Cloth-rope-shaped wrinkling device

A rope-like and cloth technology, applied in the direction of fabric surface trimming, textile and papermaking, etc., can solve the problems of single wrinkle pattern, poor operation safety, low production efficiency, etc., and achieve convenient operation, low cost investment and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

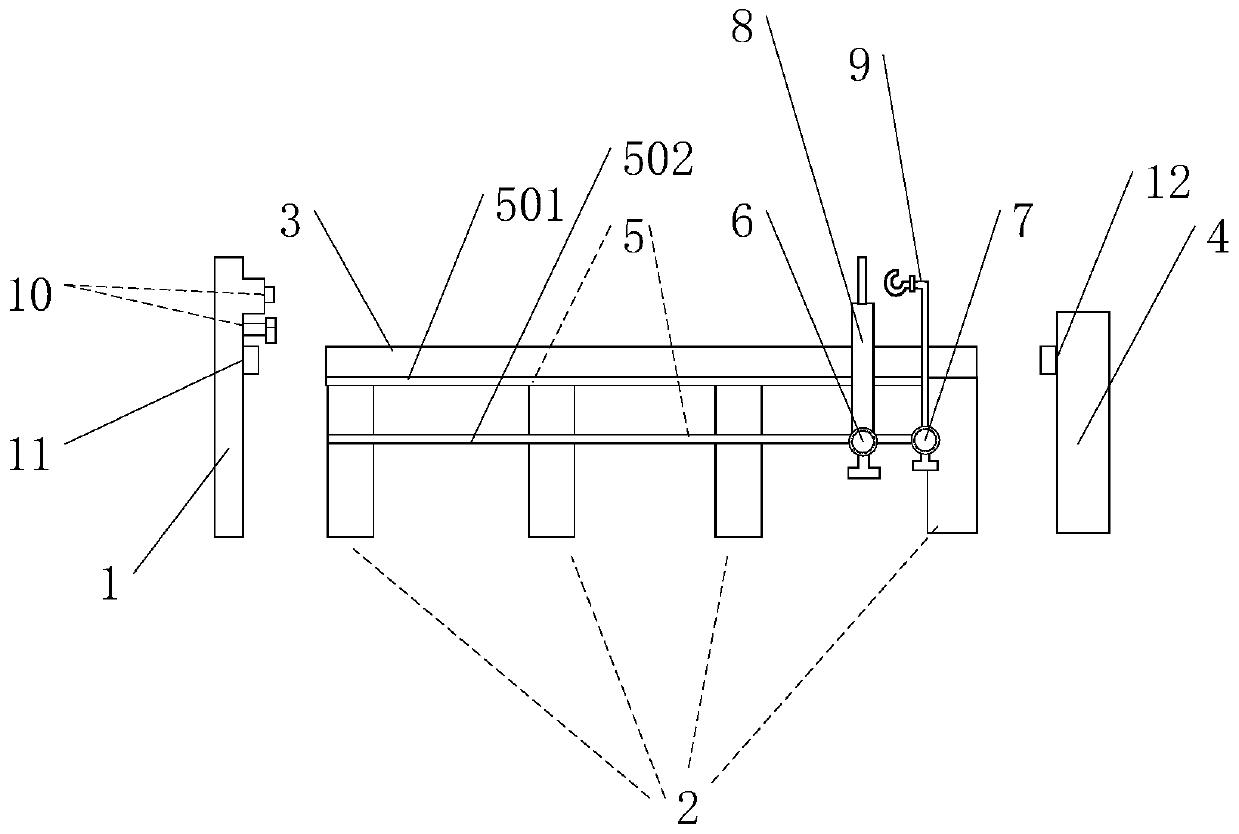

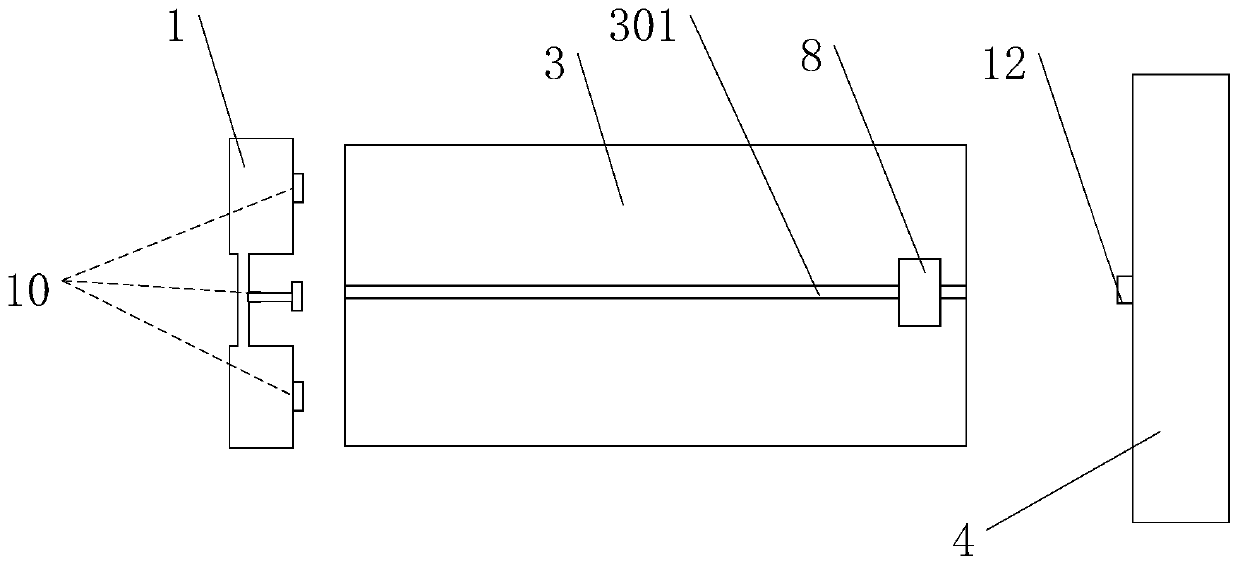

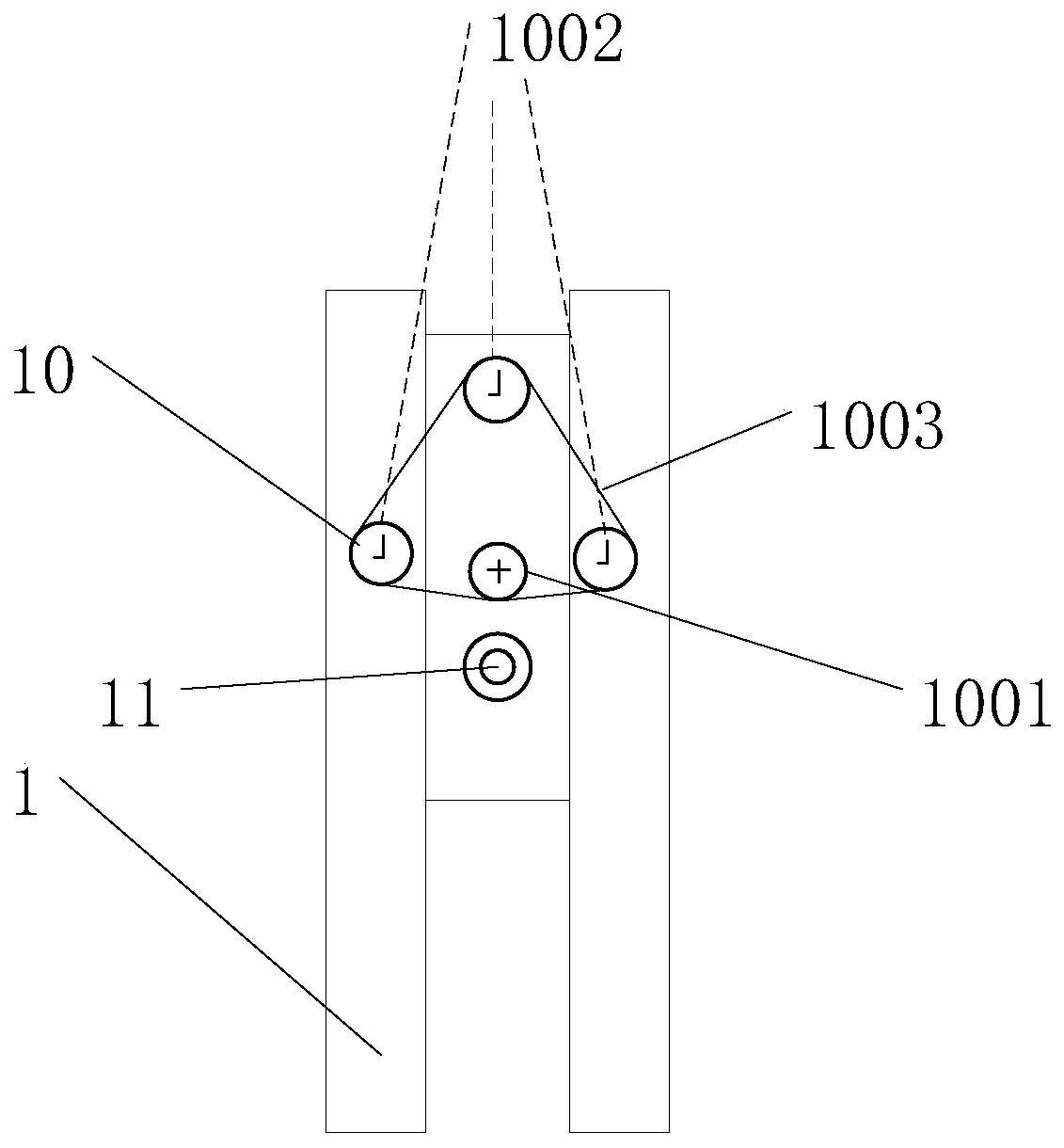

[0023] Such as Figure 1-5 As shown, a fabric rope-shaped wrinkling device in this embodiment includes a fixed table 1, a support group 2, a horizontal baffle 3 and a cloth ejecting frame 4, and the support group 2 is fixed on the ground. In order to stabilize the device, the bracket set includes 4 brackets, and the 4 brackets are evenly arranged at an interval of 3.5 meters. The fixed table 1 and the cloth withdrawal rack 4 are located on both sides of the bracket group 2, and the bracket group 2 is provided with a cross bar group 5, and the bracket group 2 is fixed by the cross bar group 5, and above the cross bar group 5 A horizontal baffle 3 is provided, and the cros...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap