Method for extracting and separating arsenic and iron in chloride system

A chloride and extraction technology, which is applied in the field of chemical solvent extraction, can solve the problems of dangerous solid waste containing arsenic, difficulty in effectively separating arsenic and iron, etc., and achieve the effects of low consumption of chemical reagents, low cost, and high recovery rate of arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 100mL containing As 3.0g / L, Fe 20g / L, H + 0.5mol / L, Cl - 7.0mol / L feed solution, and 50mL organic phase containing 20% isooctyl alcohol and 80% sulfonated kerosene, mixed in a separatory funnel at 30°C for 2min, then allowed to stand for clarification and phase separation; after releasing the raffinate , mix the arsenic-loaded organic phase with 50 mL of 0.5 mol / L hydrochloric acid aqueous solution at 30°C for 10 minutes, then let stand to clarify and separate the phases, release the stripping liquid, and return the blank organic phase after stripping to the extraction process for recycling.

[0028] The raffinate obtained after extraction contains As 0.34g / L and Fe 19g / L; the strip obtained after stripping contains As4.7g / L and Fe 1.9g / L.

Embodiment 2

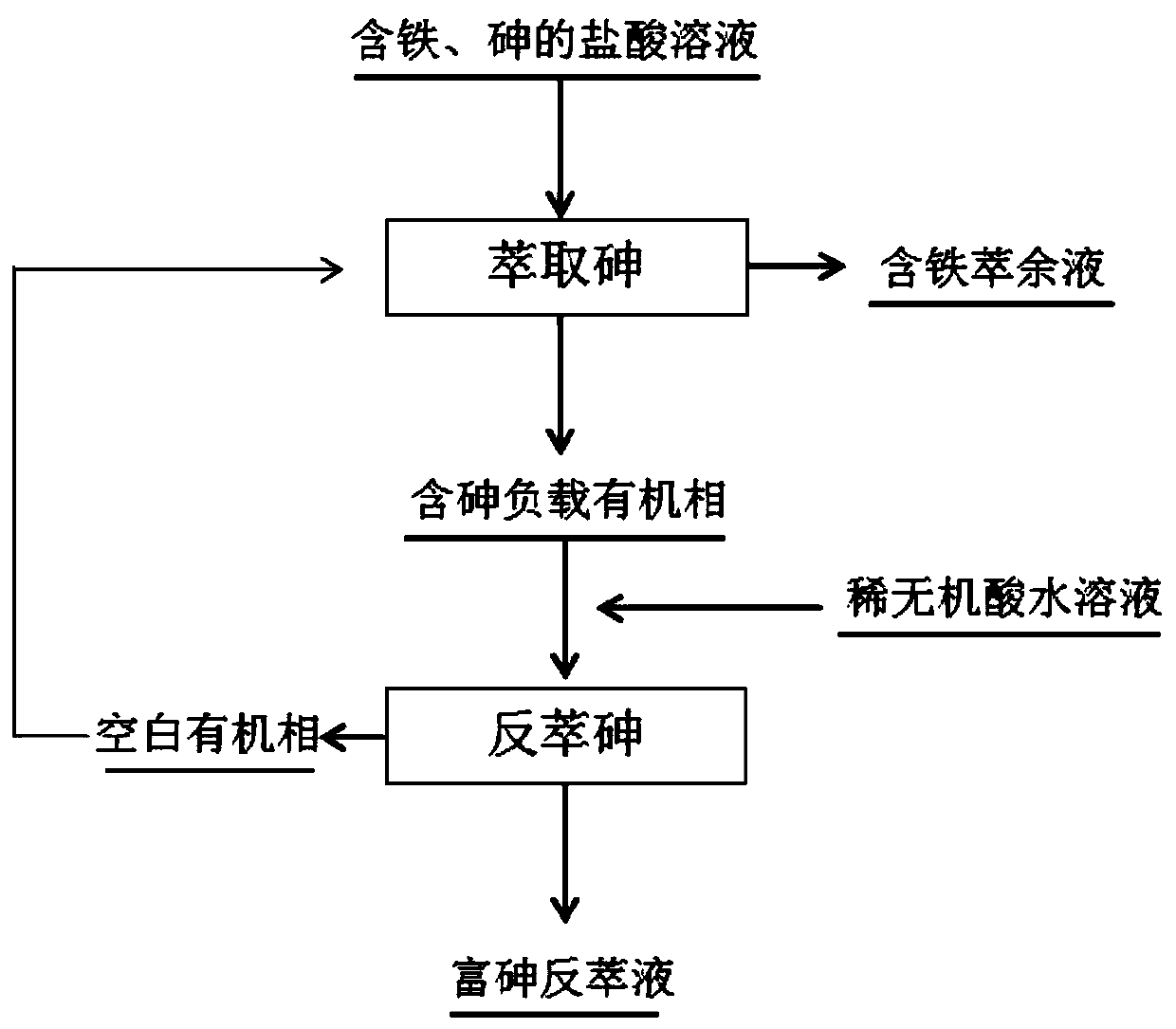

[0030] The invention provides a method for extracting and separating arsenic and iron in a chloride system, such as figure 1 shown, including the following steps:

[0031] (1) Extract arsenic: extract As 3.0g / L, Fe 20g / L, H + 0.5mol / L, Cl - 7.0mol / L feed solution, and the organic phase containing 20% isooctyl alcohol and 80% sulfonated kerosene, after carrying out 3-stage countercurrent extraction under the conditions of 30°C, a phase ratio of 1 / 2, and a contact time of 2min, the extracted The remaining liquid is released;

[0032] (2) Back-extraction of arsenic: after three-stage countercurrent back-extraction of the arsenic-containing organic phase and 0.5mol / L hydrochloric acid aqueous solution at 30°C, a ratio of 1 / 1, and a contact time of 10 minutes, the back-extraction liquid release;

[0033] (3) The blank organic phase after stripping is returned to the extraction process for recycling.

[0034] The raffinate obtained after three-stage countercurrent extraction ...

Embodiment 3

[0036] Take 100mL containing As 2.6g / L, Fe 18g / L, H + 3.0mol / L, Cl - 6.0mol / L feed solution, and 300mL organic phase containing 5% 2-octanol and 95% sulfonated kerosene, mixed in a separatory funnel at 30°C for 10min, then allowed to stand for clarification and phase separation; , mix the arsenic-containing organic phase with 60 mL of 2.0 mol / L sulfuric acid aqueous solution at 30°C for 5 minutes, then let it stand for clarification and separate the phases. After releasing the stripping liquid, return the blank organic phase after stripping to the extraction process for recycling.

[0037] The raffinate obtained after extraction contains As 0.39g / L and Fe 17.4g / L; the strip obtained after stripping contains As3.4g / L and Fe 0.94g / L.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap