Low-temperature instant salt-resistant integrated water-based thickening agent for fracturing fluid and preparation method of thickening agent

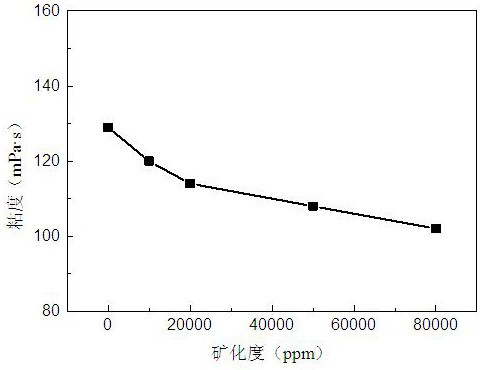

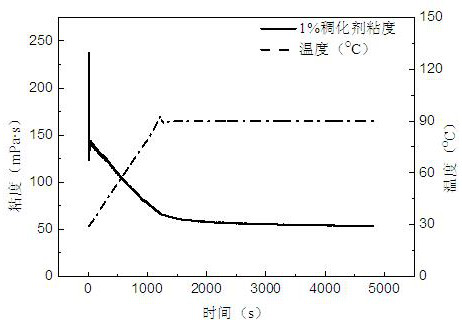

A technology of thickening agent and fracturing fluid, which is applied in chemical instruments and methods, chemical industry, climate sustainability, etc. It can solve the problems of poor salt resistance, polluted formations, slow dissolution, etc., and achieves low cost and low formation pollution. Low, fast dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of low-temperature instant salt-resistant integrated water-based thickener for fracturing fluid

[0033] (1) By adding an appropriate amount of distilled water, the total mass of the monomer is controlled at 17.5% AM, 7.5% AA, 3% ODAAC and 1% SMA hydrophobic functional monomer, 16% AMPS salt-tolerant monomer, 0.2% chelating agent EDTA , the total mass of the reaction system is 1000 g, and the solution is dissolved by magnetic stirring;

[0034] (2) Use 30% NaOH solution to adjust the pH of the system to 6.5;

[0035] (3) Lower the temperature in an ice-water bath, and when the system temperature drops to 2°C, add the monomer solution into a thermos;

[0036] (4) After passing the nitrogen for 40 minutes, add the initiator in an amount of 0.078% (calculated based on the total mass of the monomer) m((NH 4 ) 2 S 2 o 8 ):m(NaHSO 3 ):m(Vc):m(V 50 )=9:4:5:2, when the solution became viscous, the nitrogen flow was stopped, and after standing for 5 h, a white...

Embodiment 2

[0041] Preparation of low-temperature instant salt-resistant integrated water-based thickener for fracturing fluid

[0042] (1) By adding an appropriate amount of distilled water, the total mass of the monomer is controlled at 17.5% AM, 7.5% AA, 3% ODAAC and 1.5% SMA hydrophobic functional monomer, 25% AMPS salt-tolerant monomer, 0.2% chelating agent EDTA , the total mass of the reaction system is 1000g, and the solution is dissolved by magnetic stirring;

[0043] (2) Use 30% NaOH solution to adjust the pH of the system to 6.5;

[0044] (3) Lower the temperature in an ice-water bath, and when the system temperature drops to 2°C, add the monomer solution into a thermos;

[0045] (4) After passing the nitrogen for 40 minutes, add the initiator in an amount of 0.078% (calculated based on the total mass of the monomer) m((NH 4 ) 2 S 2 o 8 ):m(NaHSO 3 ):m(Vc):m(V 50 )=9:4:5:2, when the solution became viscous, the nitrogen flow was stopped, and after standing for 5 h, a whit...

Embodiment 3

[0054] Preparation of low-temperature instant salt-resistant integrated water-based thickener for fracturing fluid

[0055] (1) By adding an appropriate amount of distilled water, the total mass of the monomer is controlled at 17.5% AM, 7.5% AA, 3% ODAAC and 1% SMA hydrophobic functional monomer, 10% AMPS salt-tolerant monomer, 0.2% chelating agent EDTA , the total mass of the reaction system is 1000 g, and the solution is dissolved by magnetic stirring;

[0056] (2) Use 30% NaOH solution to adjust the pH of the system to 6.8;

[0057] (3) Lower the temperature in an ice-water bath, and when the system temperature drops to 2°C, add the monomer solution into a thermos;

[0058] (4) After passing the nitrogen for 40 minutes, add the initiator in an amount of 0.072% (calculated based on the total mass of the monomer) m((NH 4 ) 2 S 2 o 8 ):m(NaHSO 3 ):m(Vc):m(V 50 )=9:4:5:2, when the solution became viscous, the nitrogen flow was stopped, and after standing for 5 h, a white...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com