A method of making a paper tray

A technology of paper trays and paper rolls, which is applied in the direction of cardboard items, machining/deformation, etc., can solve the problems of large floor space, high cost of machine-made paper trays, and high waste rate of manual paper trays, so as to save floor space , reduce equipment purchase and use costs, and produce high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

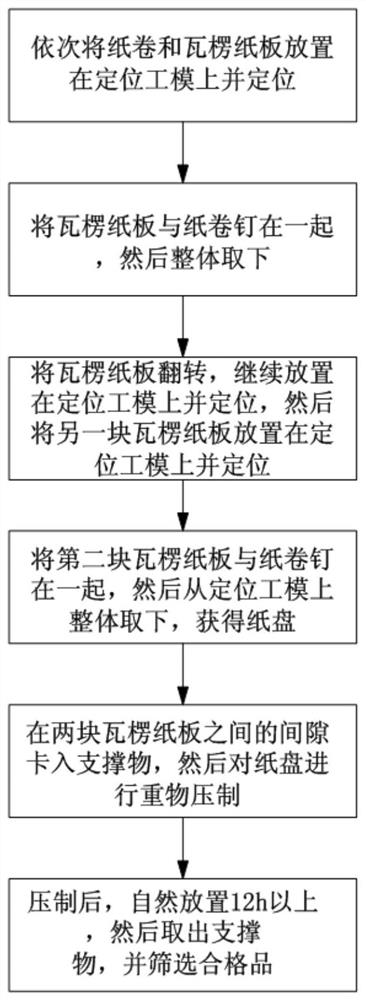

[0042] The invention provides a method for making paper trays, aiming to solve the problems of high waste rate in manual paper trays and high cost and large occupied space in machine-made paper trays. The process of the present invention is mainly divided into several major steps of corrugated cardboard processing, paper tray making, and packaging, which are respectively as follows:

[0043] 1. Corrugated cardboard processing

[0044] First of all, choose corrugated cardboard with 3 layers and C-type corrugation as the surface of the paper tray.

[0045] Then, a number of corrugated cardboards of the same size and specification are stacked sequentially in the order of alternating front and back, and the stacking height does not exceed 1m (usually 5-10 cardboards are stacked). Then press the stacked corrugated cardboard, the pressure is greater than 1 ton, and the pressing time is more than 7 days. After pressing, let it stand naturally for more than 3 days, and then select q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com