Drill and knife grinding device

A tool sharpening device and drill grinding technology, which is applied in the direction of grinding drive devices, grinding machines, drilling tool accessories, etc., can solve the problems of poor drill bit and tool effect, high cost and complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

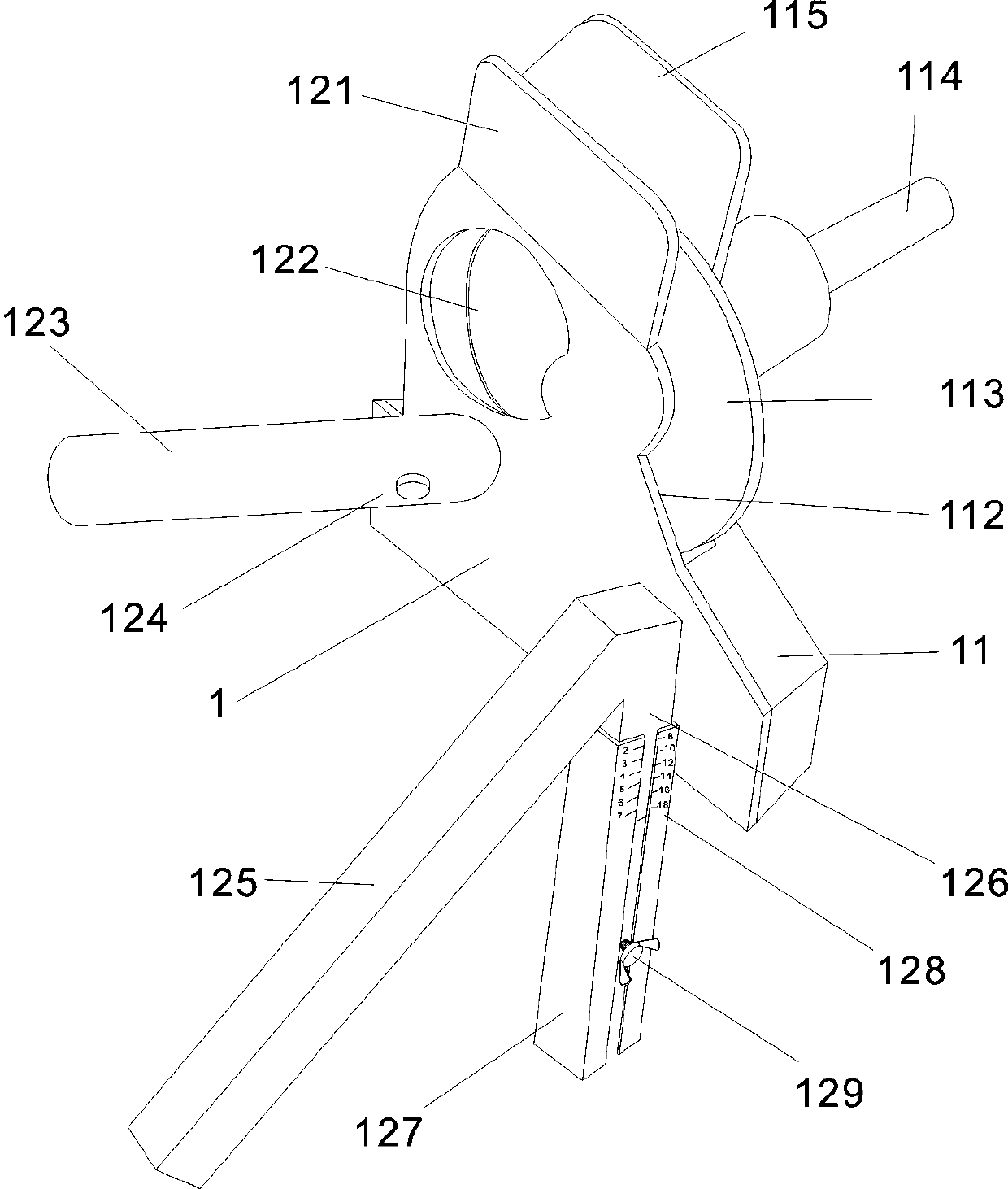

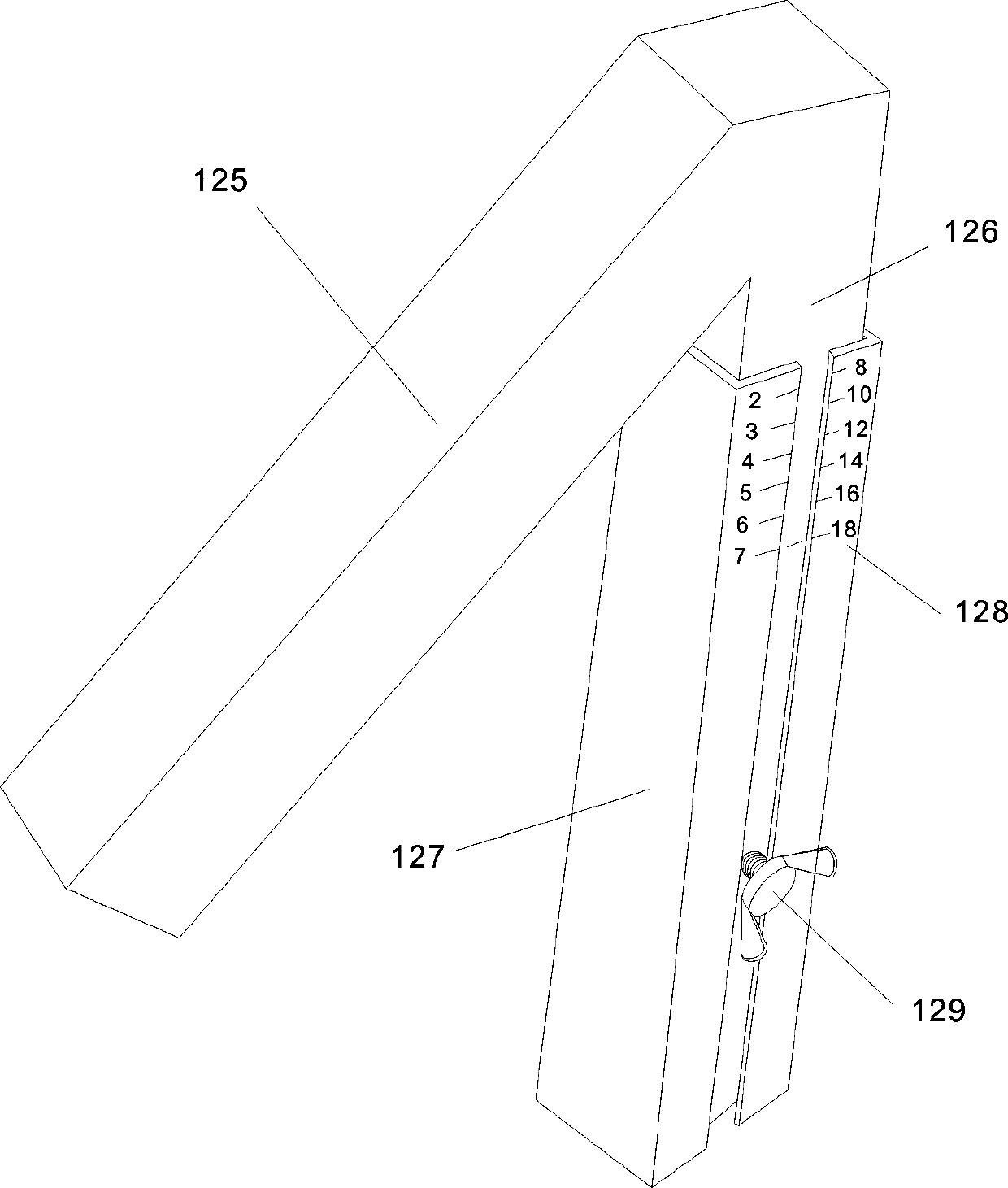

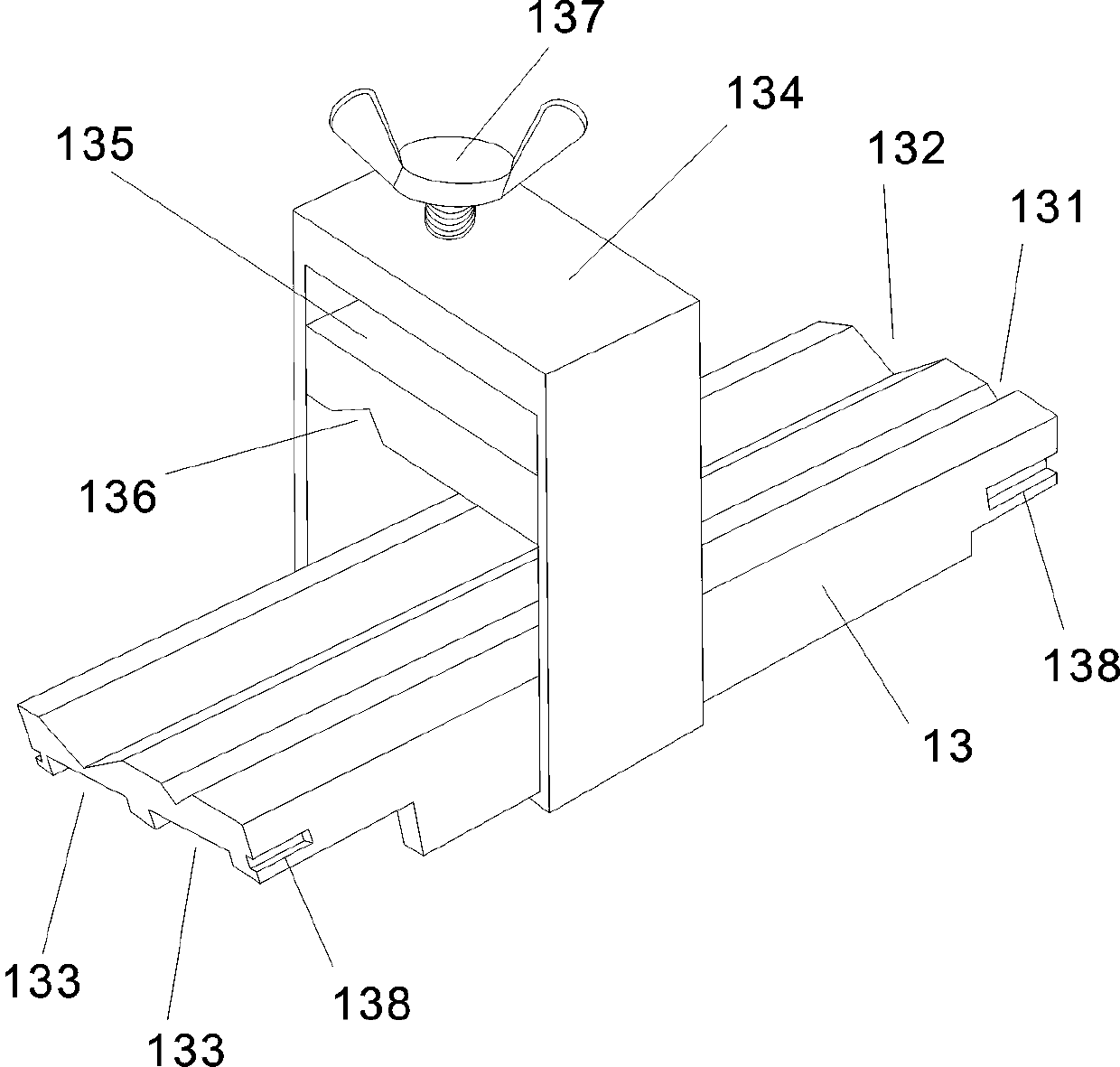

[0014] A kind of drill and knife sharpening device The drill and knife sharpening device 1, the angle grinding sleeve rod 123, the inner angle grinding sleeve rod 125, the outer cover 112, the drill bit sleeve 13, the clamping block 134, the inner angle grinding lifting tube 127 , the top of angle block 14, motor transmission rod 114, emery wheel 113, outer cover 112 is provided with right sharpening bevel 121, and the left upper left of support 11 is provided with left sharpening bevel 115, and the left side of outer cover 112 is also provided with Hole 122.

[0015] The upper left side of the machine base 11 is provided with a left sharpening bevel 115 and a grinding wheel 113 to form a V-shaped opening. When the knife is sharpened, it can be pulled through and sharpened. There is an opening in the middle with bearings on both sides for the insertion of the motor transmission rod 114. 1. One end of the motor transmission rod 114 is equipped with a grinding wheel 113, and one...

Embodiment 2

[0019] The double grinding wheel device 2, the double grinding wheel base 22, the angle grinding sleeve rod 123, the inner angle grinding sleeve rod 125, the outer cover 112, the drill bit sleeve 13, the clamping block 134, the inner angle grinding device Lifting pipe 127, opposite angle block 14, motor transmission rod 114, back cover 225, left gear 223, right gear 224, left emery wheel 223, right emery wheel 224, the top of described outer cover 112 is provided with right grinder bevel 121, The upper left of the double grinder base 22 is provided with a left sharpening bevel 115 .

[0020] The left grinding wheel 223 is set on the upper left of the double grinding wheel base 22, and the right grinding wheel 224 is arranged on the upper right to form a counter-grinding drill angle 244. The inner angle lifting pipe 127 of the grinding wheel is arranged in the middle of the double grinding wheel base 22, and the angle grinding cover rod 123 is connected thereto. Said double gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com