Intelligent welding precision workstation for mine belt feeder bracket longitudinal beam

A feeder and workstation technology, applied in the field of intelligent welding precision workstations, can solve the problems of poor interchangeability of bracket longitudinal beams, high labor intensity, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

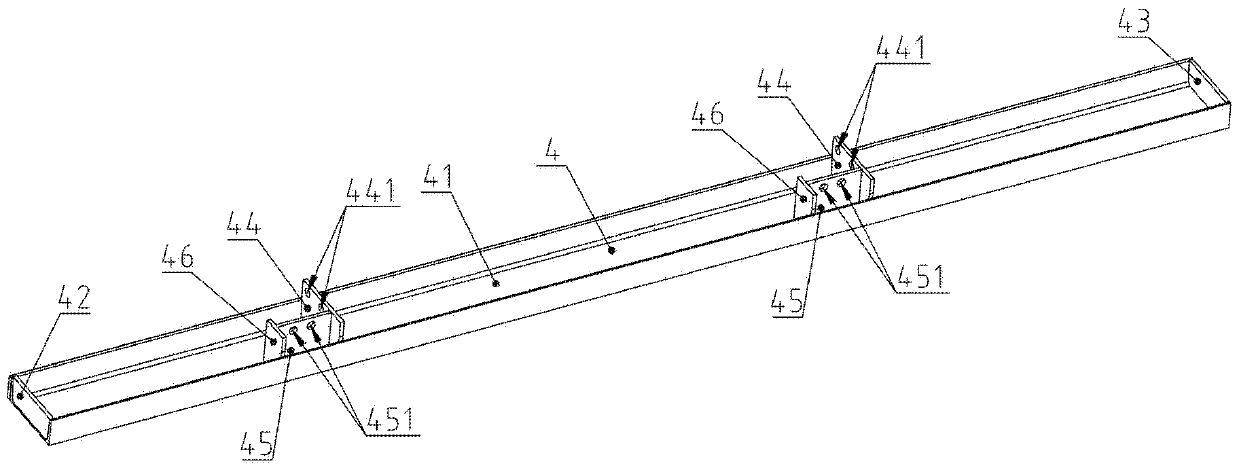

[0059] Example: see Figure 1 to Figure 15 .

[0060]An intelligent welding precision workstation for the longitudinal beam of a belt feeder bracket in a mine, including a welding robot, a base 1, a servo motor 2, and an overturning assembly 3; the overturning assembly 3 includes an overturning plate assembly 31; the overturning plate assembly 31 includes an overturning plate 311 The turnover plate 311 is provided with an upward turnover panel surface 3111 and a downward turnover panel lower surface 3112; the front end of the turnover panel 311 is provided with a turnover panel front shaft 3181, and the rear end of the turnover panel 311 is provided with a turnover panel rear shaft 3182, The axis line of the front rotating shaft 3181 of the flipping plate coincides with the axis line of the rear rotating shaft 3182 of the flipping plate and is arranged along the front and rear horizontal directions; The shell flange of the housing is fixedly connected with the base 1; the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com