Slag discharging system applicable to power station boiler

A power plant boiler and slag technology, which is applied in solid separation, filter screen, grid, etc., can solve problems such as jamming and tripping of the slag crusher, non-stop of the unit, and influence on power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

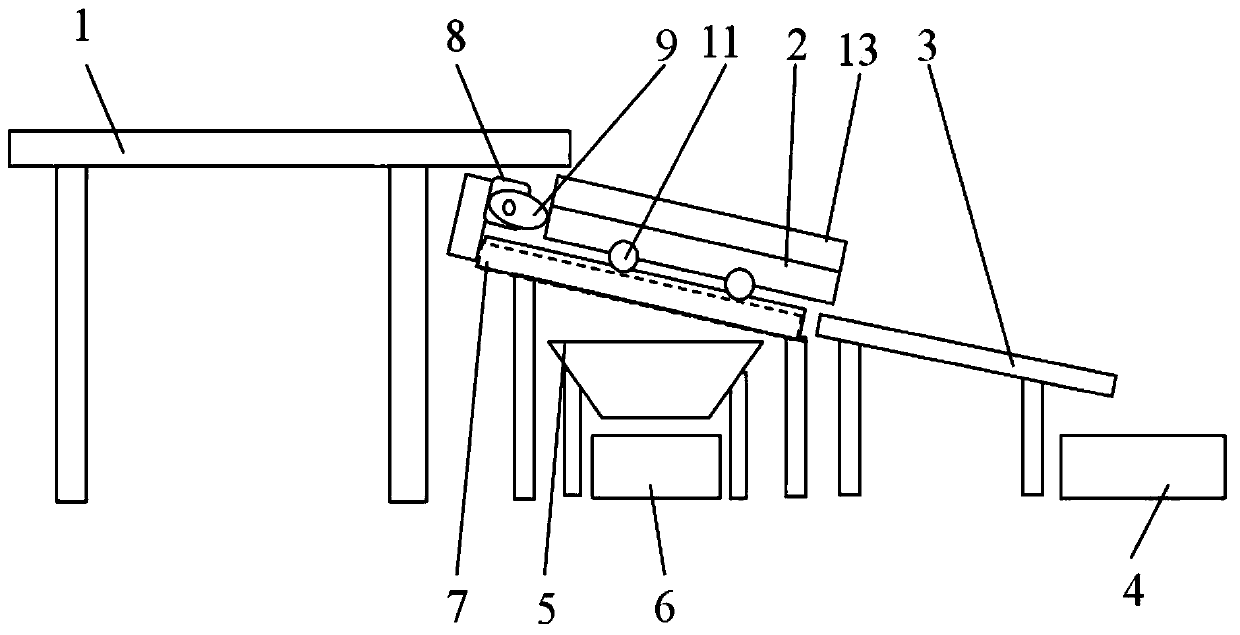

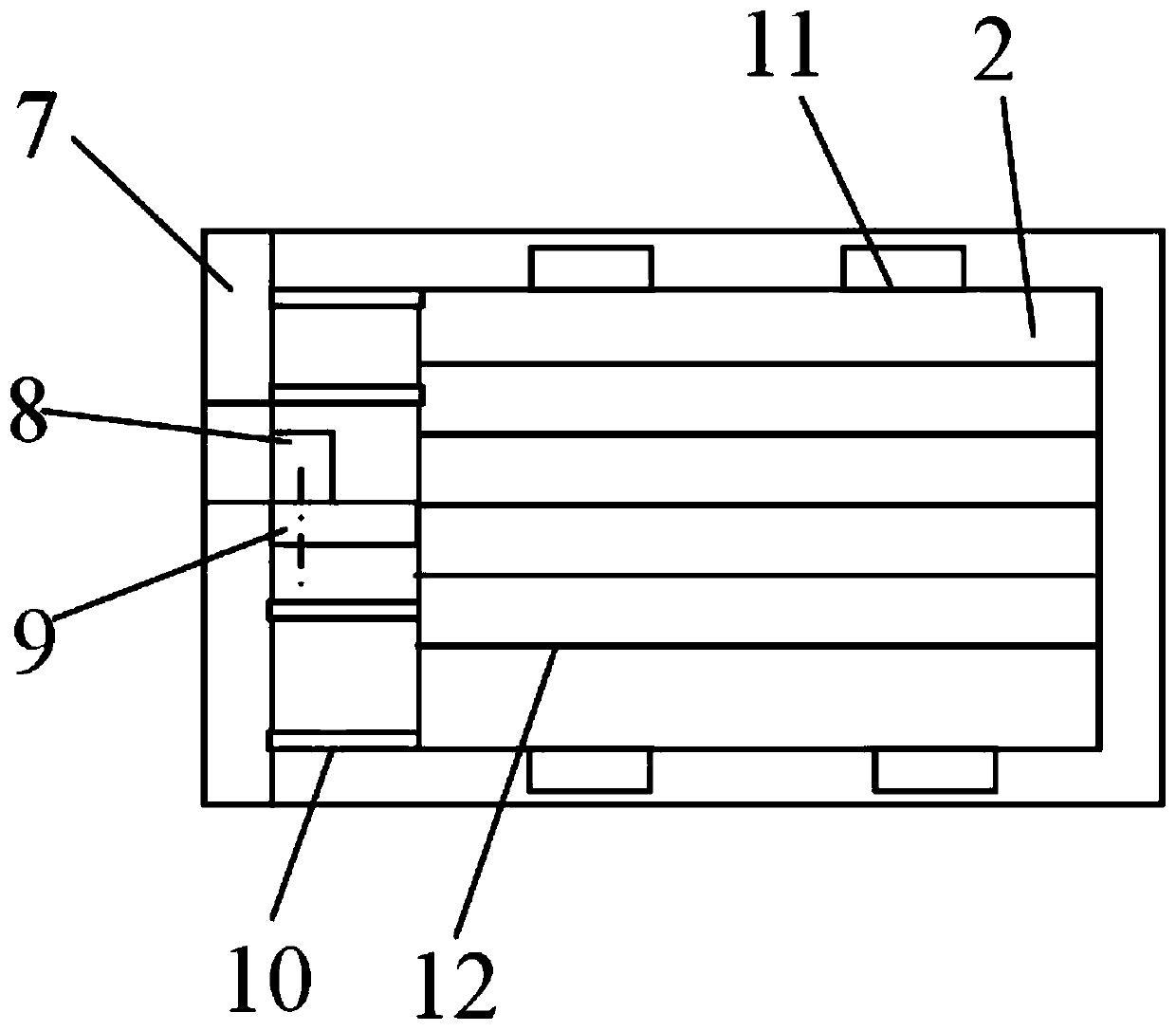

[0017] The present invention is a kind of slagging system suitable for power plant boilers, referring to figure 1 , including a steel belt machine 1, the bottom of the output end of the steel belt machine 1 is provided with a hollow strip groove 2 that can shake back and forth along the slag output direction, and a plurality of parallel steel rollers are fixed at the bottom of the hollow strip groove 2, and the hollow strip groove 2 The input end is higher than the output end, the bottom of the output end of the hollow strip groove 2 is provided with a conveyor belt 3, the bottom of the output end of the conveyor belt 3 is provided with a slag bucket a4, the bottom of the hollow strip groove 2 is equipped with a slag crusher 5, and the slag crusher 5 outputs The bottom of the end is provided with a slag hopper b6.

[0018] The hollow strip g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com