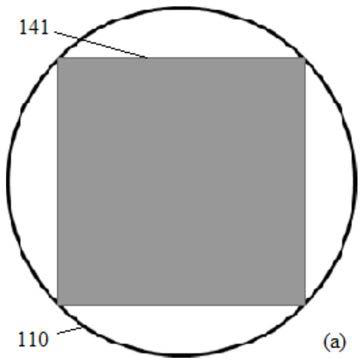

Silicon wafer/battery sheet, photovoltaic battery assembly, carrier and design and arrangement method

A photovoltaic cell and cell technology, which is used in photovoltaic power generation, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as debris and silicon wafer bending, and achieve low manufacturing costs, large effective packaging area, and high output power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0158] Each embodiment provides photovoltaic cell modules arranged in a variety of specifications, which are respectively embodiment 1-1, embodiment 1-2, embodiment 1-3, embodiment 1-4, embodiment 1-5, and embodiment 1-6; Example 2-1, Example 2-2, Example 2-3, Example 2-4, Example 2-5, Example 2-6, Example 2-7; Example 3- 1. Example 3-2, Example 3-3, Example 3-4, Example 3-5, Example 3-6; Example 4-1, Example 4-2, Example 4-3, The photovoltaic cell modules of Example 4-4, Example 4-5, and Example 4-6 are specifically shown in Table 1.

Embodiment 1

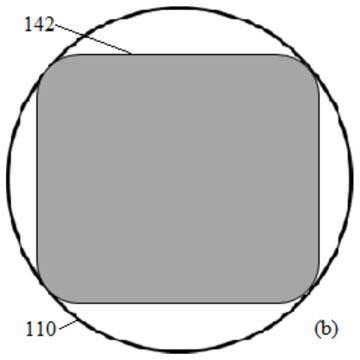

[0159] Taking Example 1 as an example, the design and arrangement method of photovoltaic cell modules is carried out according to the following process:

[0160] S1. Consider the size constraints of logistics and glass: use a 40-foot high container (length 12020mm, width 2350mm, height 2690mm) for transportation, consider the width of the glass to be less than 1.2m, and reserve sufficient loading and unloading errors to determine the photovoltaic cell module size The restriction conditions are: long side Y<2400mm, short side X<1150mm.

[0161] S2. According to the above restriction conditions, suppose the arrangement of the cells in the photovoltaic cell module is as follows: all cells are arranged in m rows along the Y side of the photovoltaic cell module, m=13, 12, 11 or 10 or 9, all The x edges of the cells are arranged in n rows along the X edge of the photovoltaic cell module, n=6, and each cell is cut into f slices along the y direction, f=2 or 3. For different values of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com