Preparation method for high calcium aluminium alloy, and high calcium aluminium alloy

An aluminum alloy and high-calcium technology, applied in the preparation of high-calcium aluminum alloys and high-calcium aluminum alloys, can solve the problems of low steelmaking efficiency, influence of desulfurization, and slow slag formation, so as to improve steelmaking efficiency and reduce The effect of fast pollution and slag formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

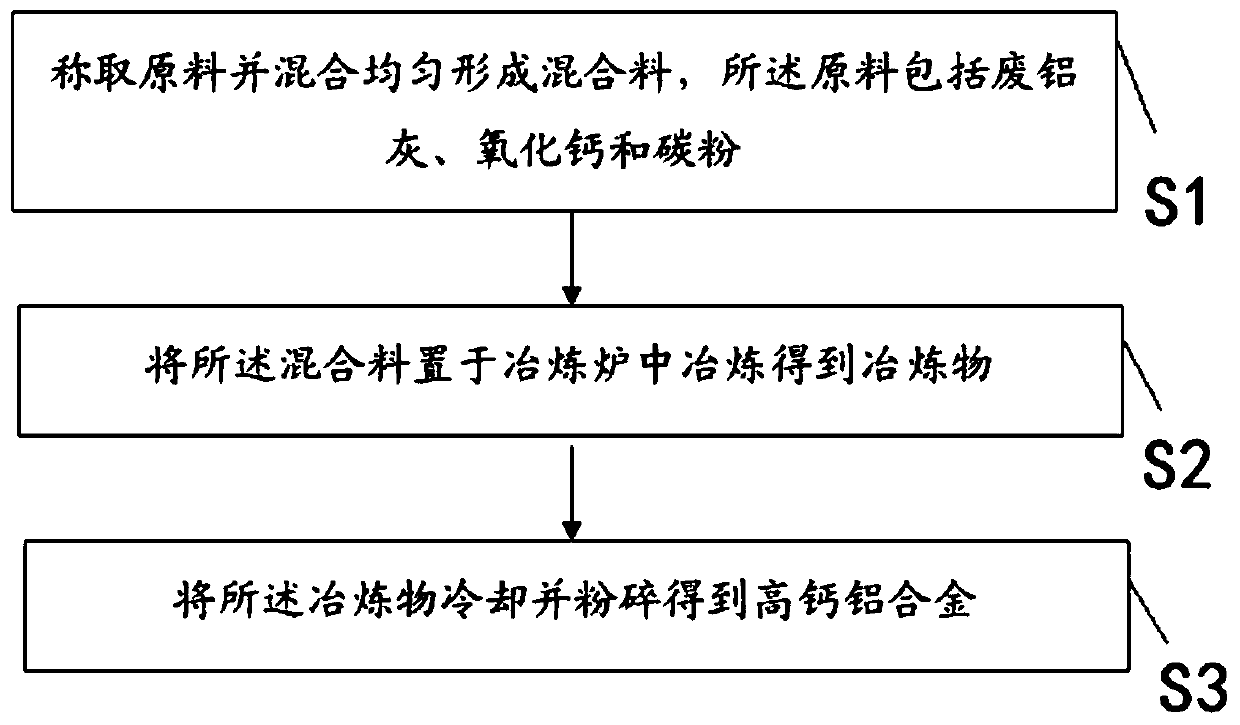

[0032] Such as figure 1 As shown, the preparation method of the high-calcium aluminum alloy according to the embodiment of the present invention includes:

[0033] Step S1, weighing raw materials and mixing them uniformly to form a mixture, the raw materials include waste aluminum ash, calcium oxide and carbon powder;

[0034] Step S2, smelting the mixture in a smelting furnace to obtain a smelted product;

[0035] Step S3, cooling and pulverizing the smelted product to obtain a high-calcium aluminum alloy.

[0036] That is to say, first weigh the raw materials and mix them uniformly to form a mixture. The raw materials can be mixed evenly by stirring in a mixing container. The raw materials include waste aluminum ash, calcium oxide and carbon powder. Waste slag and waste aluminum ash mainly contain alumina, a small amount of aluminum and a small amount of impurities; the mixture is smelted in a smelting furnace to obtain smelted products. The smelting furnace can be an elec...

Embodiment 1

[0047] The raw materials are weighed and mixed uniformly to form a mixture, the raw materials include 60 parts by weight of waste aluminum ash, 45 parts by weight of calcium oxide and 10 parts by weight of carbon powder;

[0048] The mixture is placed in an electric arc furnace, and the mixture is smelted at 1480°C for 2.5 hours to obtain a smelted product;

[0049] The smelted product is cooled and crushed to obtain a high-calcium aluminum alloy, the specific gravity of aluminum is 40%, and the specific gravity of calcium is 20%.

Embodiment 2

[0051] Weighing the raw materials and mixing them uniformly to form a mixture, the raw materials include 80 parts by weight of waste aluminum ash, 30 parts by weight of calcium oxide and 5 parts by weight of carbon powder;

[0052] The mixture is placed in an electric arc furnace, and the mixture is smelted at 1520°C for 2 hours to obtain a smelted product;

[0053] The smelted product is cooled and pulverized to obtain a high-calcium aluminum alloy, the specific gravity of aluminum is 60%, and the specific gravity of calcium is 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com