Reaction injection molding technology for automobile spoiler

An injection molding and spoiler technology, applied in applications, flat products, household appliances, etc., can solve the problems of high equipment and mold costs, low mechanical properties, and injection mold ejection restrictions, and achieve low equipment and mold costs. The effect of product design freedom and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

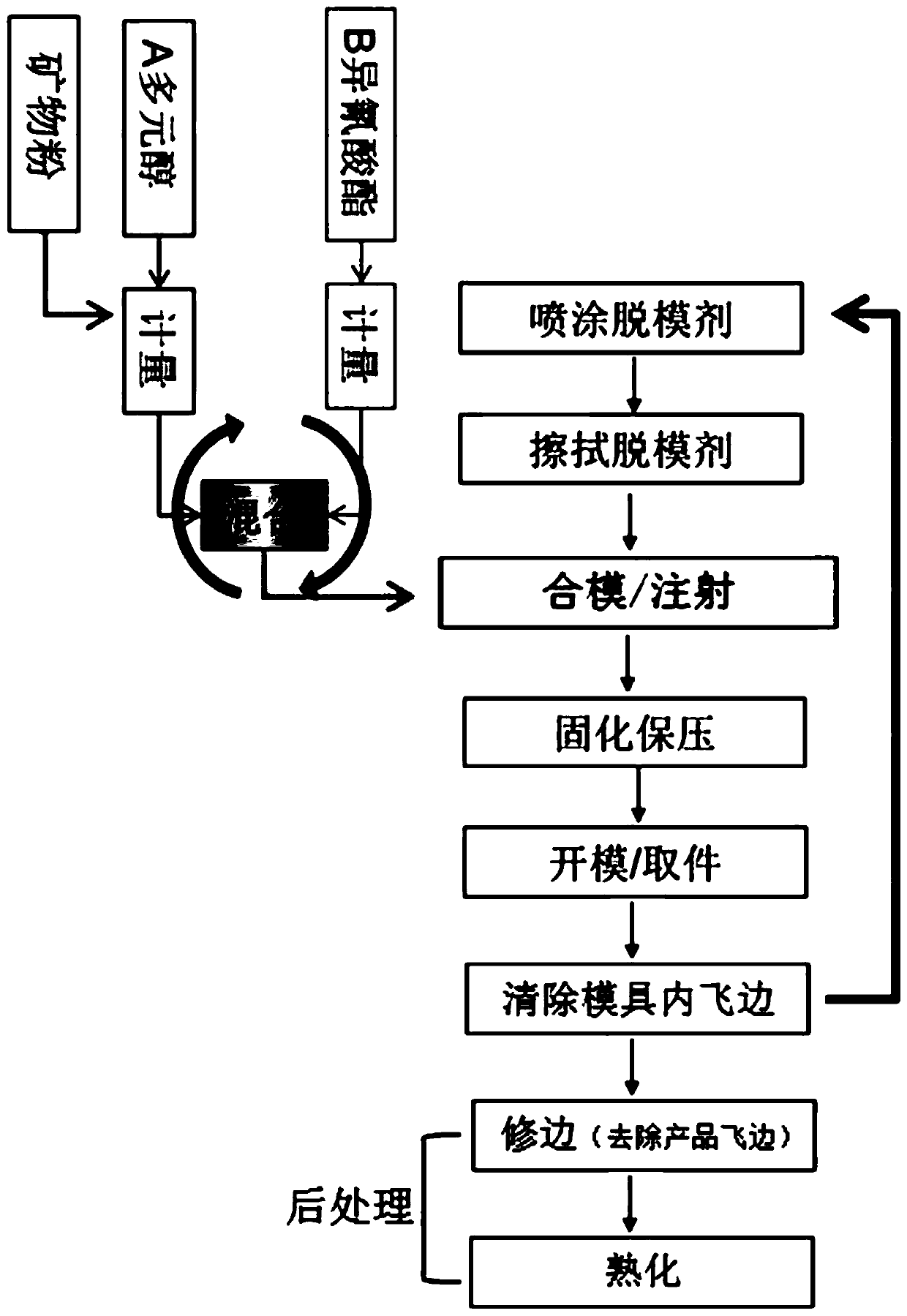

[0028] to combine Figure 1 to Figure 2 Shown, a kind of reaction injection molding process of automobile spoiler comprises the following steps,

[0029] Step 1: Clear the flash in the car spoiler mold;

[0030] Step 2: Spray release agent in the automobile spoiler mold;

[0031] Step 3: Wipe the release agent;

[0032] Step 4: closing the upper mold and the lower mold to form the automobile spoiler mold (mold closing);

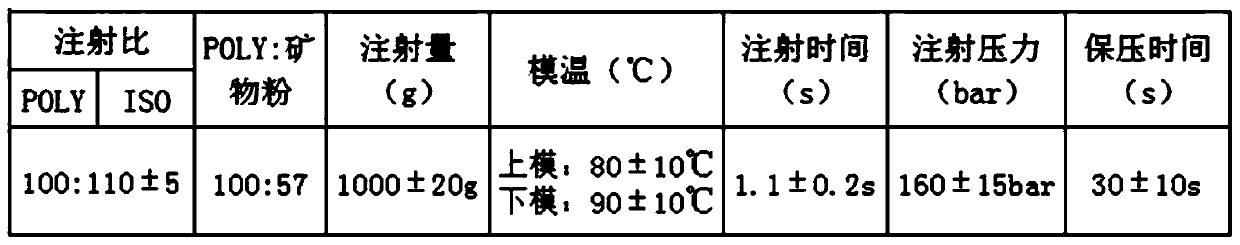

[0033] Step 5: Weigh polyether polyol (POLY), weigh isocyanate (ISO) and weigh mineral powder respectively, mix polyether polyol (POLY), weigh isocyanate (ISO) and weigh mineral powder to form a liquid, Make the injection ratio of polyether polyol (POLY) and isocyanate (ISO) 100:110, and make the ratio of polyether polyol (POLY) and mineral powder 100:57;

[0034] Step 6: Inject the liquid in Step 5 into the automobile spoiler mold with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com