Air conditioner high-low pressure pipe assembly

A high-low pressure, tube assembly technology, used in air handling equipment, heating/cooling equipment, engine sealing, etc., can solve the problems of high dimensional accuracy of sealing structure, high processing cost of welding structure, easy to scratch and damage, etc. , to achieve the effect of reducing product cost, convenient installation and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

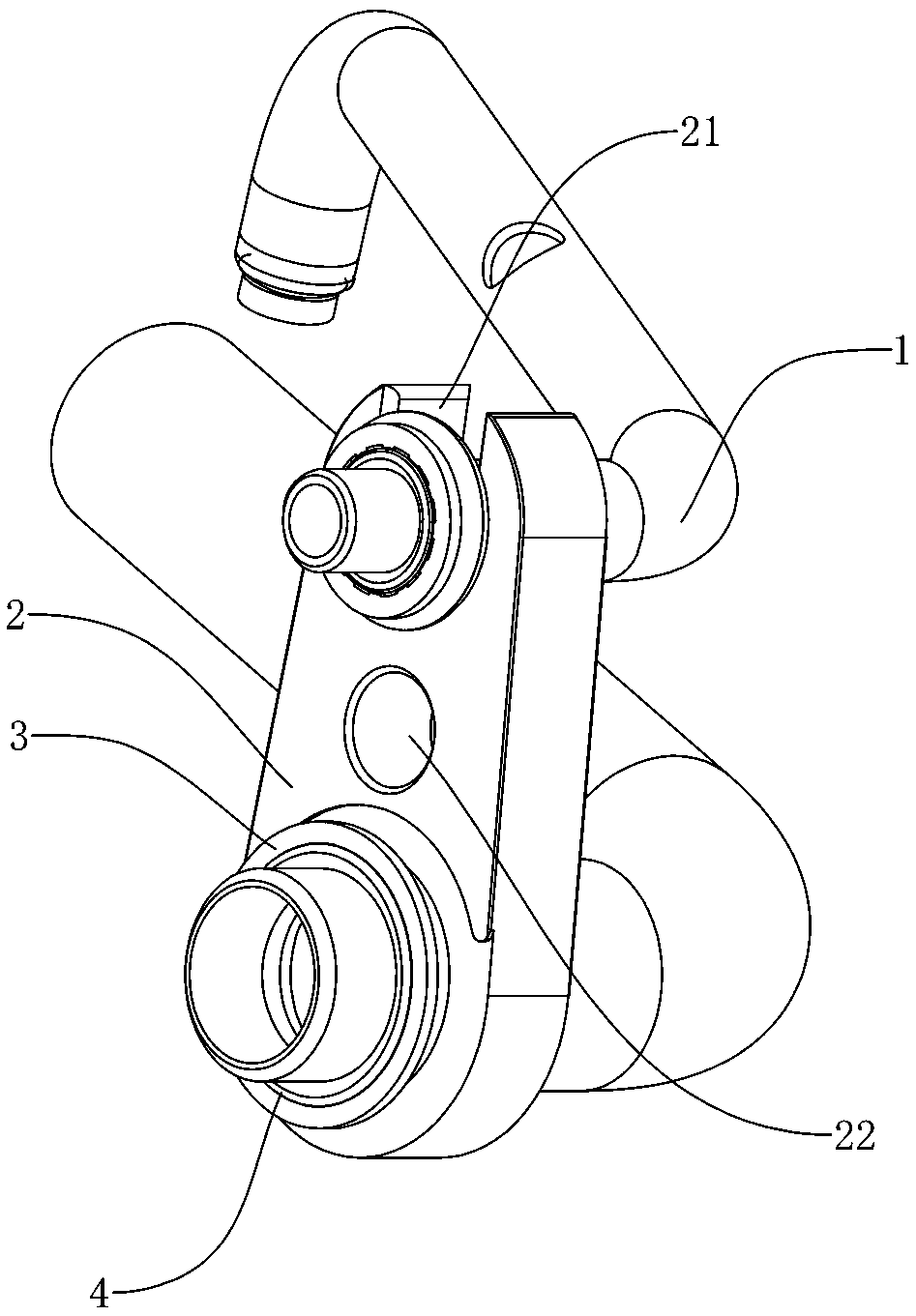

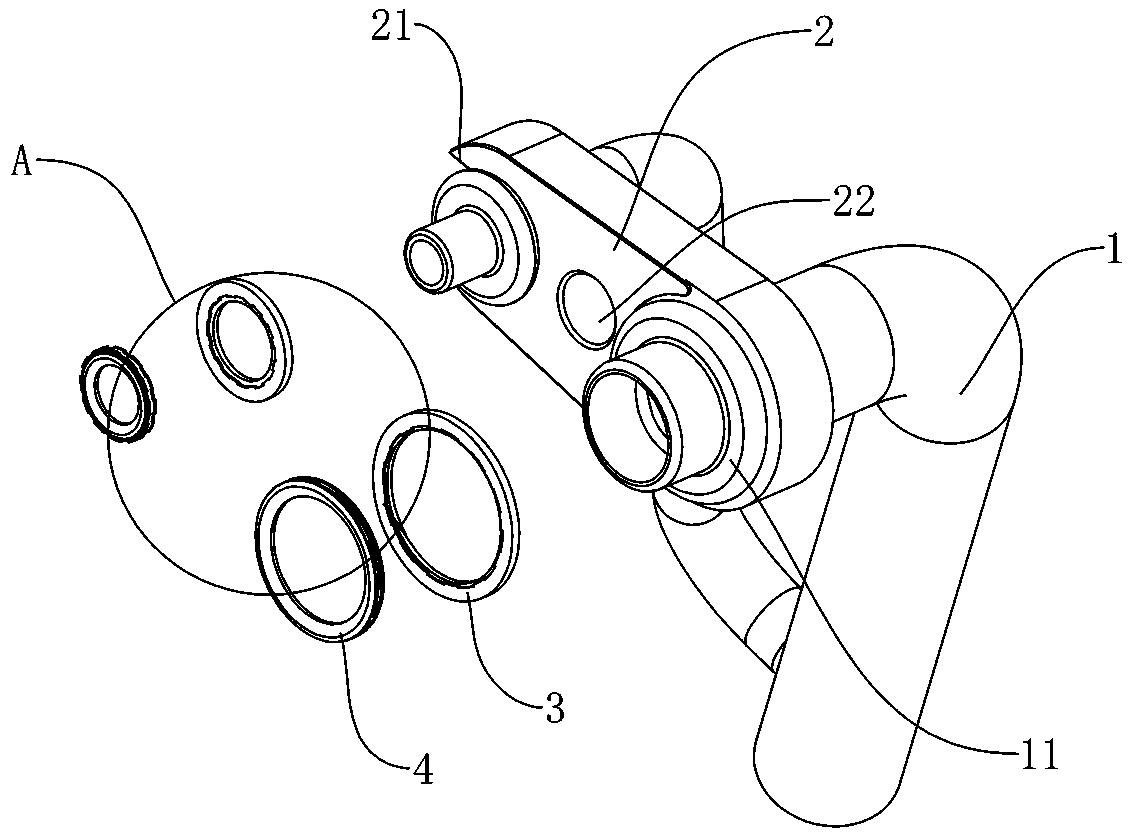

[0029] Such as figure 1 As shown, an air conditioner high and low pressure pipe assembly includes a high and low pressure pipe fitting 1 and an extruded sealing block 2 . The extrusion sealing block 2 is provided with a perforation for the high and low pressure pipe fittings 1 to pass through, and is used for the extrusion sealing of the pipe end of the high and low pressure pipe fittings 1; Positioning ring 11, and sleeved with a rubber ring 4 that abuts against the limiting ring 11 on one side and squeezes and seals on the other side. The block 2 is abutted to prevent the high and low pressure pipe fittings 1 from detaching from the extruded sealing block 2, and then the rubber ring 4 is used to extrude and seal the other side by abutting the limit ring 11 on one side. After the sealing block 2 is pressed, the extrusion sealing effect is realized, which has the effects of significantly reducing product cost and significantly improving sealing quality and convenience. It sh...

Embodiment 2

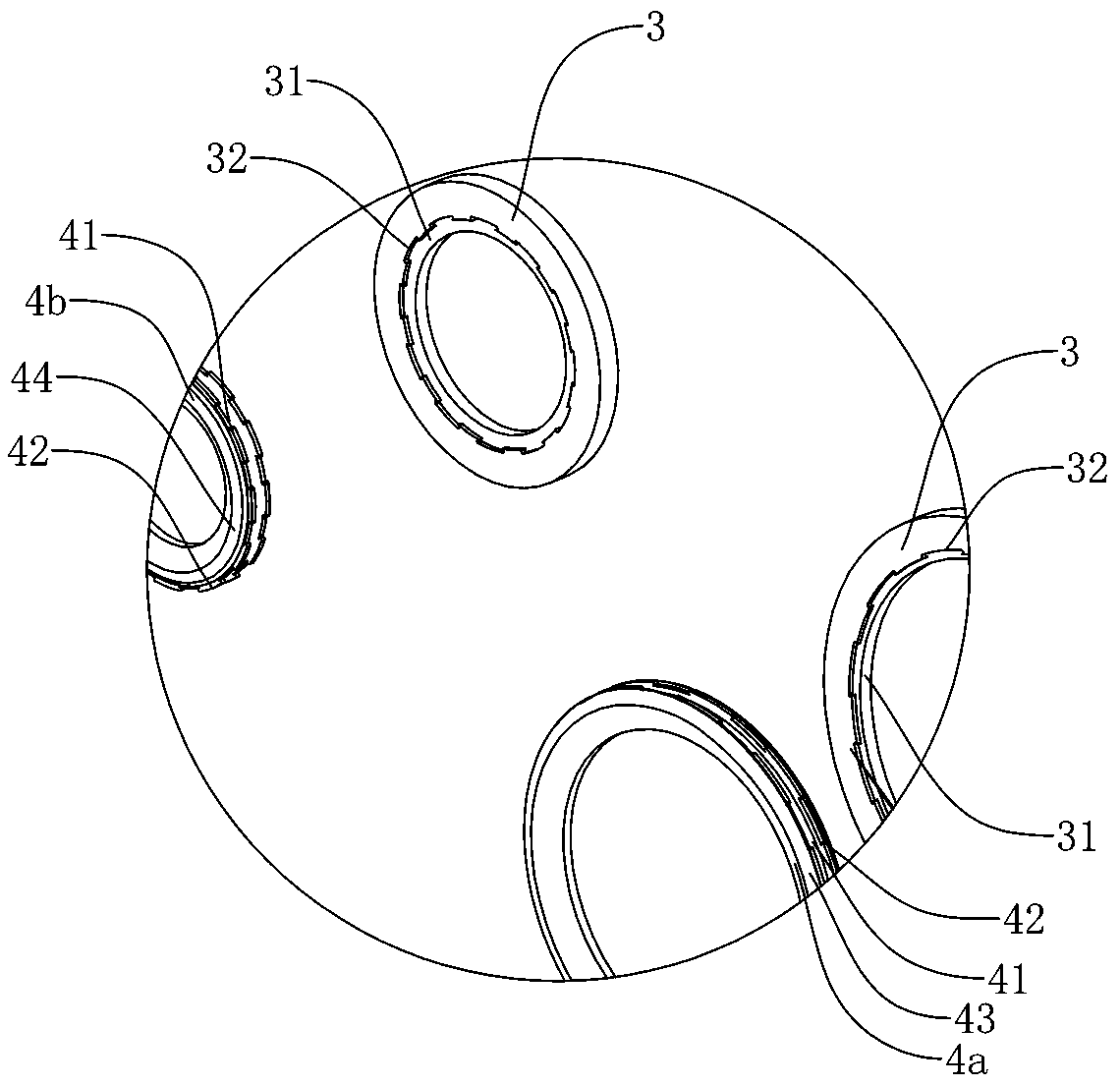

[0034] The difference between the second embodiment and the first embodiment is that the rubber ring 4 in the second embodiment is the second sealing ring 4b. Both sides of the second sealing ring 4b are provided with second sealing convex rings. The second sealing protruding ring 44 protrudes from the metal ring 3 , and the second sealing protruding ring 44 on one side abuts against the limiting ring 11 , and the second sealing protruding ring 44 on the other side is used for extrusion sealing. Therefore, the second sealing bead 44 passing through the two sides of the second sealing ring 4b respectively protrudes from the corresponding side, and the second sealing bead 44 on one side abuts against the limit ring 11, and the second sealing bead 44 on the other side The second sealing protruding ring 44 is used for extrusion sealing, thereby forming a stable protection for the second sealing ring 4b, which has the effects of convenient installation, significantly improved seali...

Embodiment 3

[0036] The difference between the third embodiment and the first embodiment is that the rubber rings 4 in the third embodiment are the first sealing ring 4a and the second sealing ring 4b. Both sides of the first sealing ring 4a are provided with first sealing protruding rings 43 . The first sealing protruding ring 43 protrudes from the metal ring 3, and the first sealing protruding ring 43 on one side abuts against the limit ring 11, and the first sealing protruding ring 43 on the other side is used for extrusion sealing; Both sides of the second sealing ring 4 b are provided with second sealing protruding rings 44 . The second sealing protruding ring 44 protrudes from the metal ring 3, and the second sealing protruding ring 44 on one side abuts against the limit ring 11, and the second sealing protruding ring 44 on the other side is used for extrusion seal. Therefore, the first sealing ring 4a and the second sealing ring 4b are matched and connected with the corresponding ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap