Supercharged dual-purpose stove for heating and bathing

A dual-purpose furnace and heating pipe technology, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems of reducing combustion efficiency, air pollution, insufficient gas pressure, etc., to ensure gas volume, ensure The effect of gas pressure

Active Publication Date: 2020-07-28

NINGBO FOTILE KITCHEN WARE CO LTD

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The burner is burned by mixing air and gas. There is a large amount of nitrogen in the air. After high-temperature combustion, a large amount of nitrogen oxides will be produced, and nitrogen oxides will cause air pollution. At the same time, part of the nitrogen will take away heat and reduce combustion efficiency.

In addition, as the core component of the expansion tank, after a long period of use, the lack of air pressure often occurs, which causes the internal pressure of the system to increase continuously during the operation of the dual-purpose furnace, and usually needs to be repaired and supplemented with nitrogen.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0045] Example 2, such as Figure 4 As shown, the hollow fiber air separation membrane 7 is not provided in this embodiment, and refer to Embodiment 1 for other structures.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

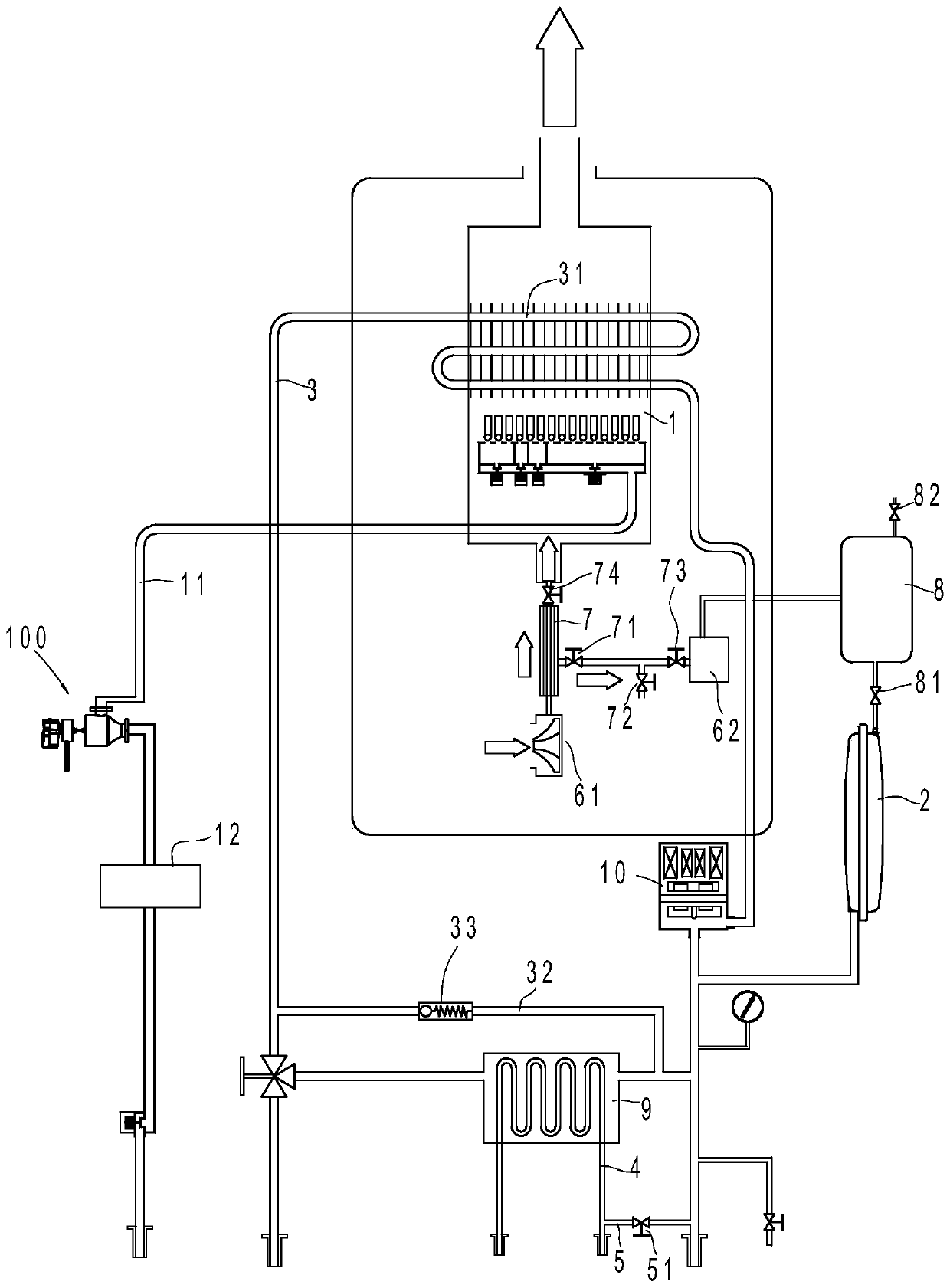

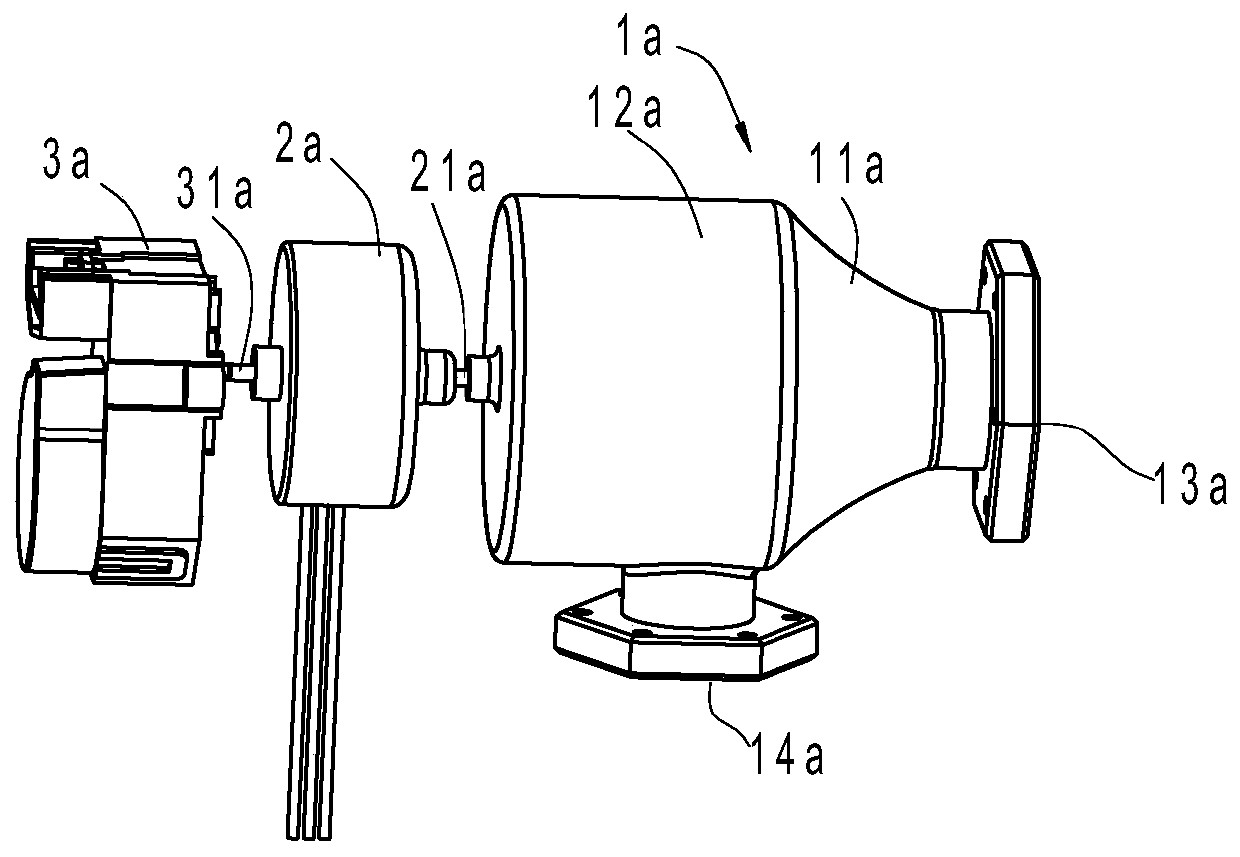

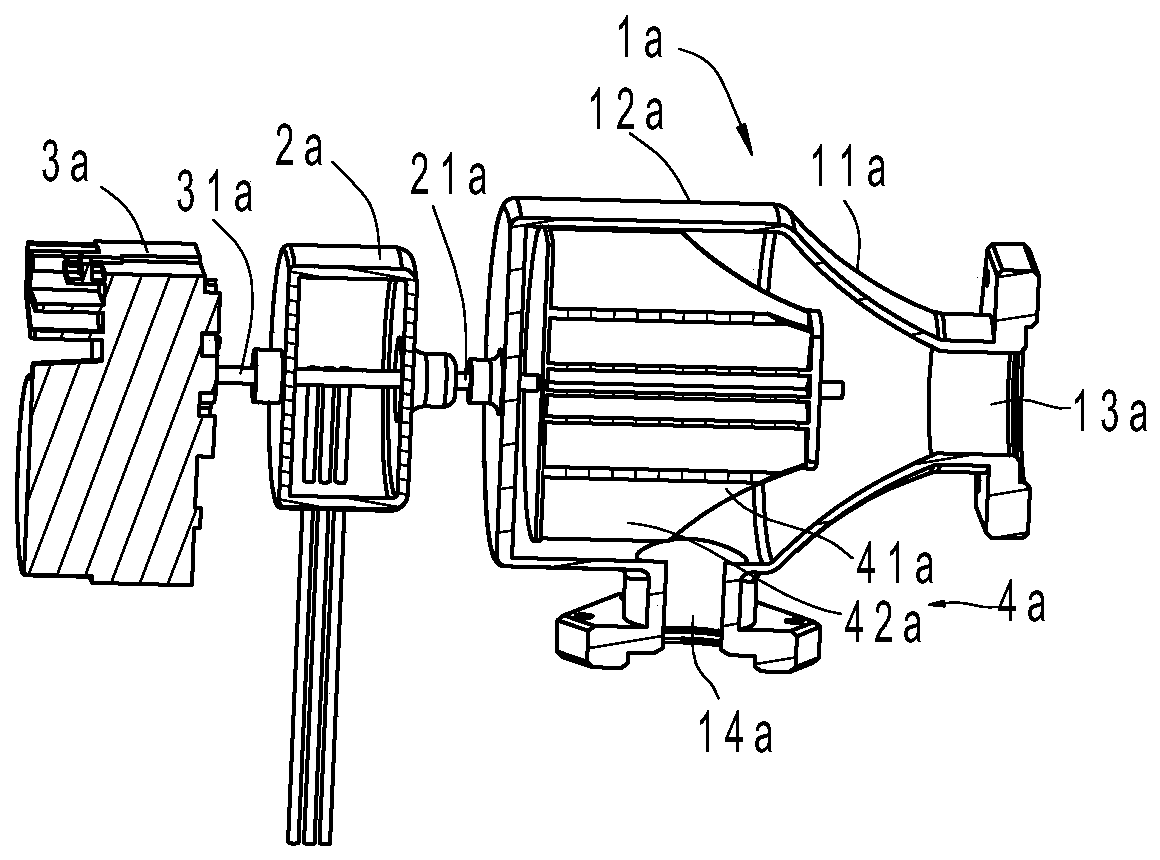

The invention relates to a supercharged dual-purpose stove for heating and bathing. The supercharged dual-purpose stove for heating and bathing comprises a combustor and a fuel gas inlet pipe communicating with the combustor, and is characterized in that a supercharge ratio control device is arranged on the fuel gas inlet pipe and comprises a shell, an impeller, a rotary motor and a pushing motor.The shell is provided with a cone part; a gap is formed between the impeller and the cone part; a rotary shaft of the rotary motor stretches into the shell and is connected with the impeller; and anoutput shaft of the pushing motor is connected with a case of the rotary motor and can drive the rotary motor to move back and forth, so that the gap between the impeller and the cone part can be adjusted. The gap between the impeller and the shell can be adjusted, so that the gas inlet flow can be adjusted; and meanwhile, the impeller rotates to realize a fuel gas supercharging function.

Description

technical field [0001] The invention relates to a dual-purpose stove for heating and bathing. Background technique [0002] The basic structure of the dual-purpose furnace includes gas inlet pipe, heating pipe, bathing pipe, plate heat exchanger, burner and expansion tank. The gas inlet pipe is equipped with a gas proportional valve, which controls the opening of the gas passage through an electromagnet. The size thus controls the gas flow. The gas flow rate is greatly affected by the gas supply pressure. When the gas supply pressure is insufficient in winter, the gas proportional valve cannot guarantee the gas flow even if it reaches the maximum opening, and the maximum gas flow can only be less than the gas supply pressure. The maximum and minimum loads of gas heating and hot water dual-purpose boilers shift downwards, resulting in failures such as insufficient maximum heat load, difficulty in ignition, and flameout at minimum load; Faults such as unstable gas output. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F24H1/52F24H9/18F24H9/20

CPCF24H1/52F24H9/1836F24H9/2035

Inventor 卢吉徐金金周高云徐德明

Owner NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com