Online grinding equipment for cathode roller

A cathode roller and equipment technology, applied in grinding/polishing equipment, grinding machine tools, grinding tools, etc., can solve the problems of low work efficiency, scrapped cathode rollers, affecting production, etc., so as to improve the efficiency of maintenance and realize online grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

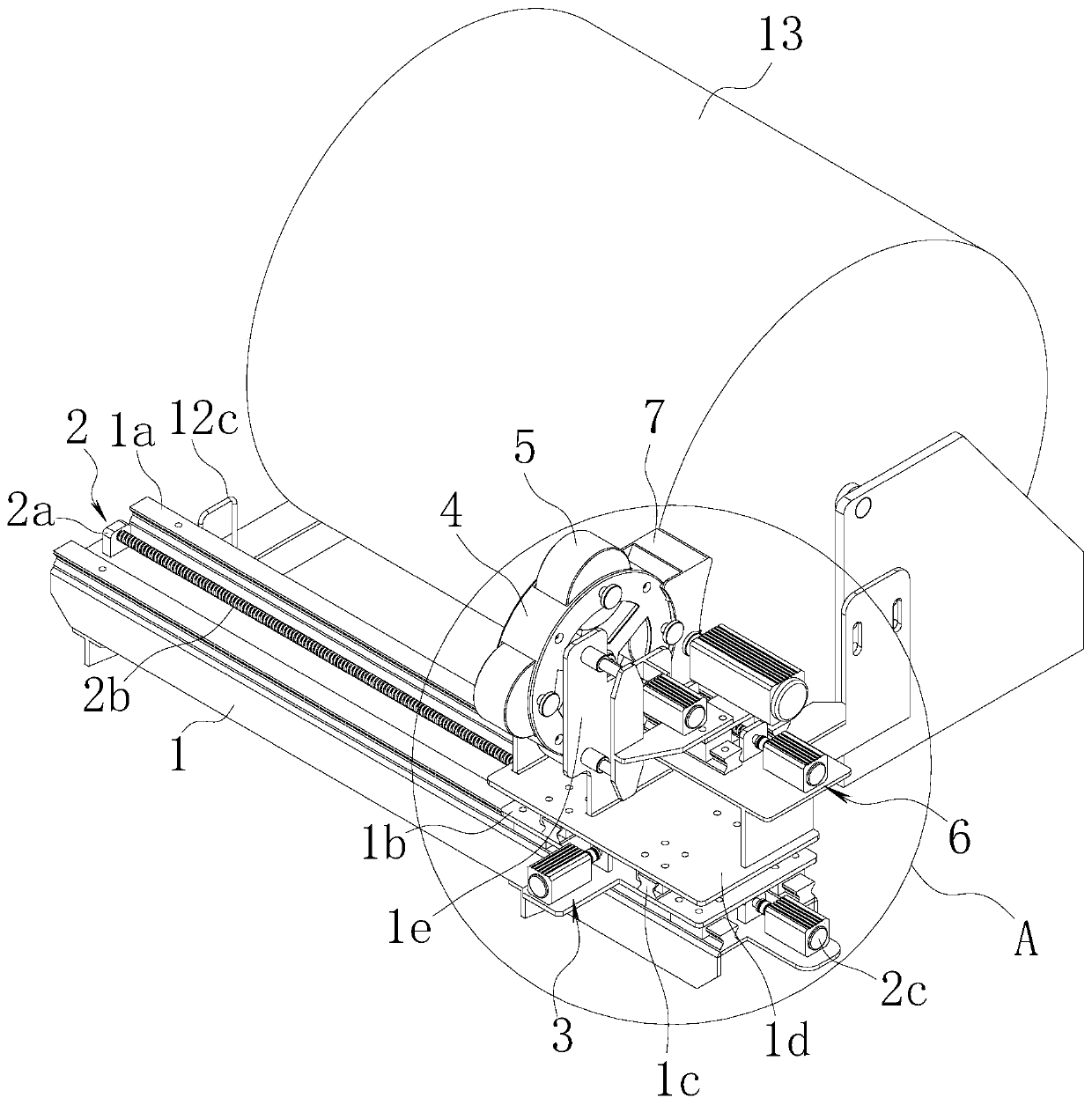

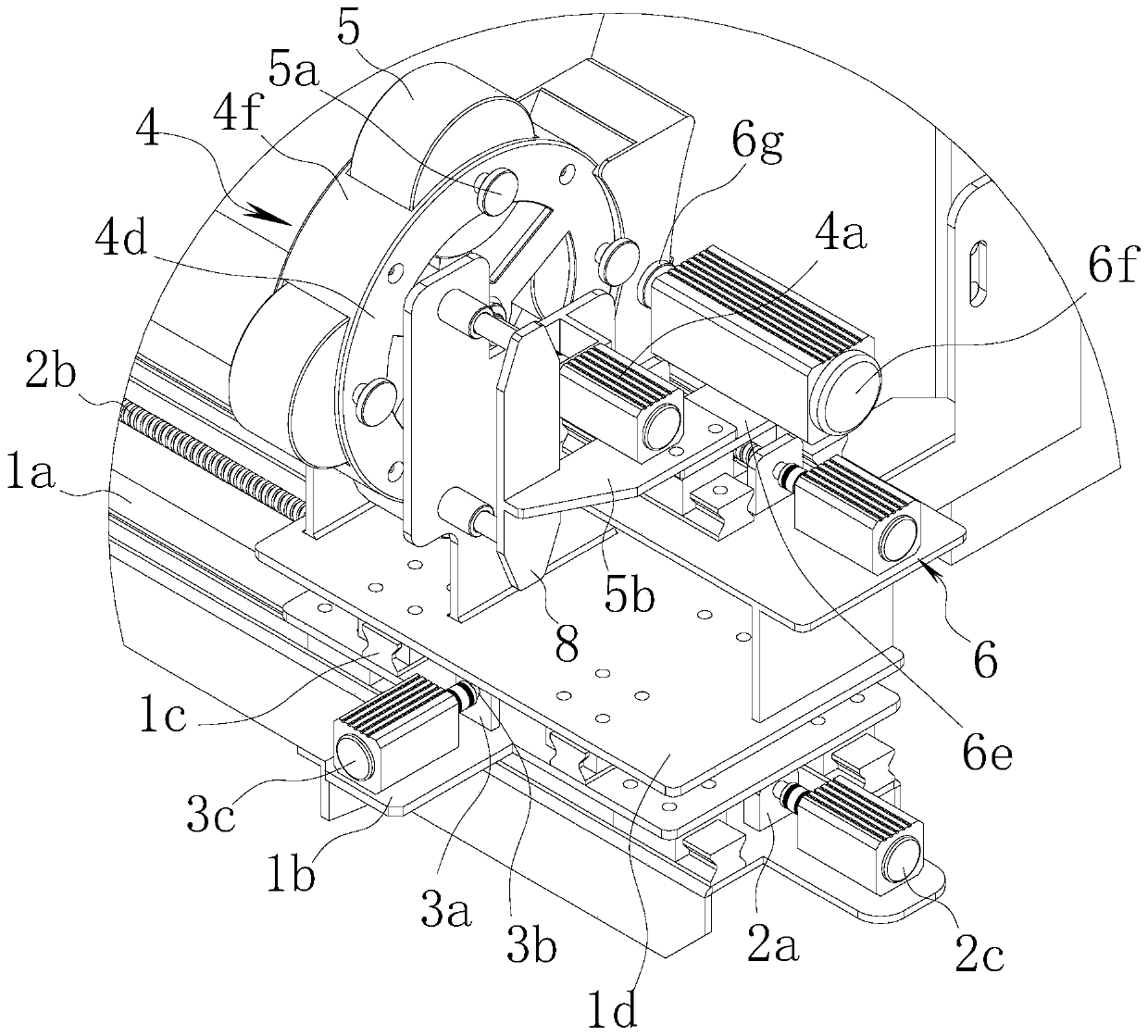

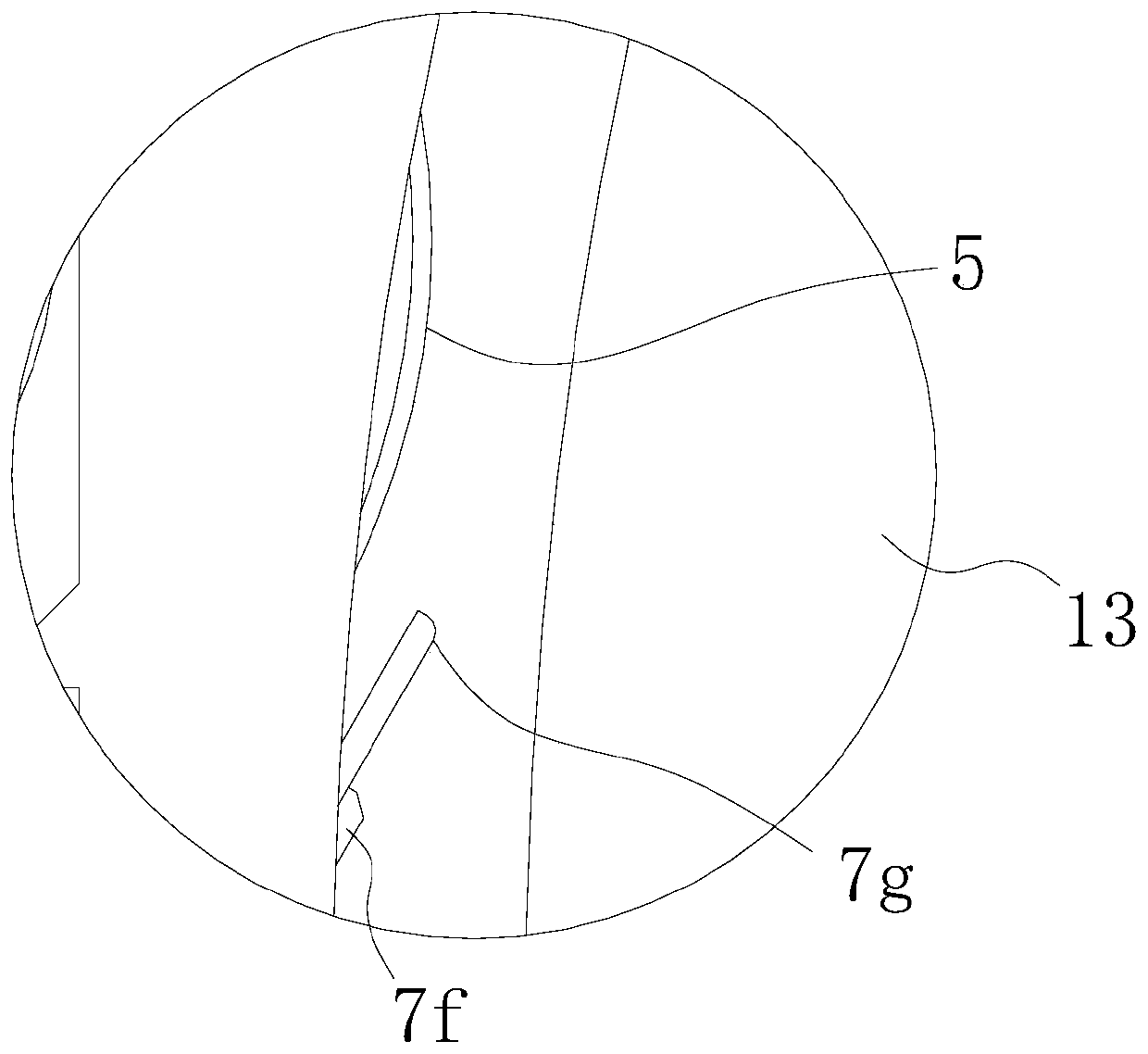

[0037] refer to Figure 1 to Figure 8 As shown, a cathode roll online grinding device of the present invention includes a support 1 fixed on the side of the cathode roll 13, and an axial guide rail 1a is arranged on the support 1 along the axial direction of the cathode roll 13, and on the axial guide rail 1a An axial sliding seat 1b is movable, and the axial sliding seat 1b is connected with an axial displacement driving mechanism 2 . The axial displacement drive mechanism 2 consists of two axial support plates 2a arranged at intervals on the bracket 1, an axial screw rod 2b which is horizontally movable on the axial support plate 2a through bearings, and an axial One end of the screw rod 2b is connected with the second servo motor 2c which is linked.

[0038] A radial guide rail 1c is arranged radially along the cathode roller 13 on the axial slide seat 1b, a radial slide seat 1d is movably arranged on the radial guide rail 1c, and a radial displacement drive mechanism 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com