Cooling fin, heating unit and electric radiator

A technology of heat sink and heating body, which is applied in the directions of space heating and ventilation, space heating and ventilation details, household heating, etc. The effect of reducing thermal conductivity and preventing burns to users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

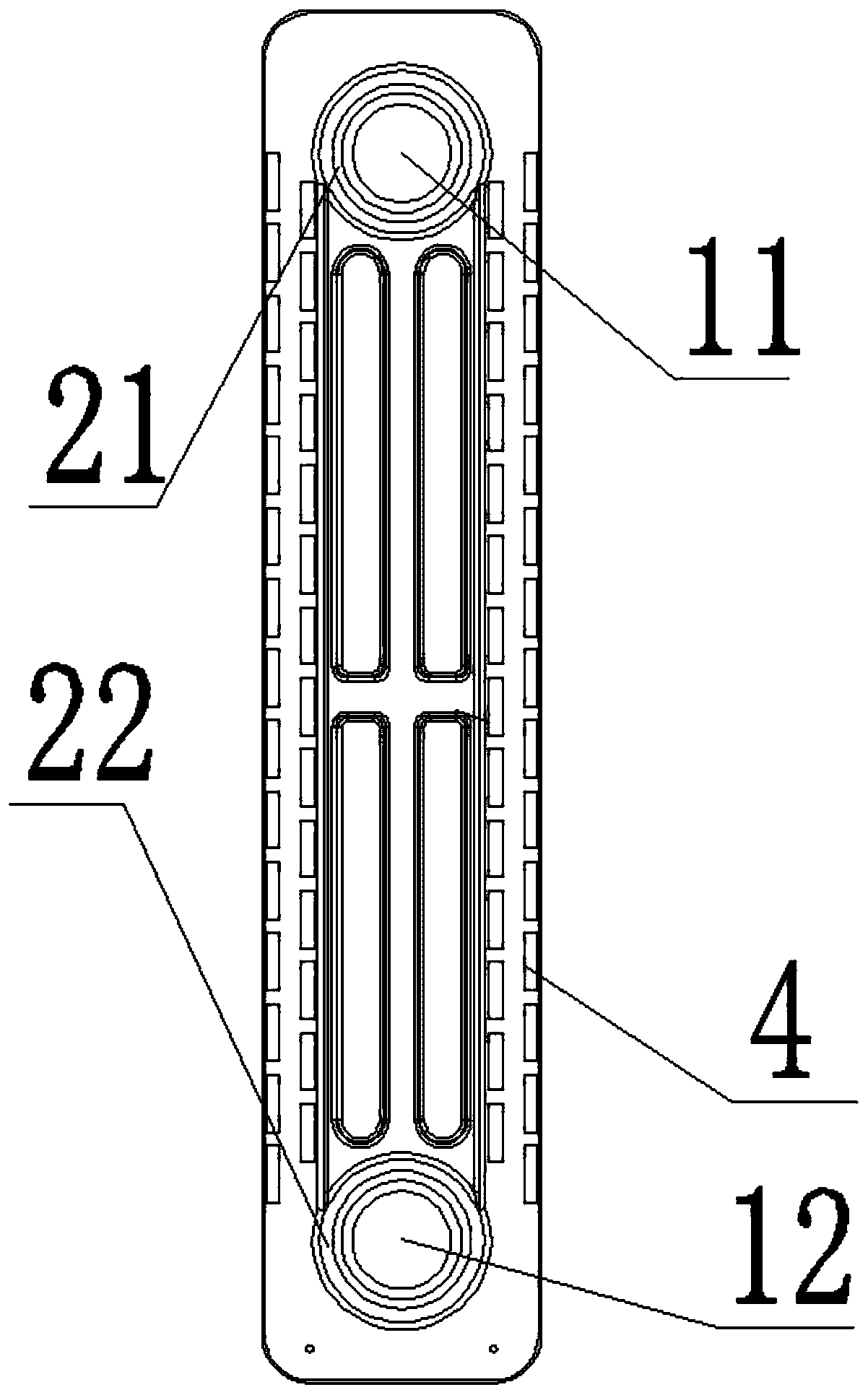

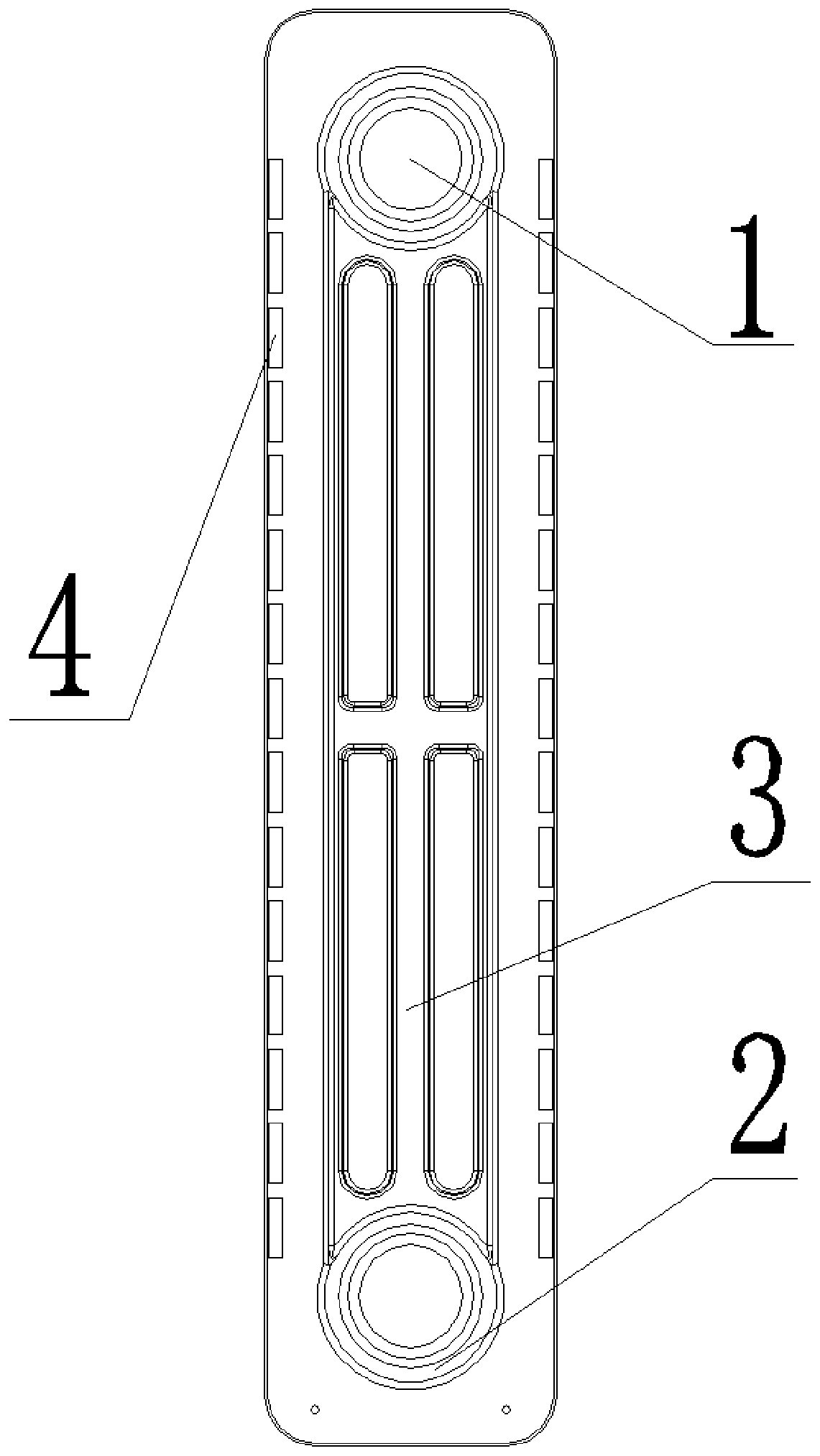

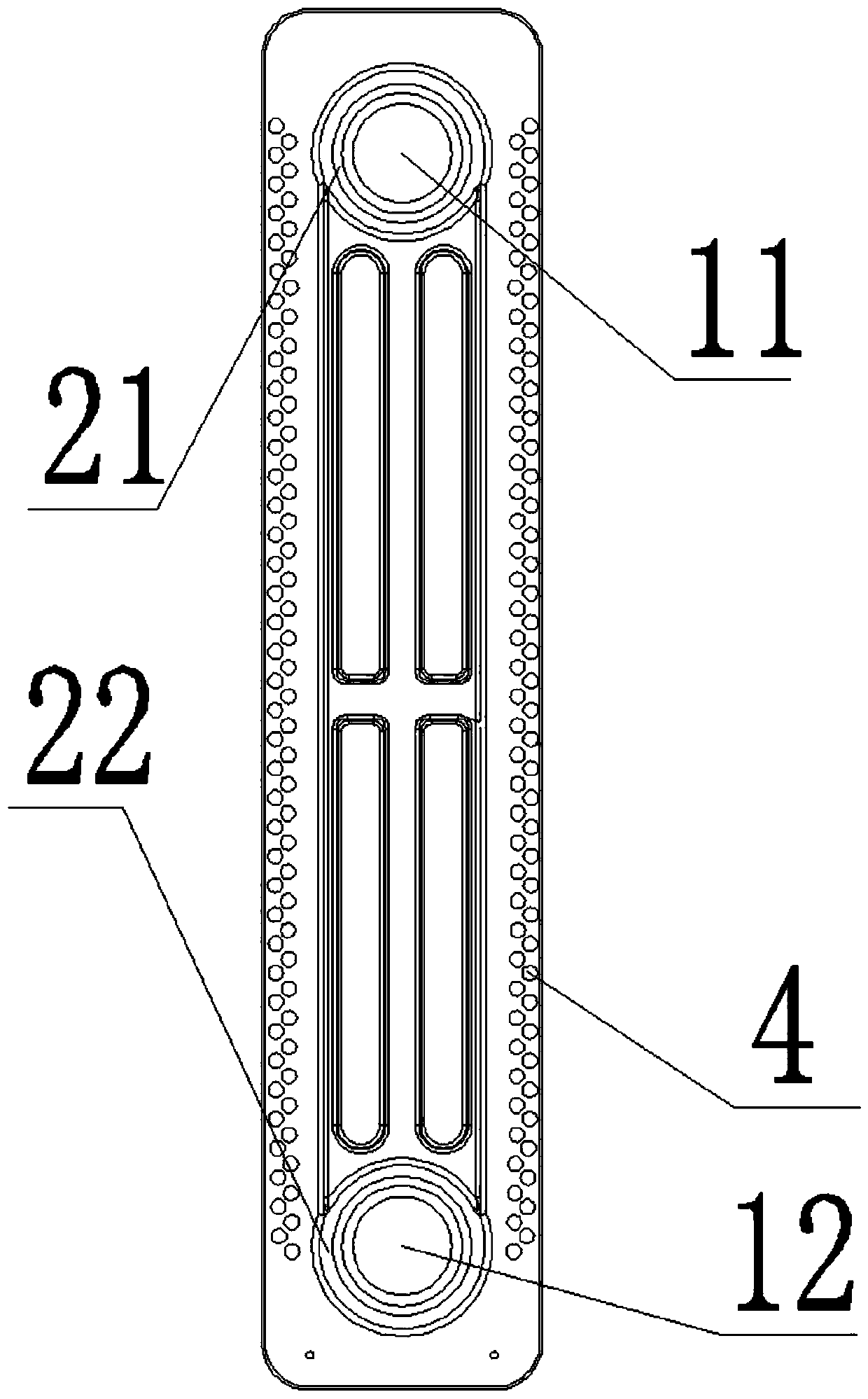

[0039] Such as figure 1 - Figure 4 As shown, the present embodiment provides a heat sink, which includes a heat conduction oil passage 32 , a heat conduction oil passage and a through hole 4 .

[0040] The heat sink is in the shape of a rectangular sheet, each corner is rounded, and includes a cavity 1. The cavity 1 is respectively provided with an upper cavity part 11 and a lower cavity part 12 along the height direction. The lower cavity part 12 is connected with the heating rod. The upper oil bag 21 is arranged on the side of the cavity 11, and the lower oil bag 22 is arranged along the side of the lower cavity 12. And heat-conducting oil is arranged in the heat-conducting oil circuit.

[0041] In this embodiment, the heat conduction oil passages are three-way, arranged along the vertical direction, and the middle parts of the three heat conduction oil passages are connected. As an alternative embodiment, the heat conduction oil passage can be arranged in a curved cross...

Embodiment 2

[0049] This embodiment provides a heating element, including the heat sink and the heating rod provided in Embodiment 1. Several above-mentioned cooling fins are arranged side by side with each other, and the heating rod is penetrated at the position of the hole-shaped lower cavity 12 of each cooling fin at the same time, for heating the lower oil bag 22 .

Embodiment 3

[0051] This embodiment provides an electric heater, including the heating element, temperature control element, indicator light, auxiliary device and other structures provided in Embodiment 2. Both the temperature control element and the indicator light are arranged on the heating body, and the indicator light is electrically connected with the temperature control element.

[0052] The auxiliary device includes but is not limited to: a clothes hanger, which is arranged above the heating element, and is suitable for drying clothes, etc.; it can also be a mobile bracket, which is arranged at the bottom of the heating element, and is used to support the heating element or drive the heating element. body to move. The mobile bracket itself can be a folding structure or an integrally formed structure. When the folding structure is adopted, it is convenient to reduce the space occupation when it is idle and improve the storage efficiency of the electric heater.

[0053] The electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com