Pickling method for profiles, rolled strips, and sheets made of aluminium alloys

A technology of aluminum alloy and aluminum alloy products, applied in the direction of metal material coating process, coating, surface reaction electrolytic coating, etc., to improve corrosion resistance, small loss, phosphatability and adhesive adhesion. Sexual improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

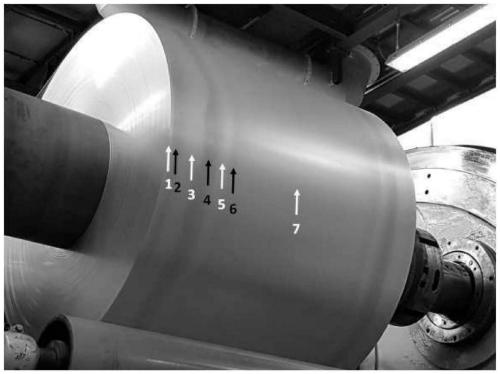

[0058] figure 1 The aluminum alloy strip shown has a high magnesium content and corresponds to a composition according to AA5182. The defect already described here is shown at the edge in the form of irregular, wavy gray-brown streaks. The strip was first etched alkaline (0.5% NaOH, 1.5% degreaser composition consisting of nonionic and anionic surfactants and complexing agents; contact time 45 seconds) and then acid etched (2% HNO 3 +300ppm F - ; contact time 11 seconds). figure 2 The strips shown in are made with figure 1 The strips in the same batch are manufactured. figure 2 strips were additionally subjected to an acidic pre-cleaning according to the invention (2% HNO 3 +300ppm F - ; contact time 11 seconds). Defects were not visually recognizable on this tape.

[0059] In laboratory tests, aluminum alloy strips were compared which, on the one hand, were treated according to the three-step corrosion method according to the invention (samples CV2, CV3, CV5), and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com