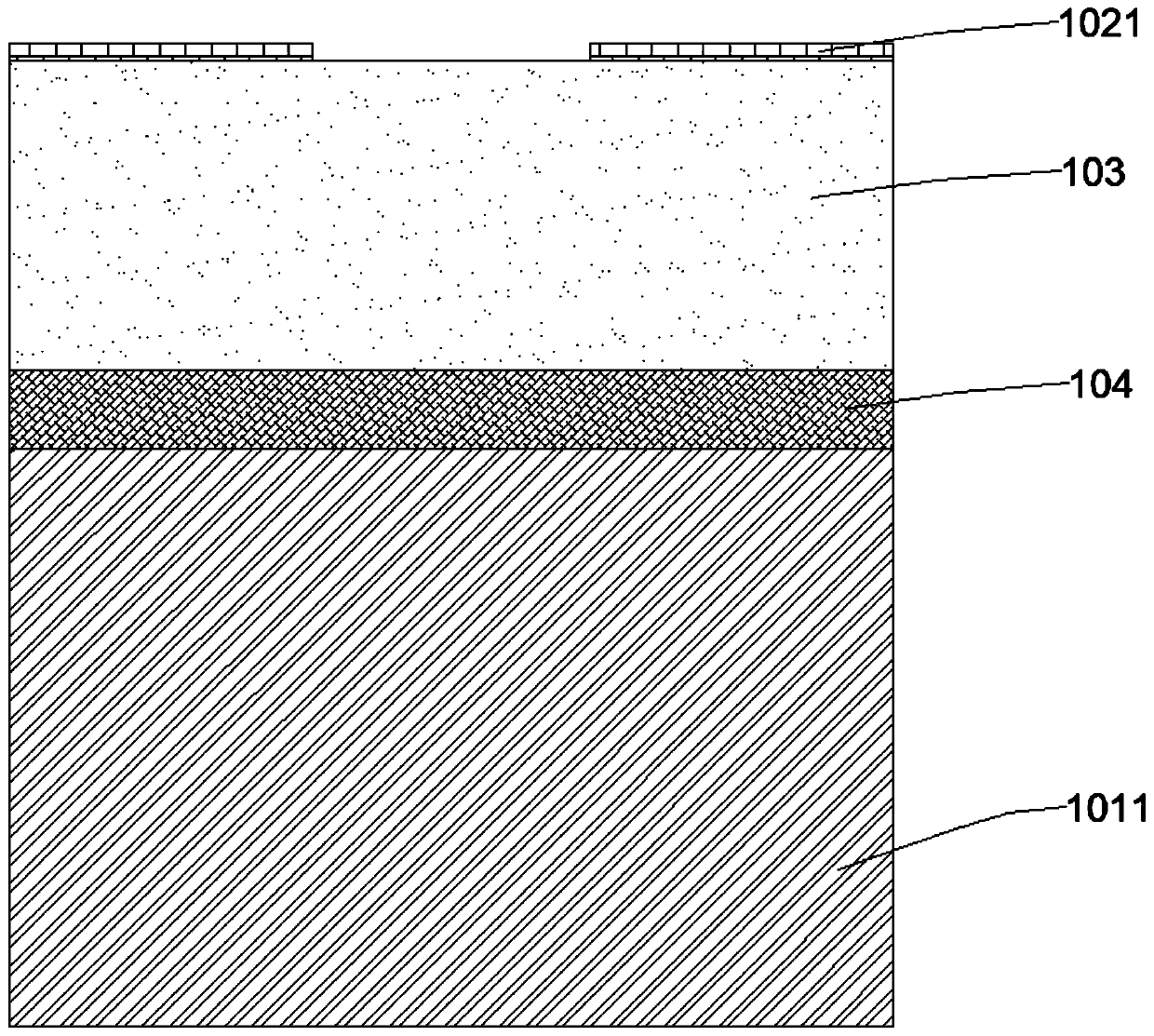

[0095] On the first substrate 1011, positioning marks are set as the substrate for the transfer of the growth film. After the transfer of the film is completed, it needs to be removed. At the same time, there are two silicon substrates, the first substrate 1011 and the second substrate 1012. , so the positioning marks are set accordingly. After the marks are made, the silicon wafer is cleaned, and the first electrode layer 104 of 200nm is grown on the first substrate 1011 by sputtering. The first electrode layer 104 is a Mo electrode layer. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com