Easy-to-assemble central motor adopting first-stage gear speed reduction transmission

A technology of gear reduction and mid-mounted motor, which is applied to wheel transmissions, vehicle gearboxes, rider drives, etc., and can solve the problem of easily damaged shaft gears, high cost of selection of one-way clutches, and one-way Problems such as difficulty in clutch manufacturing can be achieved to enhance positioning reliability and stability, improve disassembly convenience, and achieve the effect of small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

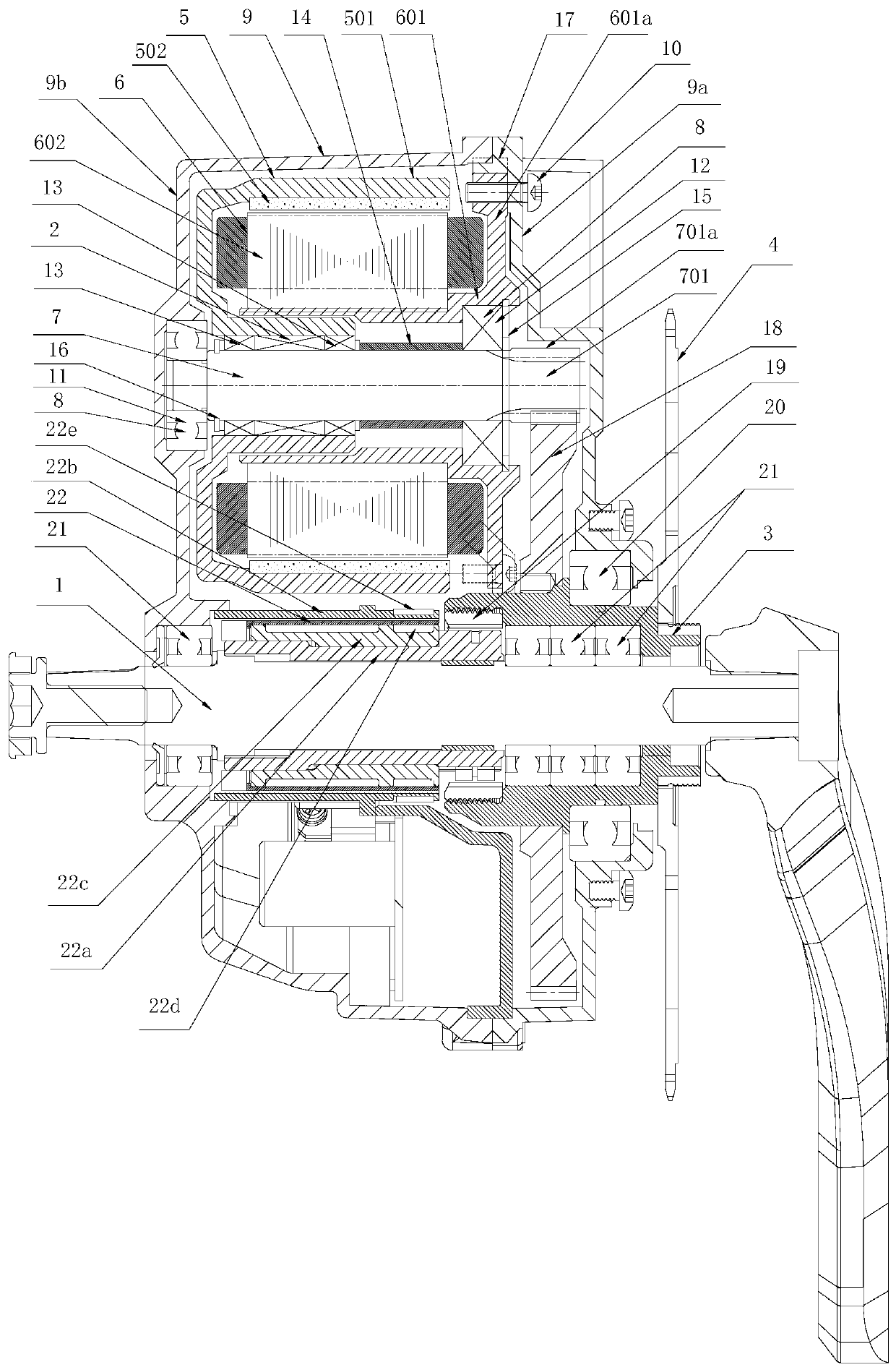

[0033] Embodiment: combine below figure 1 The specific implementation of the easy-to-assemble mid-mounted motor with one-stage gear reduction transmission provided by the present invention is described as follows:

[0034]The easy-to-assemble central motor provided by the present invention adopts one-stage gear reduction transmission. Mandrel 7, shaft teeth 701a, two mandrel bearings 8 (respectively the first mandrel bearing 11 and the second mandrel bearing 12), housing 9, screws 10, two rotor bearings 13, movement Shaft sleeve 14, first axial locking collar 15, second axial locking collar 16, large gear 18, one-way ratchet mechanism 19, chainring positioning sleeve supporting bearing 20, four central shaft supporting bearings 21 Together with the torque sensor 22.

[0035] like figure 1 As shown, the same as the known technology, the housing 9 is equipped with a motor core, a central shaft 1, a one-way clutch 2, and a first-stage gear reduction mechanism, and the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com