Fullerene-based super wear-resistant light-cured coating and its application

A hydroxyfullerene and fullerene technology, applied in the field of coatings, can solve the problems of unstable wear resistance, wear resistance of wear-resistant coatings, limited scratch resistance, etc., and achieve long-term wear resistance and good wear resistance. , Good effect of symmetrical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of acrylic acid modified hydroxyfullerene is:

[0035] (1) Weigh a certain amount of fullerene and place it in a round-bottomed flask, add 98% concentrated sulfuric acid dropwise in an ice-water bath, and disperse it ultrasonically for 0.5-1h to obtain a dark green suspension solution, then vigorously stir in an ice-water bath Add distilled water dropwise and then add NaNO 3 , heated up to 100°C-120°C under the protection of an inert gas, stirred for 3-4h, cooled, stirred in an ice-water bath to obtain a tan solution, filtered, and the clear liquid was obtained;

[0036] (2) Use 3mol / L NaOH solution to adjust the pH value of the clear liquid obtained in step (1) to 10-12, so that a large amount of suspended matter gradually darkens in the solution, and finally becomes an opaque solution, and stands for 3-4h Make the precipitation complete, and use a centrifuge to centrifuge at 3500-5000r / min for 10-15min to obtain brown solid and brown liquid, th...

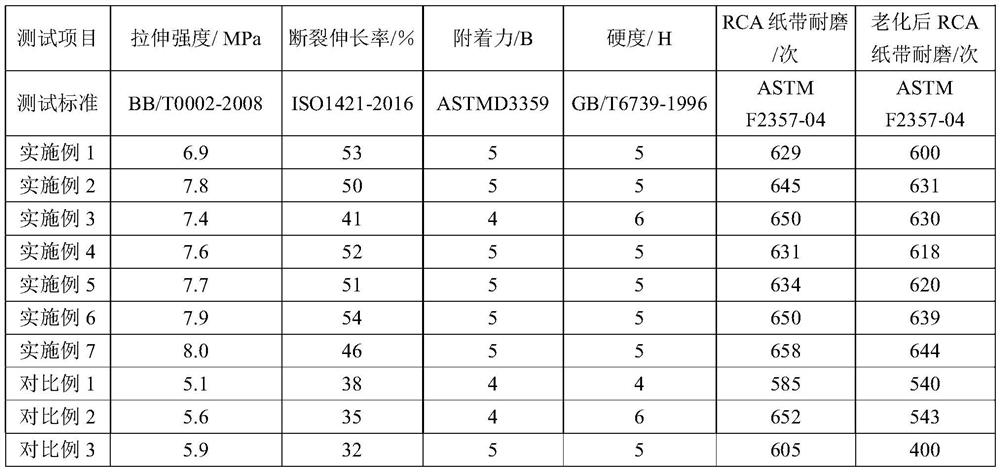

Embodiment 1

[0042] (1) Weigh 30 parts of acrylate oligomer, 15 parts of acrylic acid monomer, 3 parts of H-fullerene, 0.1 part of photoinitiator 1173, 0.02 part of leveling agent BYK-333, 0.1 part of dispersant SRE-4029 , 0.1 part of defoamer BYK1797, first add acrylate oligomer, acrylate monomer and modified fullerene into the reaction kettle, stir at 800r / min for 2 hours, and add leveling agent in turn during the continuous stirring process , defoamer, dispersant, and then add photoinitiator to make it evenly mixed, that is, to prepare a super wear-resistant light-cured coating based on fullerene;

[0043] (2) Apply the fullerene-based super-abrasive light-curable coating obtained in step (1) on the tinplate, and cure it to form a film under UV light to obtain a fullerene-based super-abrasive light-curable coating.

Embodiment 2

[0045] (1) Weigh 40 parts of acrylate oligomer, 24 parts of acrylic acid monomer, 4 parts of D-fullerene, 0.5 part of photoinitiator 184, 0.06 part of leveling agent BG2020, 0.3 part of dispersant SRE-4026X, 0.4 Defoamer BYK052, first add acrylate oligomer, acrylate monomer and modified fullerene into the reactor, stir at 1000r / min for 1h, add leveling agent, Foaming agent, dispersant, and photoinitiator are added to make it evenly mixed, that is, a super wear-resistant photocurable coating based on fullerene is prepared;

[0046] (2) Apply the fullerene-based super-abrasive light-curable coating obtained in step (1) on the tinplate, and cure it to form a film under UV light to obtain a fullerene-based super-abrasive light-curable coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com