Compulsory Disposal of Domestic Cigar Tobacco Leaves

A technology of cigar tobacco leaves and processing methods, which is applied in the direction of processing tobacco, tobacco, and preparing tobacco, etc. It can solve the problems of losing the natural aroma of cigar tobacco leaves, reducing economic value, and not being able to modify them, so as to shorten the time of elimination, reduce irritation, The effect of increasing alcohol and degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

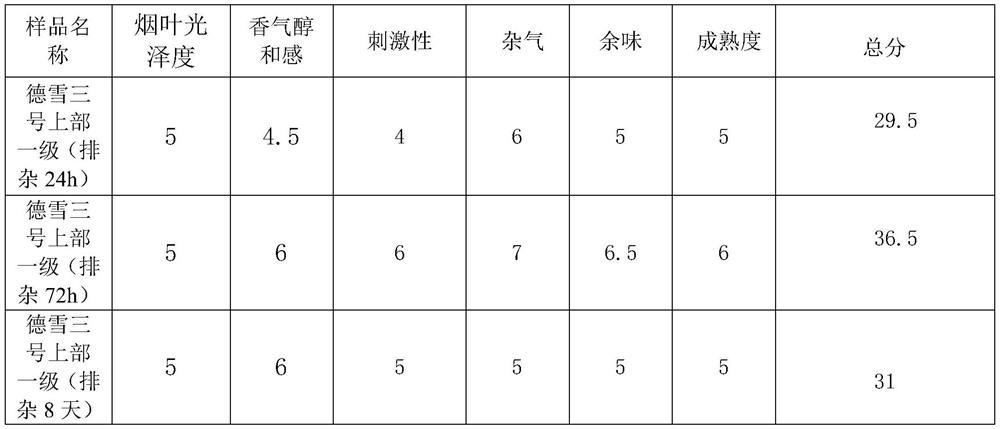

Embodiment 1

[0021] Select the low-quality raw materials that are more irritating, heavier, and have more residue in the mouth from Shifang cigar tobacco leaves in Sichuan, put them into oak barrels, put them in the fermentation room, set the humidity to 75%, and ferment them at 35°C for 35 days; After the barrel fermentation, the cigar raw materials are loosened and laid flat on the wooden frame. The stacking height of the tobacco leaves is 18cm, the temperature of the fermentation room is 48°C, and the humidity is 70%. Check the quality, the time is 3 days. The cigar tobacco leaves after forced impurity removal are placed indoors, and the moisture of the tobacco leaves can reach the moisture required by the process.

Embodiment 2

[0023] Select the low-quality raw materials that are more irritating, heavier, and have more residue in the mouth from Shifang cigar tobacco leaves in Sichuan, put them into oak barrels, put them in the fermentation room, set the humidity to 75%, and ferment them at 35°C for 35 days; After the barrel fermentation, the cigar raw materials are loosened and laid flat on the wooden frame. The stacking height of tobacco leaves is 18cm, the temperature of the fermentation room is 45°C, and the humidity is 65%. Check the quality, the time is 2 days. The cigar tobacco leaves after forced impurity removal are placed indoors, and the moisture of the tobacco leaves can reach the moisture required by the process.

Embodiment 3

[0025] Select the low-quality raw materials that are more irritating, heavier, and have more residue in the mouth from Shifang cigar tobacco leaves in Sichuan, put them into oak barrels, put them in the fermentation room, set the humidity to 75%, and ferment them at 35°C for 35 days; After the barrel fermentation, the cigar raw materials are loosened and laid flat on the wooden frame. The stacking height of the tobacco leaves is 18cm, the temperature of the fermentation room is 50°C, and the humidity is 75%. Check the quality, the time is 2 days. The cigar tobacco leaves after forced impurity removal are placed indoors, and the moisture of the tobacco leaves can reach the moisture required by the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com