Composite material curing deformation simulation modeling method based on fiber placement track

A technology of curing deformation and simulation modeling, applied in design optimization/simulation, constraint-based CAD, instruments, etc., to achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

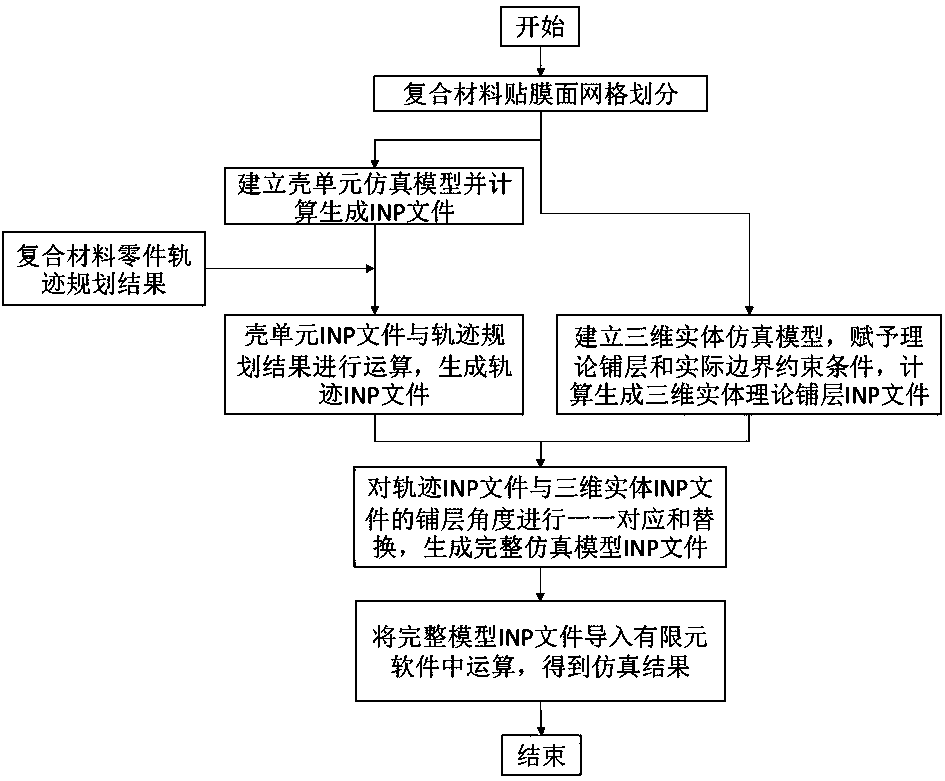

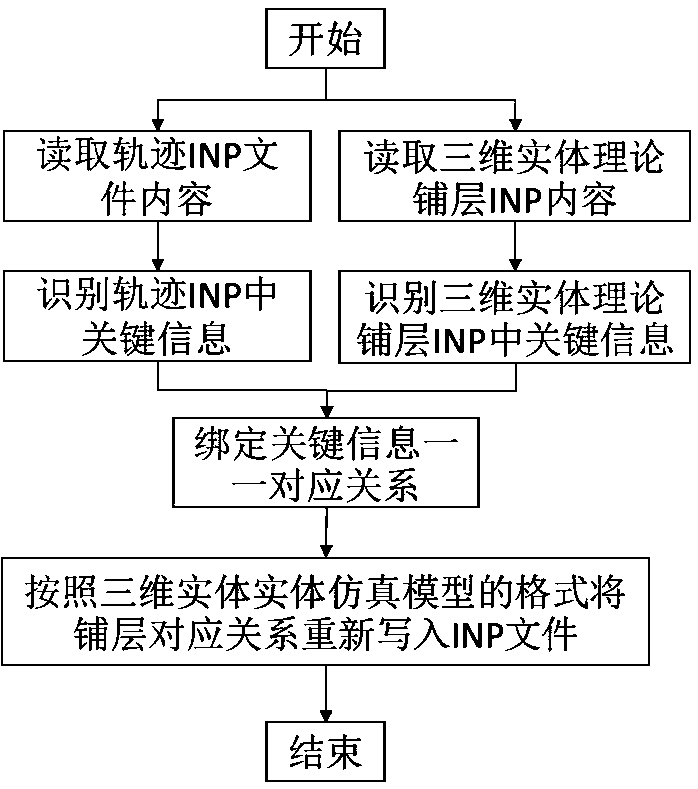

[0029] A simulation modeling method for solidification deformation of composite materials based on wire laying trajectory, such as figure 1 As shown, it mainly includes the following steps:

[0030] Step S1: In the finite element software, perform finite element mesh division on the film surface of the composite material part manufactured by the automatic wire laying equipment to form a shell element mesh model;

[0031] Step S2: Carry out simulation calculation on the shell element mesh model, and generate an INP file of the shell element mesh model including mesh node information;

[0032] Step S3: Import the INP file of the mesh model of the shell element into the automatic wire laying trajectory planning and design software, and perform calculations together with the results of the automatic wire laying trajectory planning of the composite material part to generate a fiber laying including grid nodes and fiber laying trajectory planning Trajectory INP file with angle info...

Embodiment 2

[0038] This embodiment is optimized on the basis of Embodiment 1. The shell element mesh model in the step S2 and the 3D solid theory layup INP file in the step S4 are generated based on the same mesh model. The INP file in the step S2 is a type of file generated by the finite element software, and the INP file records the model data and historical data of the finite element model, such as node coordinates, elements, material properties, and the like.

[0039] The automatic wire laying trajectory planning and design software described in step S3 is a necessary design software for the manufacture of composite material parts by using automatic wire laying equipment, which can realize the planning of wire laying trajectory according to the structural characteristics of composite material parts, and form the The result of the automatic laying trajectory planning of the composite material part. It should be noted that the geometric model used for trajectory planning of composite pa...

Embodiment 3

[0046] A simulation modeling method for solidification deformation of composite materials based on wire laying trajectory, such as figure 1 As shown, it mainly includes the following steps:

[0047] Step S1: In the finite element software Abaqus, perform finite element mesh division on the film surface of the composite material part manufactured by the automatic wire laying equipment;

[0048] In this embodiment, the finite element mesh division and analysis of the composite material parts is carried out by using the finite element analysis software Abaqus, and the film surface of the composite material part is imported into the Abaqus analysis software, and the film surface is meshed. Grid type and grid size are not required. In this embodiment, in order to facilitate subsequent operations and data processing and application, quadrilateral structured, type S4R grids are used for division, and after the grid division of all models is completed, the create mesh function is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com