Low-cycle fatigue life prediction method considering microstructure influence

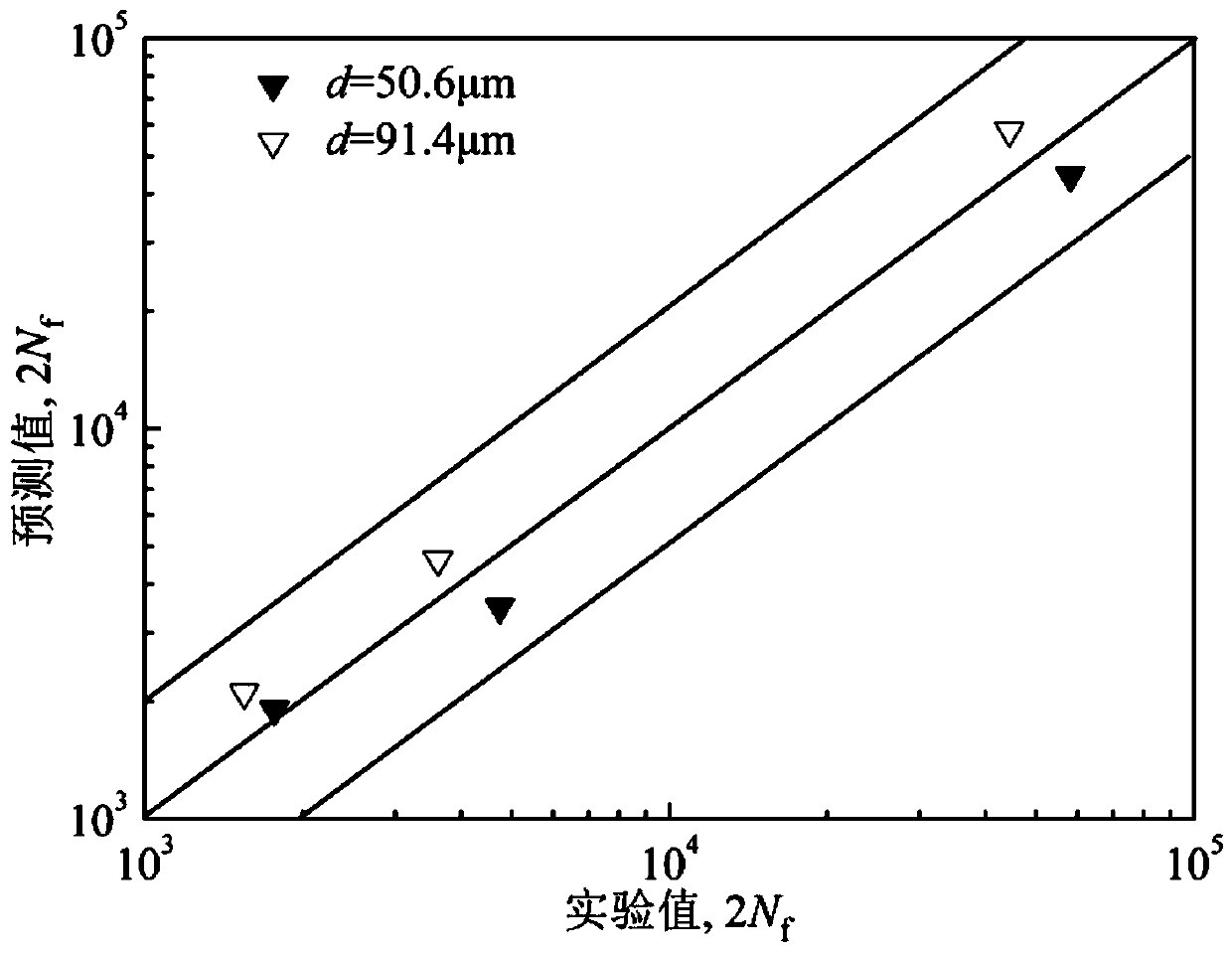

A low-cycle fatigue, microstructure technology, applied in instrumentation, computer material science, design optimization/simulation, etc., can solve the problem of not establishing the quantitative relationship between fatigue life and microstructure, and achieve uniform error distribution, universal applicability, prediction high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Such as figure 1 As shown, the present invention provides a low-cycle fatigue life prediction method considering the influence of microstructure.

[0035] Experimental material: Inconel 718 nickel-based superalloy, a commonly used material for key hot-end components such as aero-engine combustors, turbine disks, blades and guide vanes, is selected. The composition of the alloy is Ni 52.80, Cr 18.73, Nb 5.24, Mo3.02, Al 0.52 , Ti 0.95, C 0.026, Co 0.03, Fe balance.

[0036] Inconel 718 nickel-based superalloy was machined into six standard low-cycle fatigue samples, which were divided into two groups.

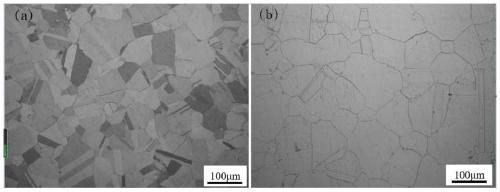

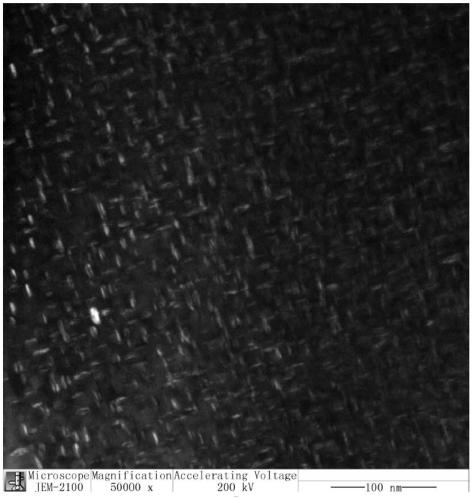

[0037] Two groups of low-cycle fatigue samples of Inconel 718 nickel-based superalloy were subjected to different vacuum high-temperature solution treatment and aging treatment systems to obtain different average grain sizes of matrix phases and equivalent precipitation phases (γ′, γ″). The radius and volume fraction are respectively marked as heat treatment system I an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com