Portable platform for tower crane bracket welding

A tower crane and platform technology, applied in the field of portable platforms, can solve problems such as lack of wide applicability, embedded parts cannot be turned around, and high cost investment, and achieve the effects of convenient transportation and turnaround, low cost of use, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

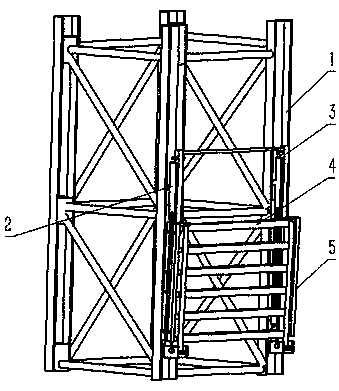

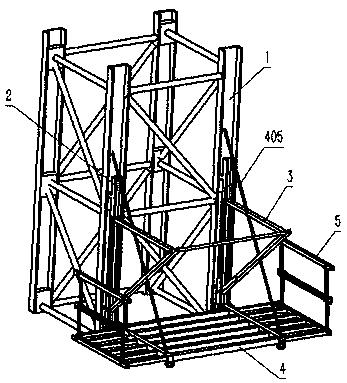

[0045] see Figure 1 to Figure 10 As shown, the present invention is a portable platform for tower crane corbel welding, comprising a hanging rod mechanism 2 hung on the tower crane 1, the hanging rod mechanism 2 is connected with an installation protection mechanism 3 and a platform mechanism 4, and the platform mechanism 4 Construction protection mechanism 5 is provided on both sides.

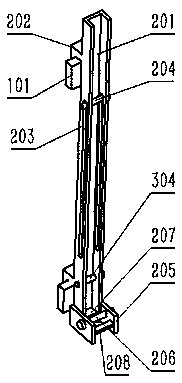

[0046] The hanging rod mechanism 2 includes two symmetrical and parallel slide rails 201, and each slide rail 201 is provided with hooks 202 on the upper and lower sides of the back, and each hook 202 is set corresponding to the climbing support block 101 on the standard section of the tower crane 1. Both sides of the slide rail 201 are symmetrical and are provided with through slide slots 203 from top to bottom. A first pin 204 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com