Cake quick cutting device

A technology for cake and slicing, which is applied in the division/slicing, baking, and processing of baked food, etc., which can solve the problem of uneven cutting and achieve the effect of reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

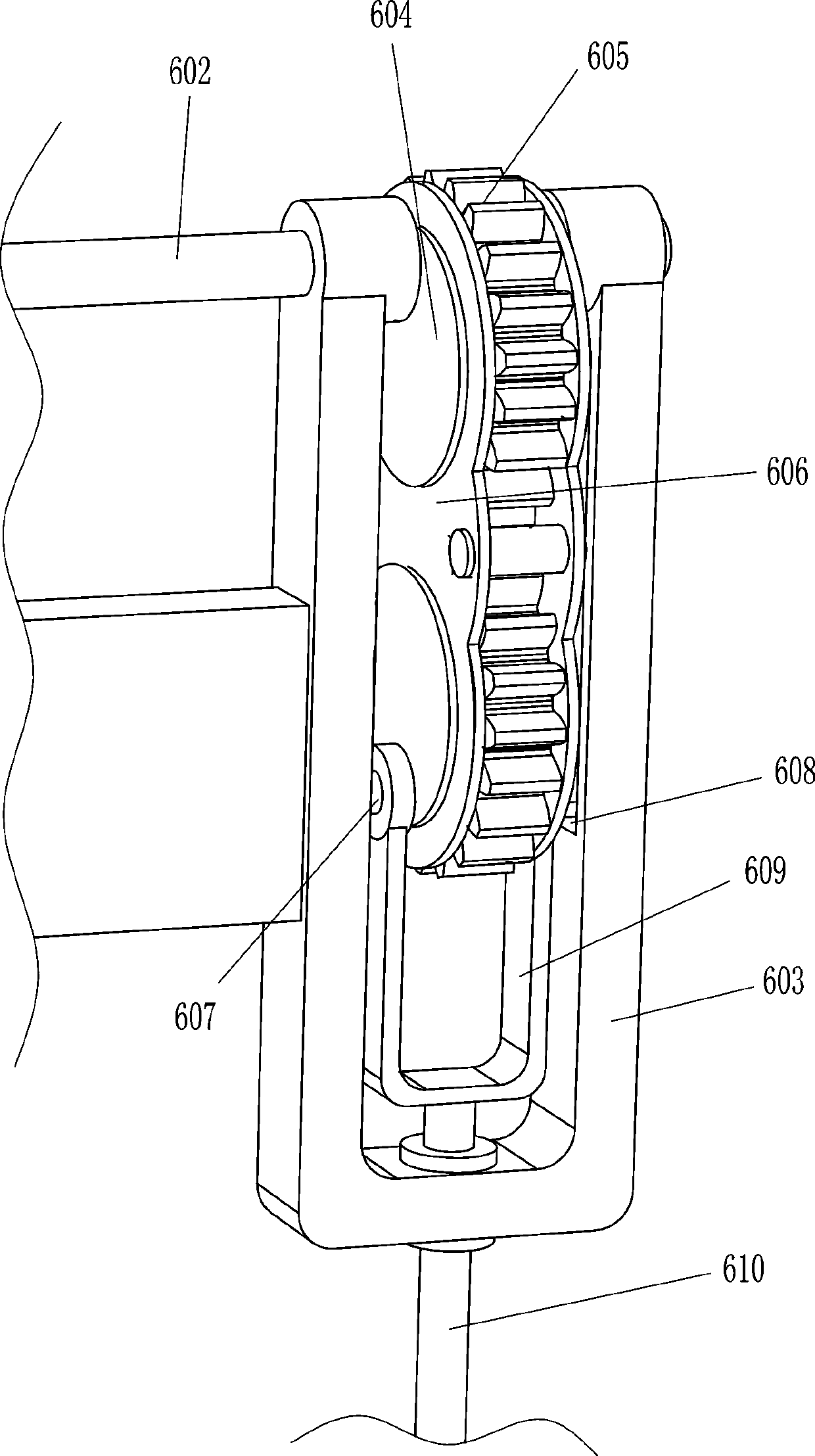

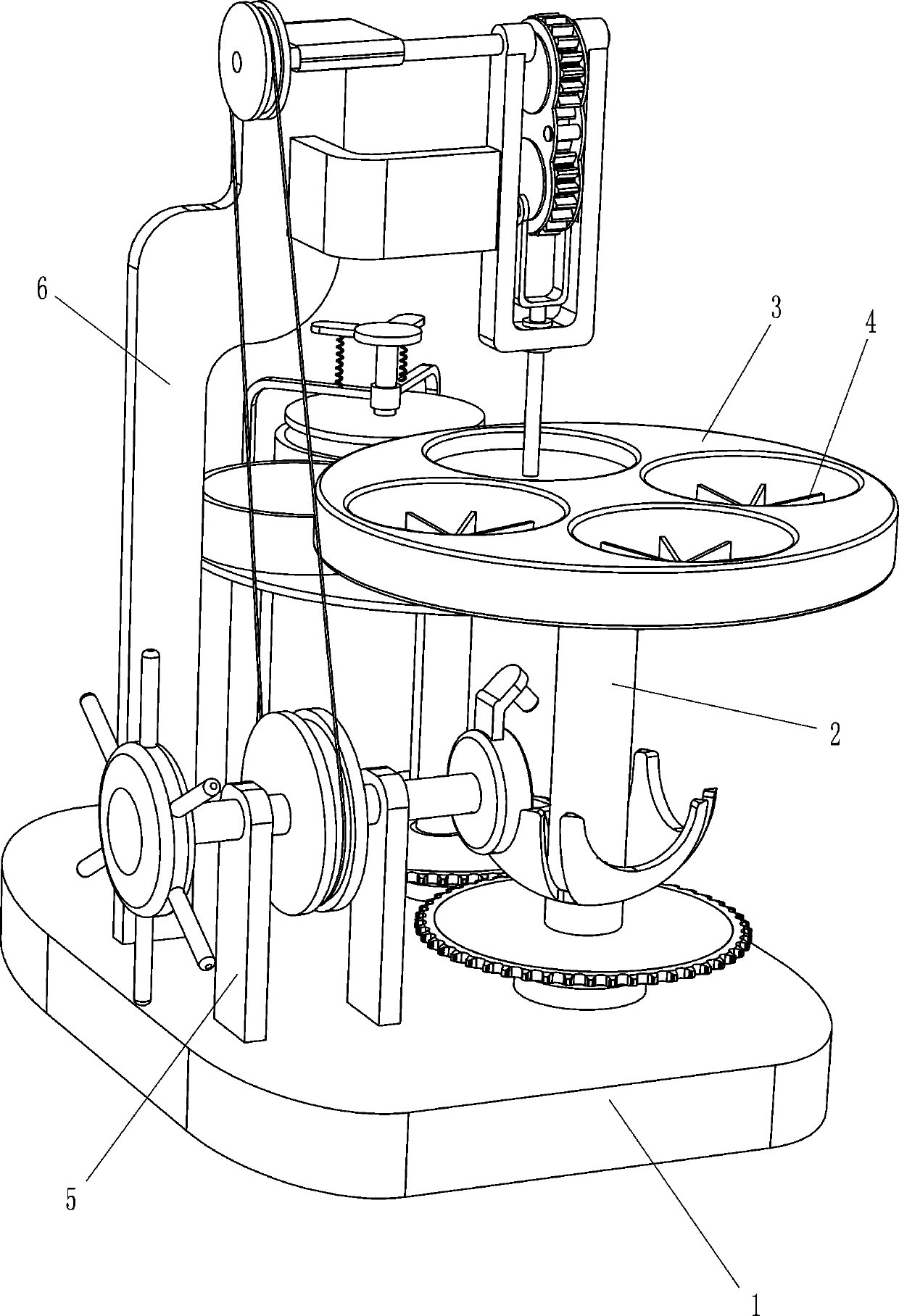

[0036] A quick cake cutting equipment, such as figure 1 As shown, it includes a base plate 1, a first rotating shaft 2, a turntable 3, a cutter 4, a rotating mechanism 5, and a pressing mechanism 6. The right front side of the bottom plate 1 is rotatably installed with the first rotating shaft 2, and the top of the first rotating shaft 2 is provided with a turntable. 3. Four grooves are uniformly arranged on the turntable 3, and the cutter 4 is evenly installed in the grooves. The front side of the base plate 1 is provided with a rotating mechanism 5, which is connected to the first rotating shaft 2. The left side of the base plate 1 is equipped with a lower Press mechanism 6.

[0037] When the cake needs to be cut into pieces, four cakes are first placed on the cutting knife 4, and then the parts in the rotating mechanism 5 are manually rotated clockwise, and the parts of the rotating mechanism 5 rotate clockwise thereupon. Under the action, the first rotating shaft 2 rotate...

Embodiment 2

[0039] On the basis of embodiment 1, with reference to Figure 1-4 As shown, the rotating mechanism 5 includes a fixed plate 51, a second rotating shaft 52, a handle 53, a toggle block 54 and an arc plate 55, and two fixed plates 51 are vertically arranged on the front side of the left part of the base plate 1, and the two fixed plates The second rotating shaft 52 is rotatably installed between the 51 upper parts, the left end of the second rotating shaft 52 is connected with a turning handle 53, the right side of the second rotating shaft 52 is equipped with a toggle block 54, and the bottom of the first rotating shaft 2 is provided with an arc-shaped plate 55. Shaped plate 55 cooperates with toggle block 54.

[0040]First put the cake on the cutter 4, then manually turn the handle 53 clockwise, the handle 53 drives the second rotating shaft 52 to rotate clockwise, the second rotating shaft 52 drives the toggle block 54 to rotate, at the same time, the second rotating shaft 5...

Embodiment 3

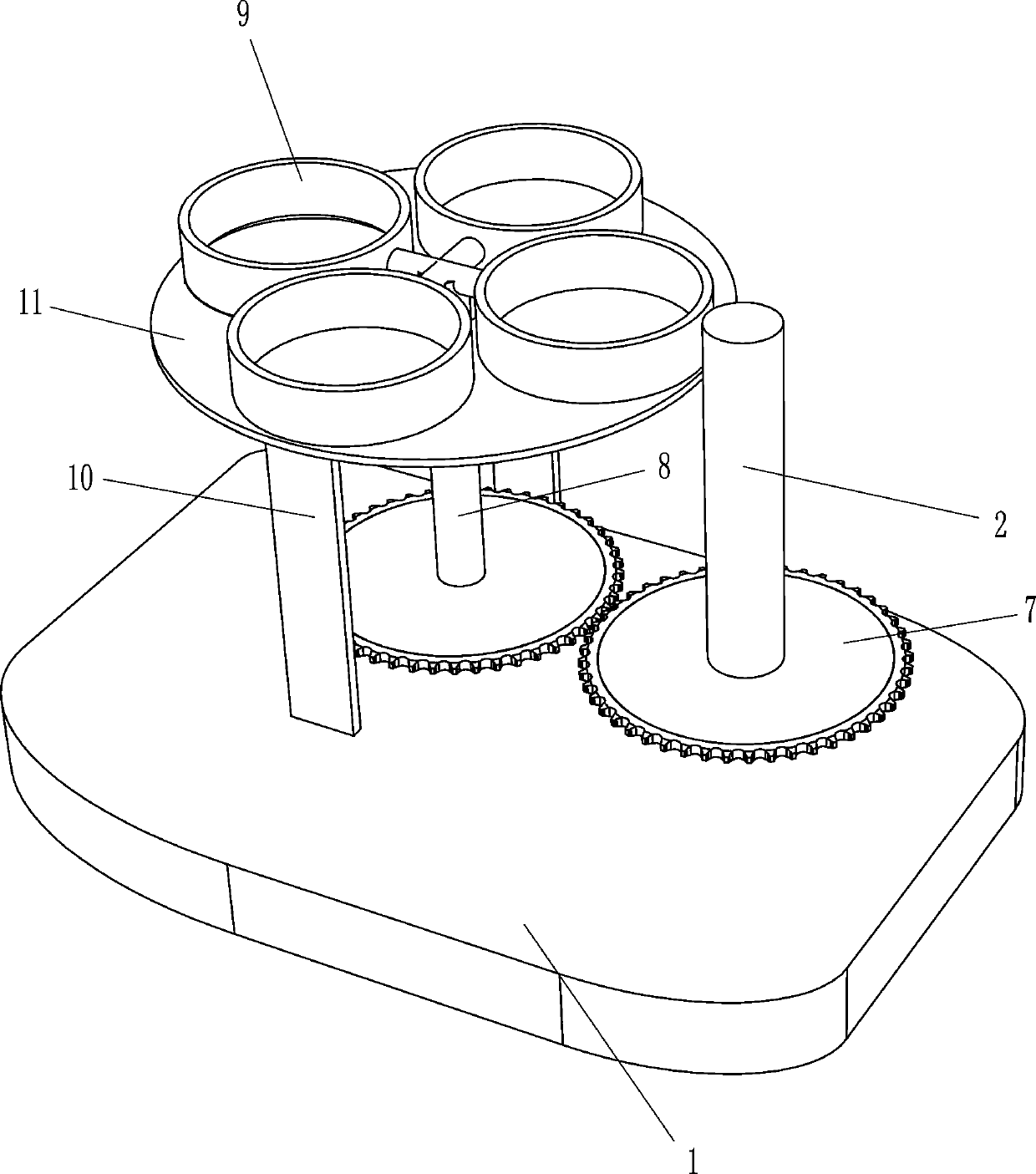

[0044] On the basis of Example 2, such as Figure 5-6 Shown, also comprise big gear 7, the 4th rotating shaft 8, installation frame 9, mounting plate 10 and big circular plate 11, bottom plate 1 right side rear part rotation type is provided with the 4th rotating shaft 8, the 4th rotating shaft 8 and the first rotating shaft 2 The lower part is connected with a large gear 7, and the two large gears 7 are meshed. The large gear 7 is located below the arc plate 55, and the left and right sides of the rear of the bottom plate 1 are vertically provided with mounting plates 10, and the tops of the mounting plates 10 on both sides A large circular plate 11 is connected between them, the upper part of the fourth rotating shaft 8 passes through the center of the large circular plate 11, and four mounting frames 9 are arranged on the top of the fourth rotating shaft 8, and the mounting frames 9 are uniformly located on the large circular plate 11.

[0045] When the pressing plate 611 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com