Volute molded line generation method of centrifugal fan

A centrifugal fan and volute technology, which is applied in the field of volute profile generation of centrifugal fans, can solve the problems of generating irregular noises, having little guiding significance for the actual design of the volute, and unsmooth flow field at the multi-section splicing splicing. The effect of reducing noise and smooth flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The above formula (1) is improved as:

[0047]

[0048] Where C is a constant: 02 ,D 2 is the diameter of the base circle of the volute.

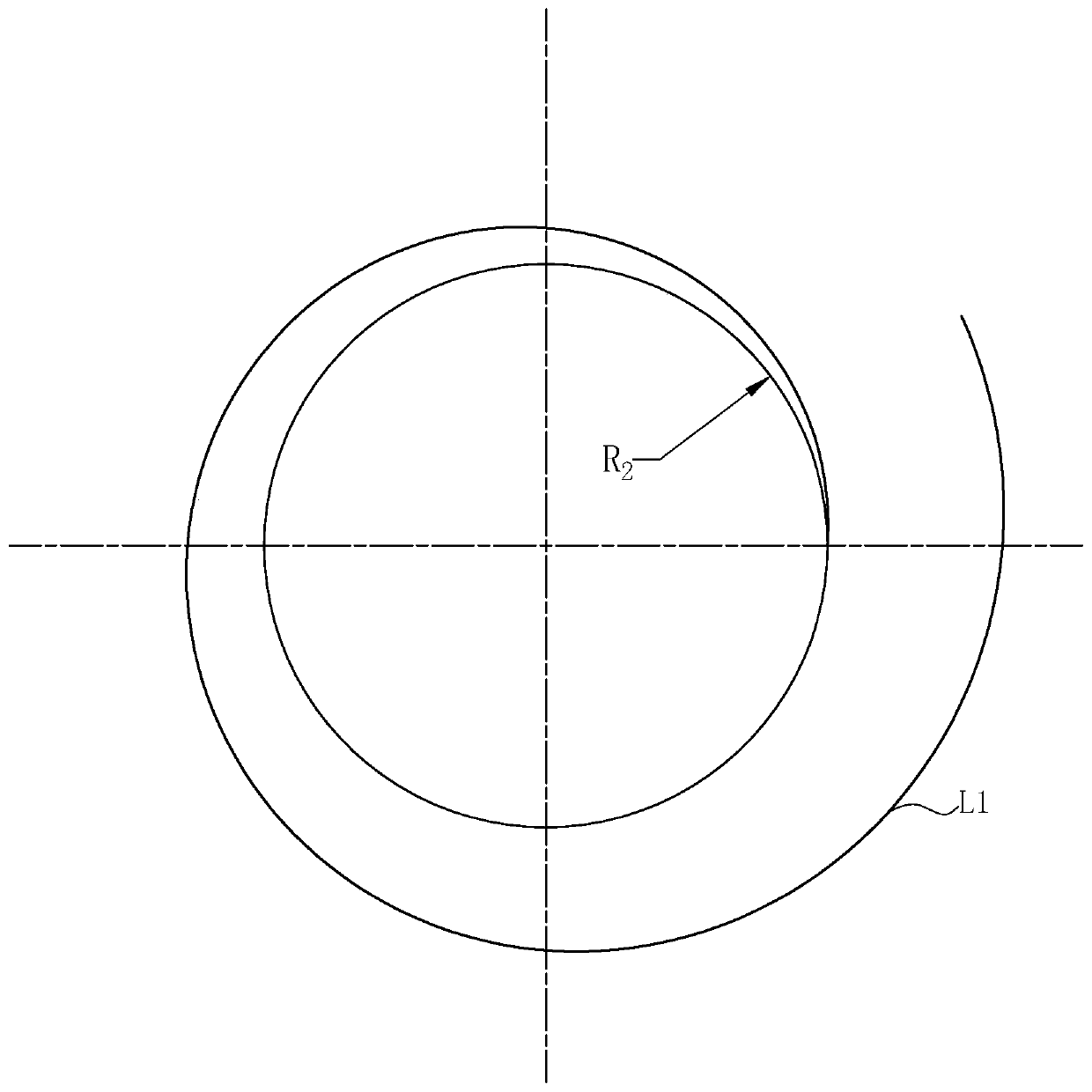

[0049] Thus, see figure 1 , the profile equation of the basic profile L1 is r=117*exp(0.077*θ / 180*π), and through the method of this embodiment, the outer circle of the volute profile is overall increased, and its profile equation is: R =(117+3)*exp(0.077*θ / 180*π).

Embodiment 2

[0051] The method in the above-mentioned embodiment 1, when the size is limited and the flow rate variation range is large, will cause obvious attenuation at low flow rates.

[0052] Therefore, in this embodiment, the C in the first embodiment is changed so that it is no longer an invariable constant, but is changed to a variable that gradually decreases from the starting point to the end point of the profile line. While the gap at the cochlear tongue is large, the overall width is not increased, and the impact on small flow attenuation is reduced.

[0053] One way is to make C vary linearly. At the start point (θ=0°) of the volute profile, C=3, and at the end point (θ=360°), C=0. In this embodiment, C changes linearly from the starting point to the ending point. Specifically, it can be expressed as:

[0054]

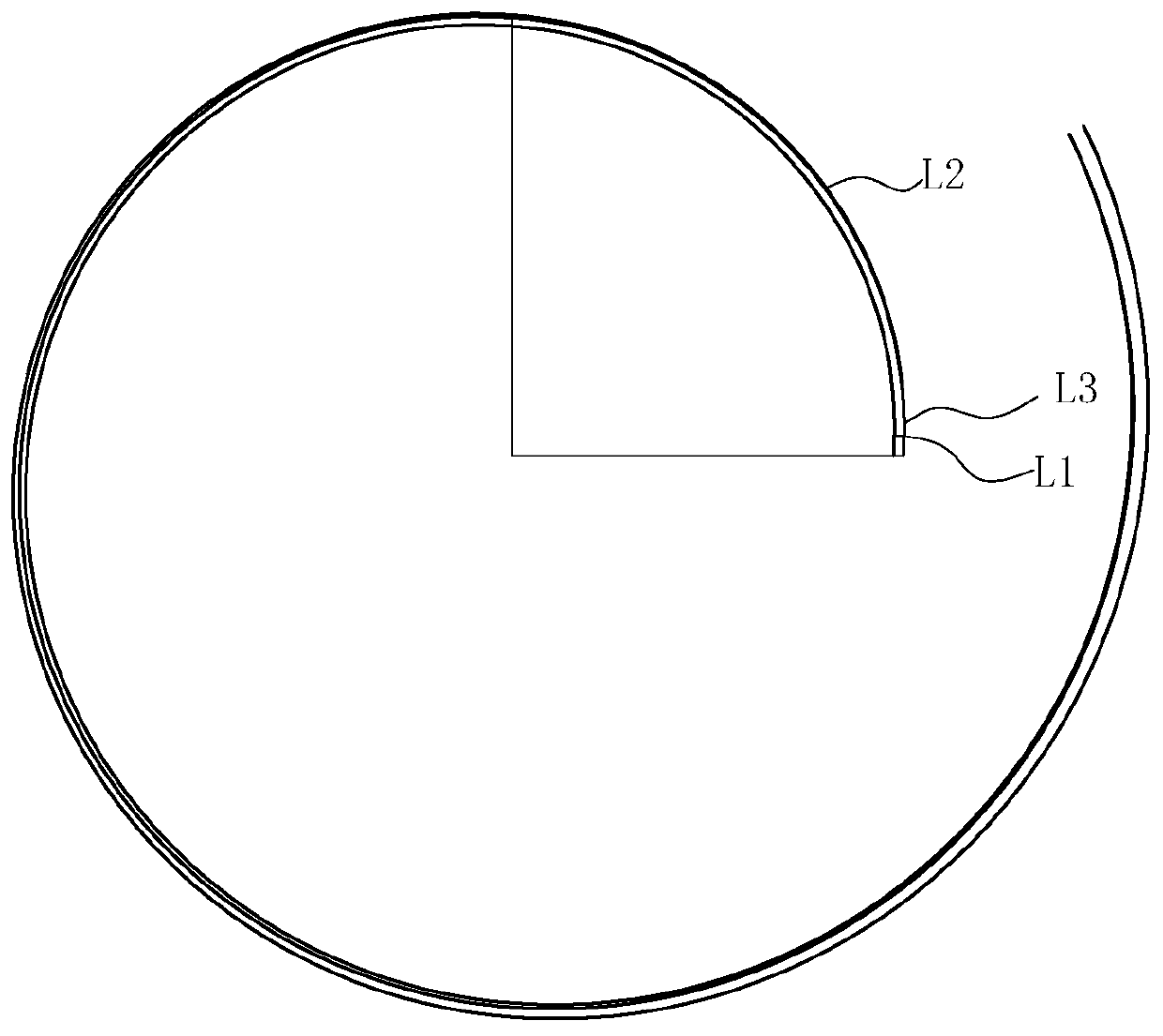

[0055] see figure 2 , the innermost one is the base profile L1, the outermost one is the volute profile L2 obtained in Example 1, and the middle one is the volute ...

Embodiment 3

[0064] In the actual optimization design process, refer to the above formula (2): The value range of m is generally larger. In order to adapt to such a wider range of changes in the value of m, in this embodiment, this is further optimized. The radius of the base circle remains unchanged, and only the value of m is changed. From the perspective of noise reduction, m adopts the method of gradually decreasing from the starting point to the ending point, that is, the gap at the cochlear tongue increases.

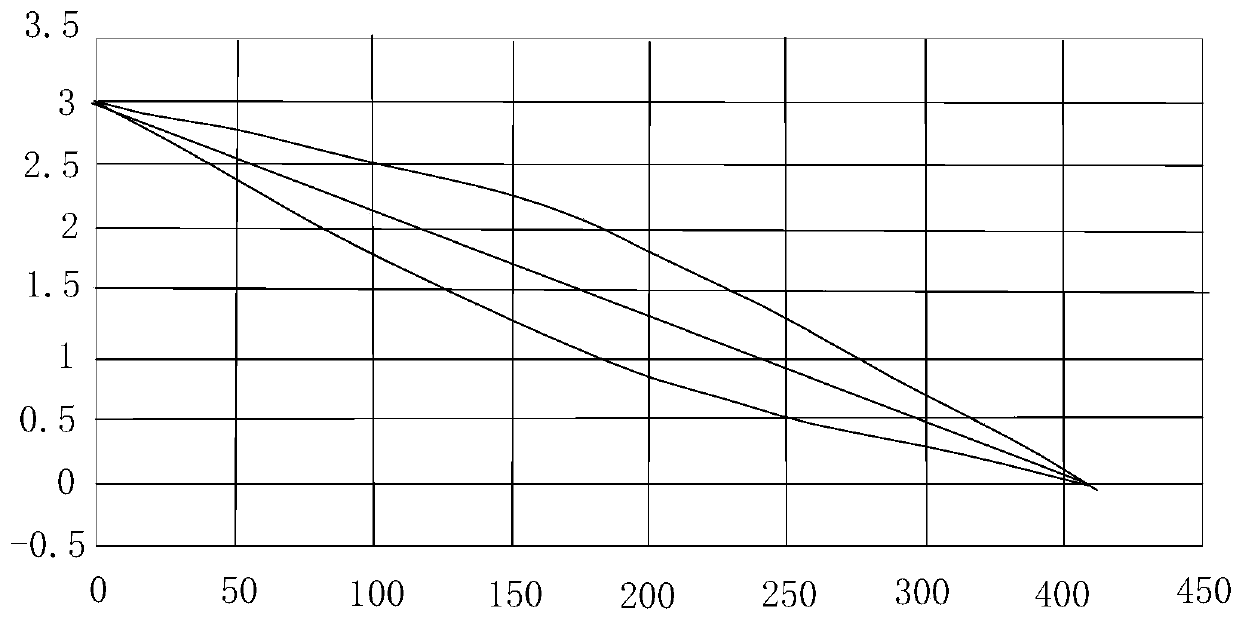

[0065] Taking a certain type of range hood currently on the market as an example, the maximum efficiency point m is 0.065, and the maximum air volume point m is 0.095. m gradually decreases from the start point to the end point of the volute profile. One way is to make m vary linearly. At the start point (θ=0°) of the volute profile, m=0.095, and at the end point (θ=360°), m=0.065. Another method is to make m change nonlinearly, and the nonlinear change can also be divided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com