Steel wire rope core conveying belt for TBM and preparation method thereof

A technology of steel wire rope core and conveyor belt, applied in the field of steel wire rope core conveyor belt for TBM and its preparation field, can solve the problems of unsuitability for slag removal of tunnel boring machine, high resistance of steel wire rope core conveyor belt, poor overall bending flexibility of the conveyor belt, etc. To achieve the effect of small resistance, consistent tension, high flame retardant safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

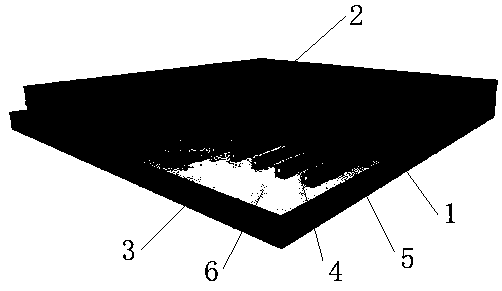

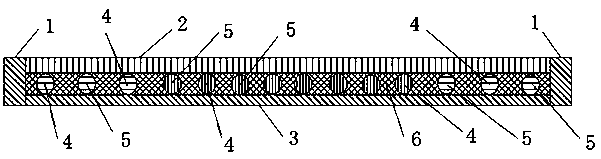

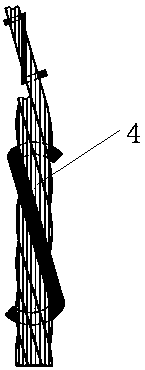

[0029] like figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment includes upper and lower covering rubber layers 2, 3, a middle core rubber layer 6, an edge rubber layer 1, multiple left-reading steel wire ropes 4 and multiple right-reading steel wire ropes 5. The left and right direction steel wire ropes 4 and 5 are arranged at intervals and distributed in the middle core rubber layer 6 . The top and bottom of the middle core rubber layer 6 cover the upper and lower cover rubber layers 2 and 3 respectively, and the left and right sides cover the edge rubber layer 1 respectively. The diameter of the left and right wire ropes 4 and 5 in the middle part is any value in 4-5mm, and the spacing is any value in 8-10mm. The diameters of the left and right wire ropes 4 and 5 on both sides are any value in 4-5mm, and the spacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com