Preparation method of elastic cigarette turnover box

A turnover box and flexible technology, applied in rigid containers, bottle/can parts, containers, etc., can solve the problems of white pollution, environmental protection, short service life and large packaging volume of turnover boxes, and achieve easy promotion and processing efficiency. High and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

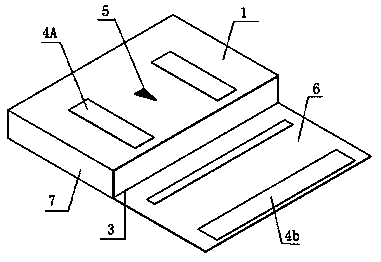

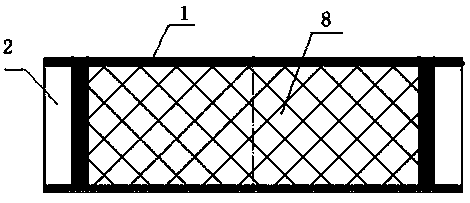

[0031] One embodiment of the present invention is a method for preparing an elastic turnover box for cigarettes, which includes the following steps: material selection, selecting a fixed material and an elastic material, using the fixed material as the front and rear materials of the turnover box, and selecting the elastic material as the two sides of the turnover box. side material. Specifically, the fixed material can be hard corrugated board. The hard corrugated board is thermosetting, has good high-temperature dimensional stability, and has a light weight per unit volume, which is suitable for transportation and can reduce the handling load; its elastic material Elastic bands can be used to constrain through the elasticity of the elastic bands.

[0032] Plywood production, with the package of the standard cigarettes delivered as the capacity reference, the fixed material is cut to size to obtain two core boards; and canvas is placed on the two core boards to obtain two ply...

Embodiment 2

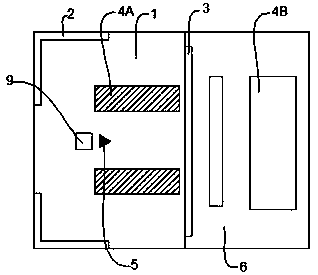

[0040] Based on the above-mentioned embodiments, another embodiment of the present invention is that the method for preparing the flexible turnover box for cigarettes further includes step E of identifying the box body, and installing an identification code 9 on the side wall of the box body.

[0041] The identification code 9 can be in various ways. For example, the UIG algorithm is used to group all tags according to the company code and product code, and then generate two initial tag identification codes for each group based on the collision information of the product serial number. Finally, by continuously subtracting or adding 1 to the initial tag identification code, the identification code enters information. The principle is that the unique identification code ID is installed on the box body and is attached to the object to be identified. The reader is used to send a signal that can provide energy and commands to the tag, and the tag sends its identification code back ...

Embodiment 3

[0056] Based on the above-mentioned embodiment, another embodiment of the present invention is that during the process of the prototype of the box, the blank of the box is in a state of natural absorption, and the telescopic net size of the two splints is 40mm-280mm, and when stretched, the two splints The opening force of each splint is ≤300N; it should be noted that when 25 cigarettes are loaded under normal conditions, the upper and lower dimensions of the box are 250mm. Considering that the equipment needs to be configured on the automatic loading device, the upper and lower opening distance of the box needs to be More than 250mm, theoretically at least 280mm; at the same time, the opening force of the upper and lower plastic plates is ≤300N, otherwise it is easy to get stuck on the packaging machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com