Patents

Literature

90 results about "Octyl Alcohols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

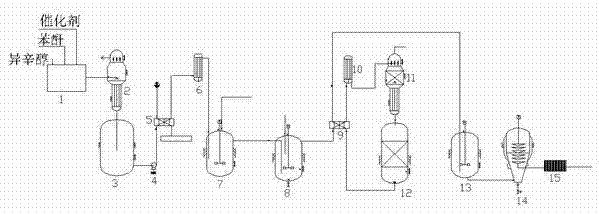

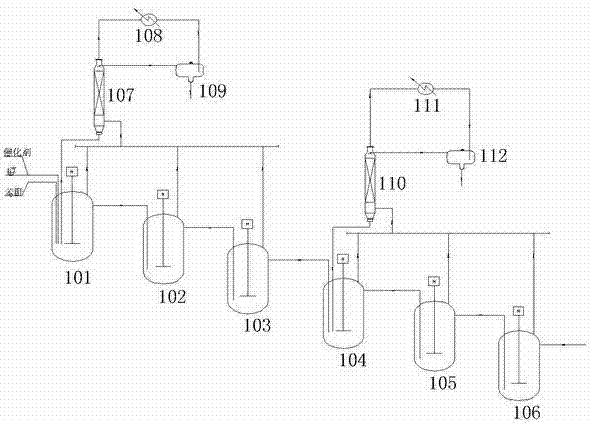

A kind of dop continuous production process and used equipment

InactiveCN102295564AReduce energy consumptionImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationChemistryTransformation ratio

The invention relates to a continuous production process for DOP (Dioctyl Phthalate) and used equipment, which belong to the technical field of fine chemical production. The continuous production process comprises the following steps of: firstly carrying out esterification reaction of phthalic anhydride and isooctyl alcohol in the presence of a catalyst such as titanate, and then carrying out dealcoholization, neutralization and water washing, steam stripping and drying, adsorption and filtration to obtain the DOP. In the invention, by adopting six esterification kettles which are connected in series and have completely the same structure for the esterification reaction, alcohol is kept excessive, the conversion rate is high and is larger than 99.5 percent, the acid value of coarse ester generated in the reaction is less than or equal to 0.3mgKOH / g, and the excessive alcohol accounts for 16 percent; by using the equipment, a production method with low energy consumption, high production capacity and continuous esterification is obtained, the conversion rate is high, the production quantity of a device is improved, the production cost is lowered, and the continuous production process is suitable for industrialized production; the excessive alcohol and the water generated in an esterification stage are recycled and comprehensively recovered, so that the generation of three wastes is reduced; and the production capacity of the DOP is enlarged by 50 percent as compared with a single set of domestic device, and the consumption of energy sources is decreased by 20 percent.

Owner:浙江庆安化工有限公司

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

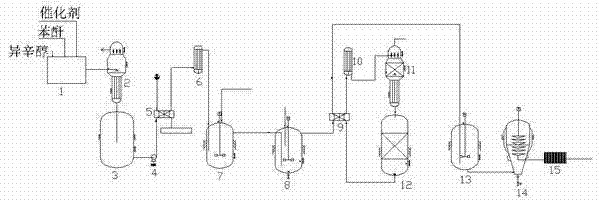

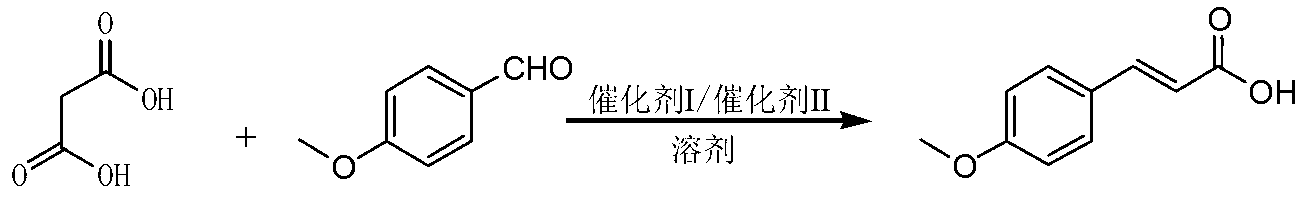

Preparation method of sun-screening agent iso-octyl p-methoxycinnamate

ActiveCN103242163AAchieve separationIncrease profitOrganic compound preparationCarboxylic acid esters preparationWater insolubleSolvent

The invention relates to a preparation method of a sun-screening agent OMC (iso-octyl P-Methoxycinnamate). The preparation method comprises the following steps of: 1, adding p-anisaldehyde, malonic acid, a catalyst I organic secondary amine substance, a catalyst II organic acid substance and a water-insoluble organic aromatic hydrocarbon solvent to a condensation reaction kettle, and carrying out reflux water diversion reaction for 4-5 hours; 2, after condensation reaction is finished, cooling to 5-15 DEG C, filtering to obtain a p-methoxycinnamic acid crude product, directly applying filter liquor to next reaction, and optionally supplementing a small quantity of catalysts and solvents to the filter liquor; 3, adding catalyst III macroporous type storng acid cation exchange resin, isooctyl alcohol, the p-methoxycinnamic acid crude product and an aromatic hydrocarbon or aliphatic hydrocarbon solvent to an esterifying reaction kettle, and carrying out reflux water diversion reaction for 2-3 hours; and 4, after esterifying reaction is finished, cooling to 65 DEG C, filtering and recovering the catalysts for mechanical application, washing the filter liquor to neutrality through a 5% sodium carbonate water solution, desolventizing, and rectifying to obtain the final product isooctyl p-methoxycinnamate. The method disclosed by the invention has the characteristics of easiness, convenience, easiness in control, industrial production, low environment pollution, low energy consumption, material recycling, high product purity, and the like.

Owner:ANHUI SHENGNUOBEI CHEM TECH

Preparation method of ultrahigh-purity niobium oxide and prepared ultrahigh-purity niobium oxide

ActiveCN104445406AEasy to separateProcess technology is stableNiobium compoundsPhysical chemistryPickling Agents

The invention discloses a preparation method of ultrahigh-purity niobium oxide. The preparation method comprises the steps of acidity regulation, extraction separation, neutralization, precipitation, drying and calcining by taking a fluoroniobic acid solution as a raw material. In the extraction separation step, sec-octyl alcohol is used for extracting the regulated niflumic acid material liquid to obtain an organic phase; subsequently the organic phase is pickled by a pickling agent; finally the pickled organic phase is re-extracted by an anti-niobium agent to obtain the ultrahigh-purity niobium oxide. The invention also provides the ultrahigh-purity niobium oxide prepared by the method; the percentage composition of Nb2O5 is larger than or equal to 99.995%; the content of each impurity satisfies the regulations of the standard YS / T548-2007 on product grades F Nb2O5-048 and F Nb2O5-045.

Owner:JIUJIANG TANBRE

Extraction method of lincomycin

ActiveCN103724380AHigh strengthExtended service lifeSugar derivativesSugar derivatives preparationChemical oxygen demandUltrafiltration

The invention provides an extraction method of lincomycin. The extraction method mainly comprises the following steps: adjusting acidity of fermentation liquor, filtering by using a ceramic ultrafiltration membrane, then adjusting alkalinity, then filtering by using a ceramic ultrafiltration membrane again, then carrying out primary sec-octyl alcohol extraction and hydrochloric acid back-extraction, adjusting alkalinity of the primary back extraction liquor and then filtering by using a ceramic ultrafiltration membrane again; carrying out secondary sec-octyl alcohol extraction and hydrochloric acid back-extraction and adding acetone to the secondary back extraction liquor to carry out evaporative crystallization. According to the extraction method provided by the invention, the yield of the lincomycin is high, the color grade of the lincomycin can be improved, and the B component content in the lincomycin is reduced. According to the extraction method of the lincomycin, the feed liquid quality of other extraction technologies can be improved by a membrane treatment process, the integral extraction efficiency is further improved, the residual volume of sec-octyl in raffinate in the extraction procedure is reduced, the product quality is improved, and meanwhile, the COD (Chemical Oxygen Demand) in produced wastewater is reduced. The extraction method has certain economic benefit and environmental benefit.

Owner:JIANGSU JIUWU HITECH

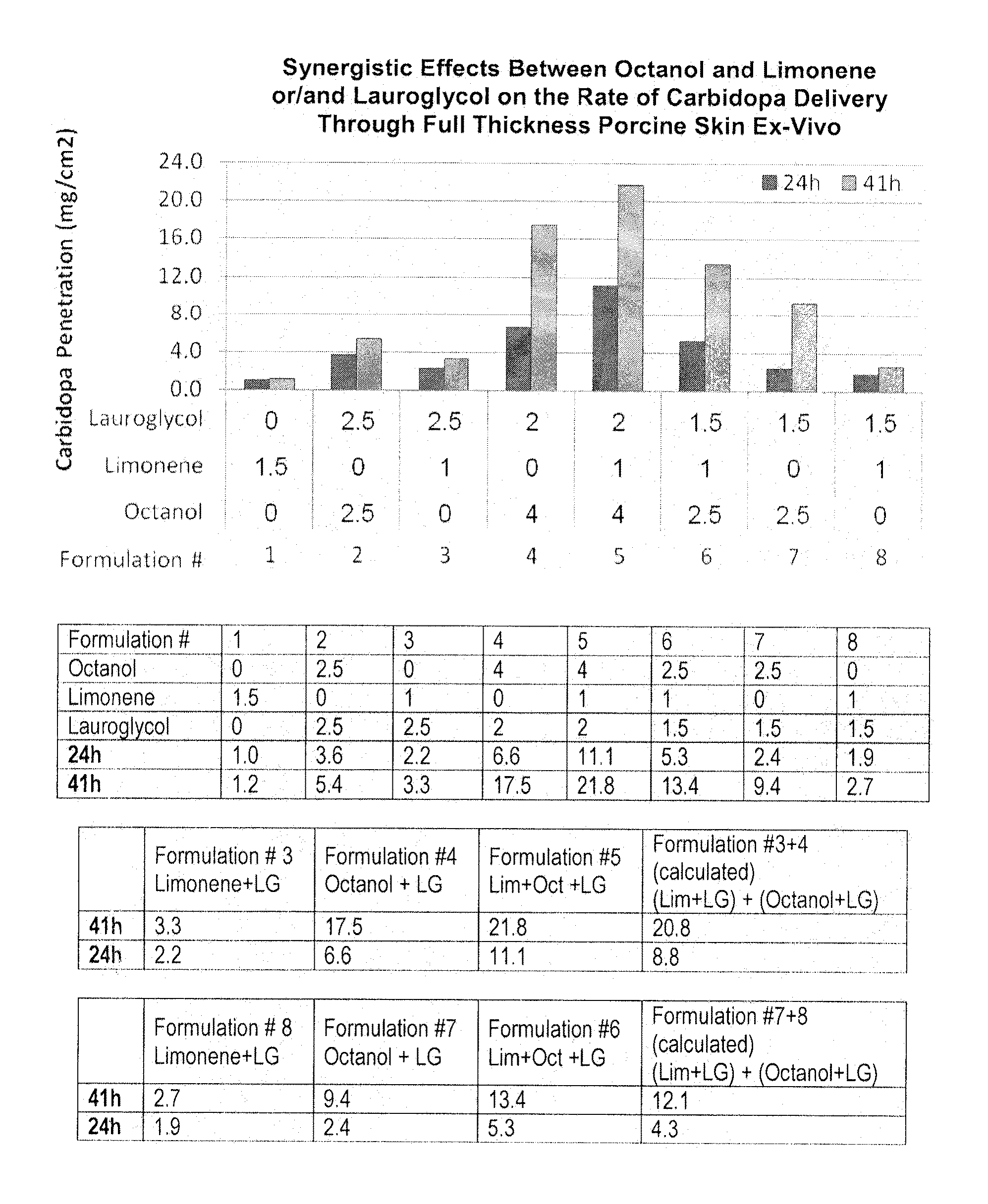

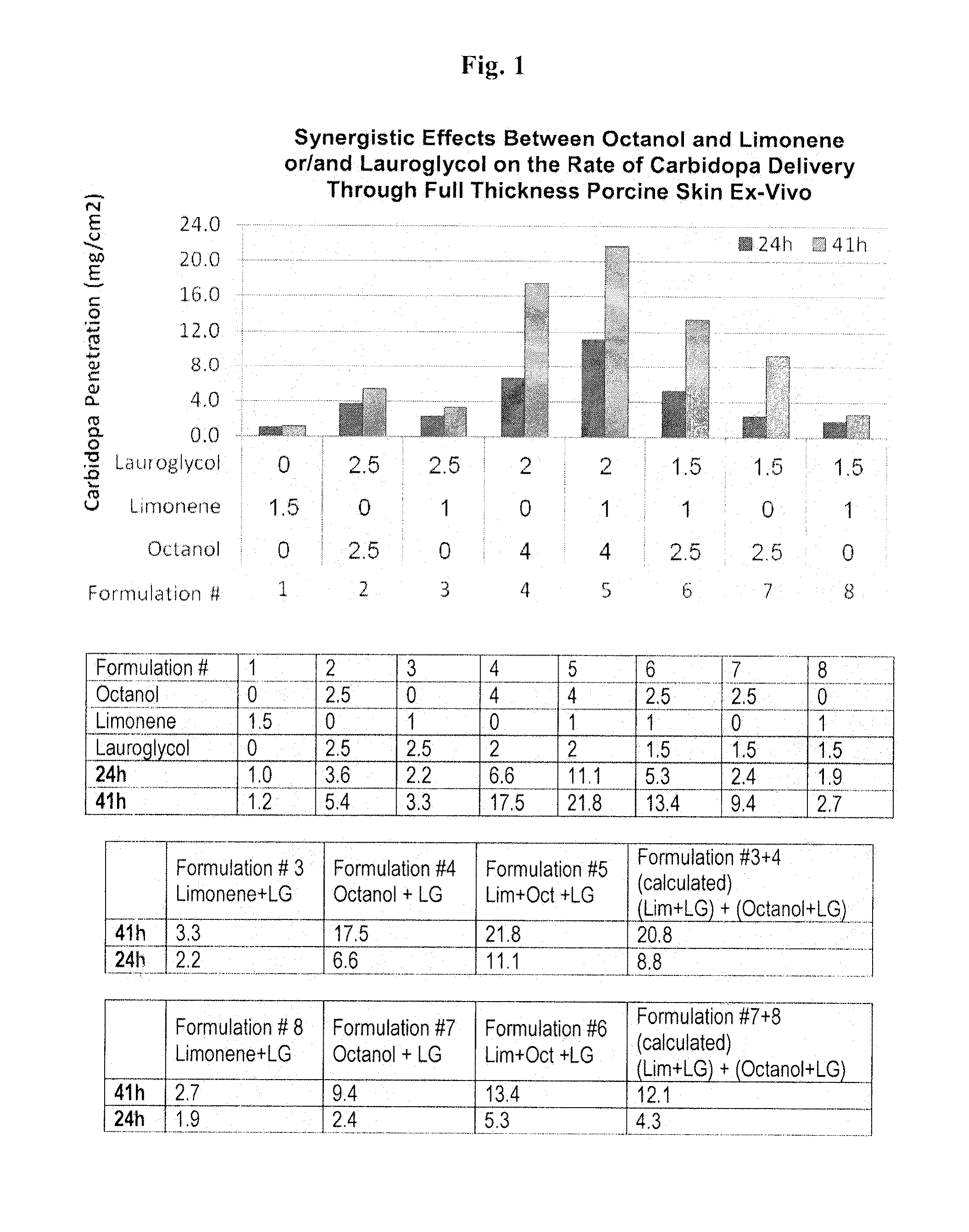

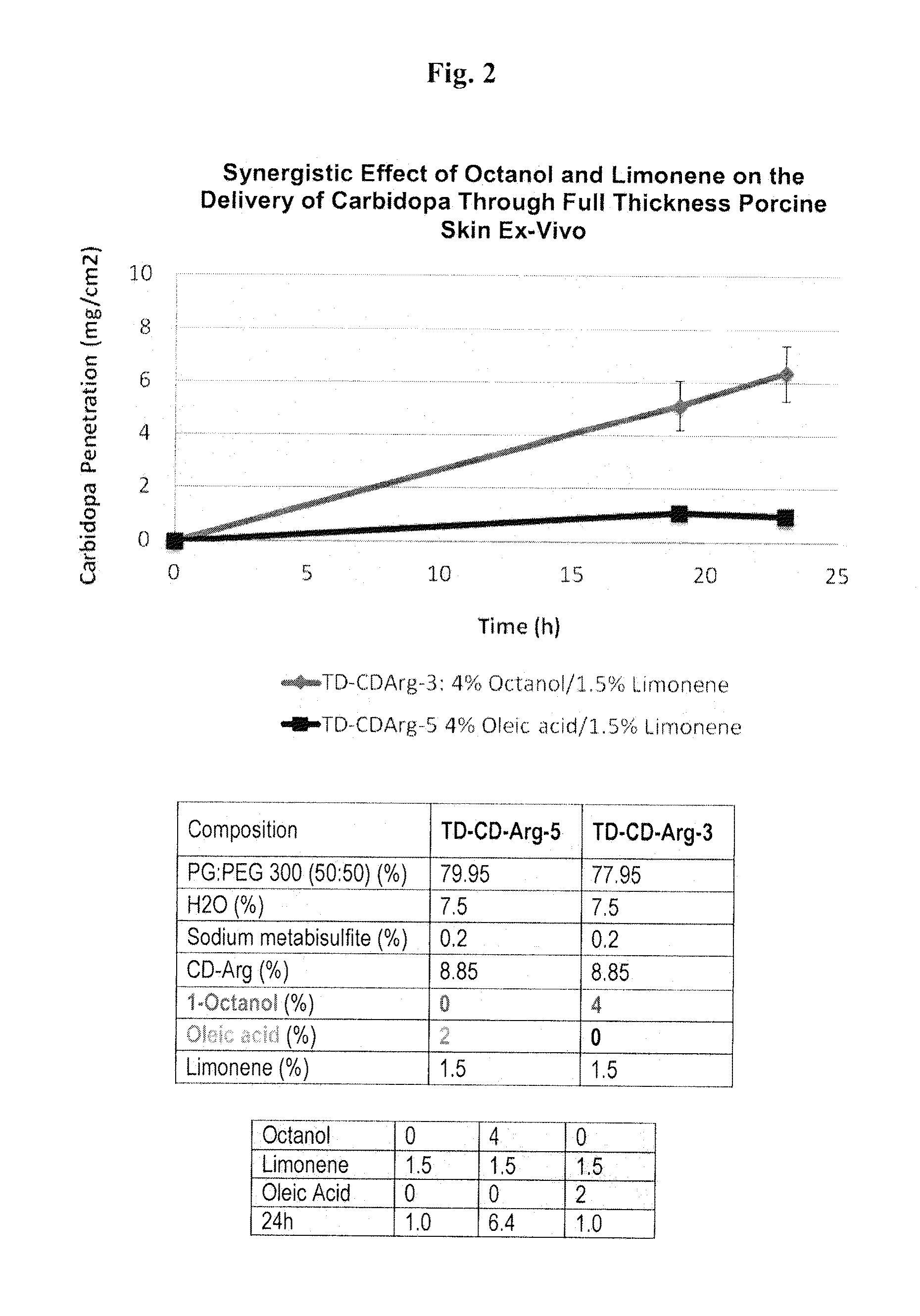

Compositions for transdermal delivery of active agents

Disclosed herein are compositions that are useful in effecting the transdermal delivery of therapeutic agents. More particularly, the disclosed transdermal compositions may include a fatty alcohol (for example, octanol), a terpene (for example, limonene), and an active agent comprising an amine moiety.

Owner:NEURODERM

Porcelain imitating paint

InactiveCN1603368AShorten the construction periodHigh hardnessCoatingsSodium BentonitePolyvinyl alcohol

One kind imitates the porcelain coating, is by the polyvinyl alcohol, the calcium carbonate powder, the talcum powder, the ash calcium powder, the wollastonite powder, the bentonite, the zinc mellow, the ethylol cellulose, Op-10, the dibutyl ester, the toluene, the urea, Tp-1 guards against sinks the medicinal preparation, the water mix is made, the degree of hardness high, the smooth finish good, bears scours, the product storage time long, the ventilation moisture-proof, the service life long, the application scope is broad, may cause the architectural engineering to reduce the time limit for a project.

Owner:长春恩维物贸有限责任公司

Process for preparing n-hexylic acid by oxidation of sec- octyl alcohol with nitric acid and its special device

InactiveCN1699324AReduce NO contentReduce processing workloadCarboxylic preparation by oxidationImpurityNitric acid

The disclosed method includes a capryl alcohol oxidation step and a crude oxidation liquid purification step, wherein in the capryl alcohol oxidation step, a downward injection type reactor is employed to use the closed injection cycle of the reaction liquid for charging nitric acid, air and nitroxides gases produced in the reaction into the reactor for mixing and reacting with capryl alcohol, in the crude oxidation liquid purification step, a non-washing physical method, i.e. an air blowing method is employed to remove the inorganic acidic impurity in the oxidation liquid, the processing time being 0.5-2.0 hours.

Owner:HENAN UNIVERSITY

A kind of extraction method of lincomycin

ActiveCN103724380BHigh strengthExtended service lifeSugar derivativesSugar derivatives preparationBiotechnologyChemical oxygen demand

The invention provides an extraction method of lincomycin. The extraction method mainly comprises the following steps: adjusting acidity of fermentation liquor, filtering by using a ceramic ultrafiltration membrane, then adjusting alkalinity, then filtering by using a ceramic ultrafiltration membrane again, then carrying out primary sec-octyl alcohol extraction and hydrochloric acid back-extraction, adjusting alkalinity of the primary back extraction liquor and then filtering by using a ceramic ultrafiltration membrane again; carrying out secondary sec-octyl alcohol extraction and hydrochloric acid back-extraction and adding acetone to the secondary back extraction liquor to carry out evaporative crystallization. According to the extraction method provided by the invention, the yield of the lincomycin is high, the color grade of the lincomycin can be improved, and the B component content in the lincomycin is reduced. According to the extraction method of the lincomycin, the feed liquid quality of other extraction technologies can be improved by a membrane treatment process, the integral extraction efficiency is further improved, the residual volume of sec-octyl in raffinate in the extraction procedure is reduced, the product quality is improved, and meanwhile, the COD (Chemical Oxygen Demand) in produced wastewater is reduced. The extraction method has certain economic benefit and environmental benefit.

Owner:JIANGSU JIUWU HITECH

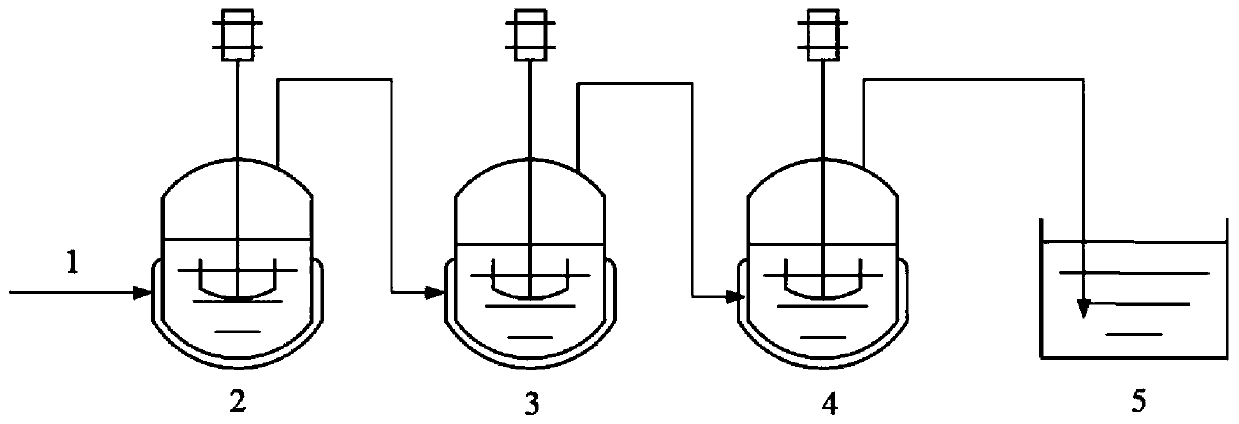

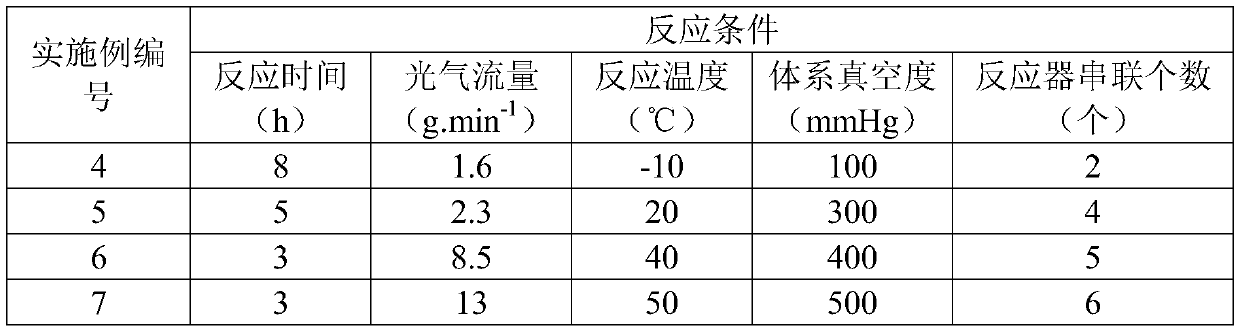

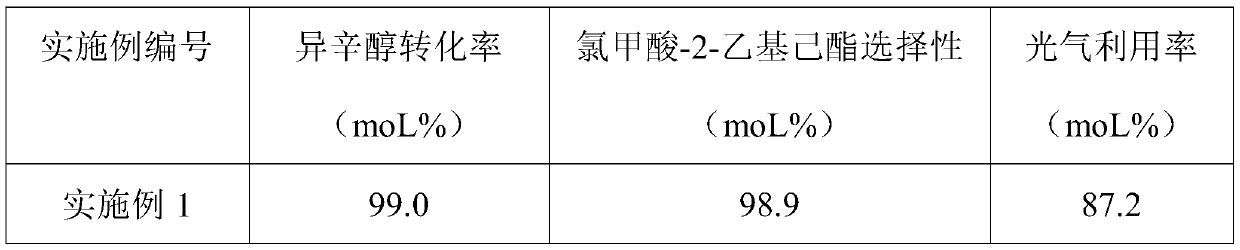

Method for preparing 2-ethylhexyl chloroformate

PendingCN111302941AIncrease profitTransfer in timeChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesIsooctyl alcoholEthyl group

The invention provides a method for preparing 2-ethylhexyl chloroformate. The method comprises a step of reacting isooctyl alcohol with phosgene by using multiple stages of reaction kettles which areconnected in series. By adopting a micro-negative pressure system, hydrogen chloride generated by the reaction can be transferred in time, and unreacted phosgene in one reaction kettle can enter the next-stage reaction kettle for further reaction, so the utilization rate of phosgene and the conversion rate of isooctyl alcohol are improved, reaction time is greatly shortened, and industrial application value is relatively high.

Owner:JIANGSU YANGNONG CHEM GROUP +3

Method for removing ethanol, isopropanol and octyl alcohol from amino resin workshop wastewater

InactiveCN105084495AStrong complexing abilityFast precipitationWater contaminantsNature of treatment waterOctanolAcetophenone

The invention relates to a method for removing ethanol, isopropanol and octyl alcohol from amino resin workshop wastewater. The components adopted by the method comprises 1,3,3-trimethyl-2-oxabicyclo[2.2.2]octane, 1,8-dihydroxy-3-methoxy-6-methylanthraquinone, S(-)-2-amino-6-n-propyle-4,5,6,7-tetrahydrobenzothiazole dihydrochloride, 4-octylphenol ethoxylate, 3',4'-dihydoxy-2-(methylamino)acetophenone hydrochloride, 4-acetoxy-3-methoxy-(2-propenyl) benzene, 4-methoxybenzyl acetate, 6,6,10-trimethyl bicyclo-3,1,1-hept-2-ene, and 2-[[1-(3-acetylthio-2-methylpropionyl)pyrrolidine-2-formyl]amino]-3-phenylpropionic acid. The components adopted by the method have strong complexing capability with target substances, high speed of forming complex precipitates, and high removal rate up to 99.9%.

Owner:李海兰

Mite-prevention and mildew-proof disinfector for air conditioner and preparation method of mite-prevention and mildew-proof disinfector

ActiveCN103666832AImprove solubilityClean up thoroughlySurface-active detergent compositionsDetergent compounding agentsBiotechnologyDiethylene glycol monobutyl ether

The invention provides a mite-prevention and mildew-proof disinfector for an air conditioner and a preparation method of the mite-prevention and mildew-proof disinfector. The disinfector comprises the following raw materials: R-301, sec-octyl alcohol polyoxyethylene (5-6) ether, a non-ionic surfactant, diethylene glycol monobutyl ether, didoctyl dimethyl ammonium chloride, lemon essential oil and alcohol. The disinfector can permeate and be dispersed to an evaporator and an air supply system of the air conditioner rapidly, dissolves dirt quickly and completely, washes deeply, removes bacteria and viruses thoroughly, prevents an air-condition disease, automatically generates a washing and sterilization film in the evaporator and the air supply system, and can sterilize, and prevent mites and mildew continuously. The disinfector further comprises the lemon essential oil, so that light lemon fragrance can be reserved during cleaning of the air conditioner, and an environment is fresher and more pleasant.

Owner:上海绿伞环保科技发展有限公司

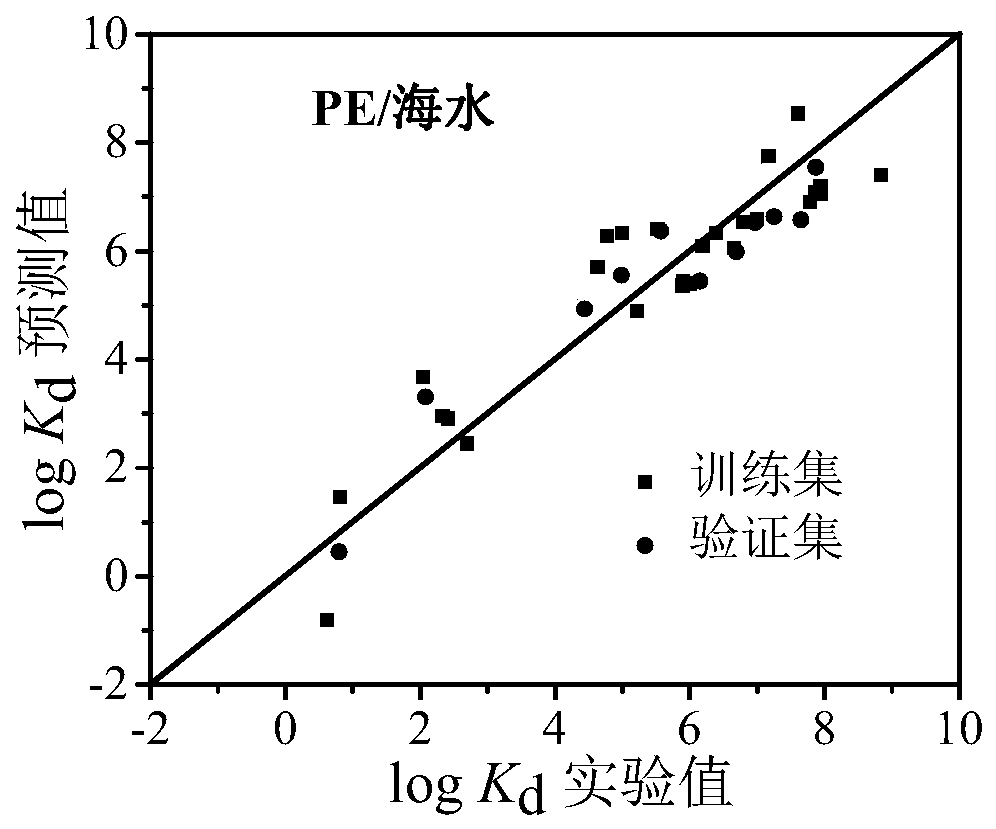

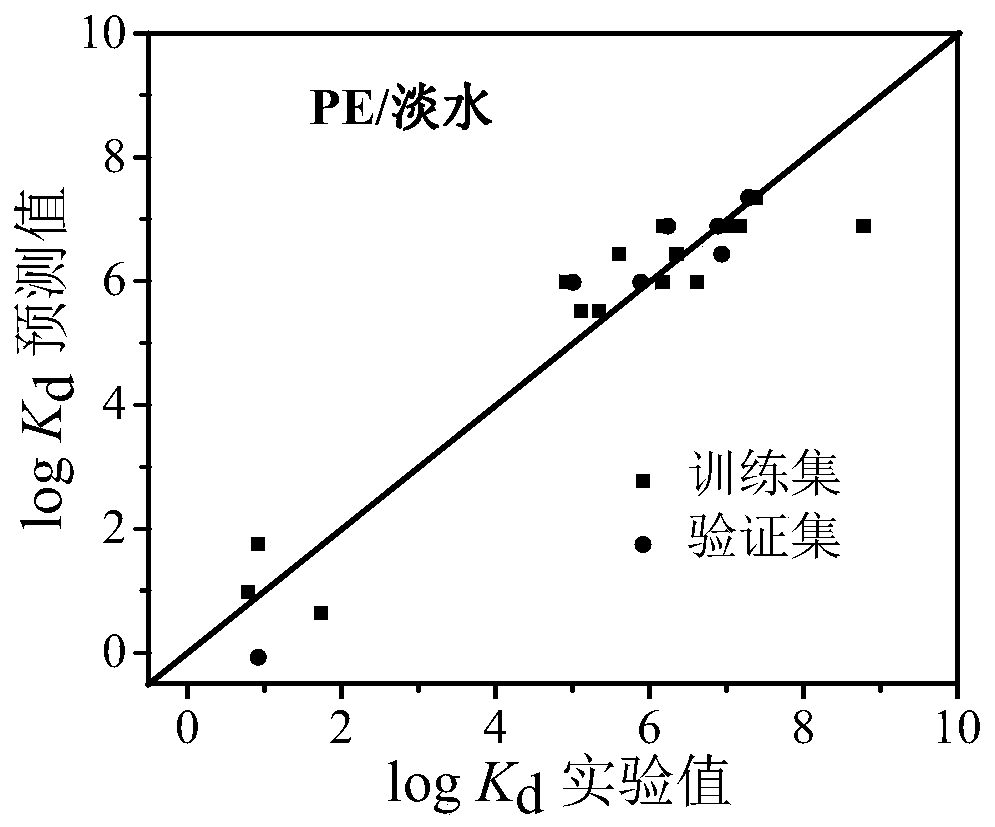

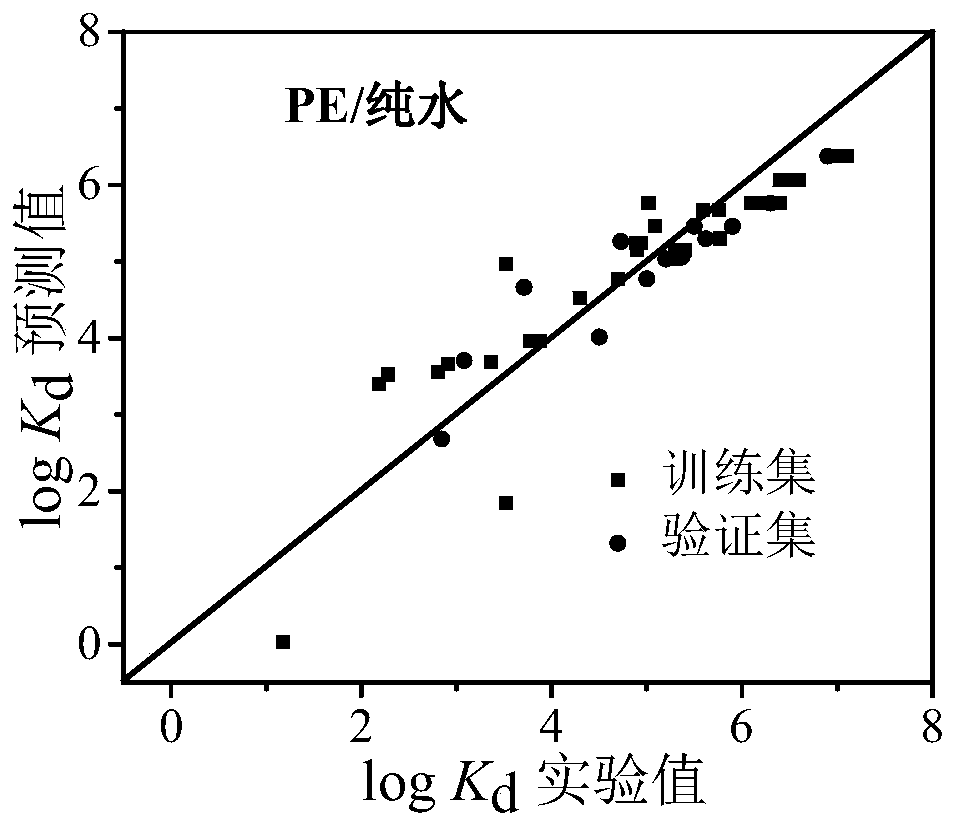

Method for predicting distribution equilibrium constant of organic pollutants between polyethylene type micro-plastics and water phase

ActiveCN111402962AImprove applicabilityEasy to getChemical property predictionGeneral water supply conservationMolecular orbital energyChlorobenzene

The invention provides a method for predicting a distribution equilibrium constant of organic pollutants between polyethylene type micro-plastics and a water phase, belonging to the technical field ofquantitative structure-property relations for environmental ecological risk evaluation. According to the method, descriptors including epsilon<alpha> (wherein epsilon<alpha> = E<LUMO> - E<HOMO-water>, E<LUMO> is the lowest unoccupied molecular orbital energy and E<HOMO> is the highest occupied molecular orbital energy), epsilon<beta> (wherein epsilon<beta> = E<HOMO-water> - E<LUMO>) and log D (n-octyl alcohol / water distribution coefficients under different pH conditions) are used for constructing QSPR models which can be used for predicting K<d> values of organic pollutants between PE and seawater, between PE and fresh water and between PE and pure water respectively. The established models can be used for predicting the K<d> values of organic pollutants such as polychlorinated biphenyl,chlorobenzene, polycyclic aromatic hydrocarbon, antibiotics, aromatic hydrocarbon, aliphatic hydrocarbon, hexachlorocyclohexane and the like, and have good fitting capability, prediction capability and robustness.

Owner:ZHEJIANG NORMAL UNIVERSITY

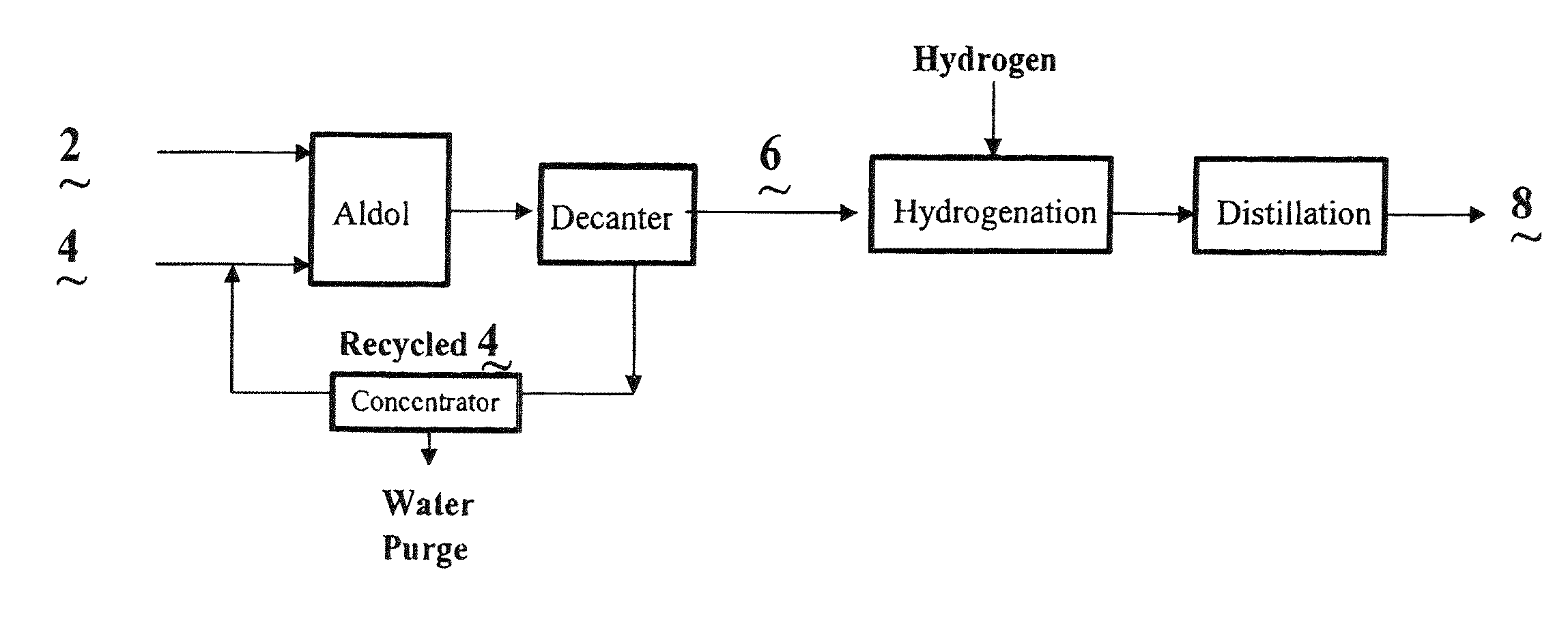

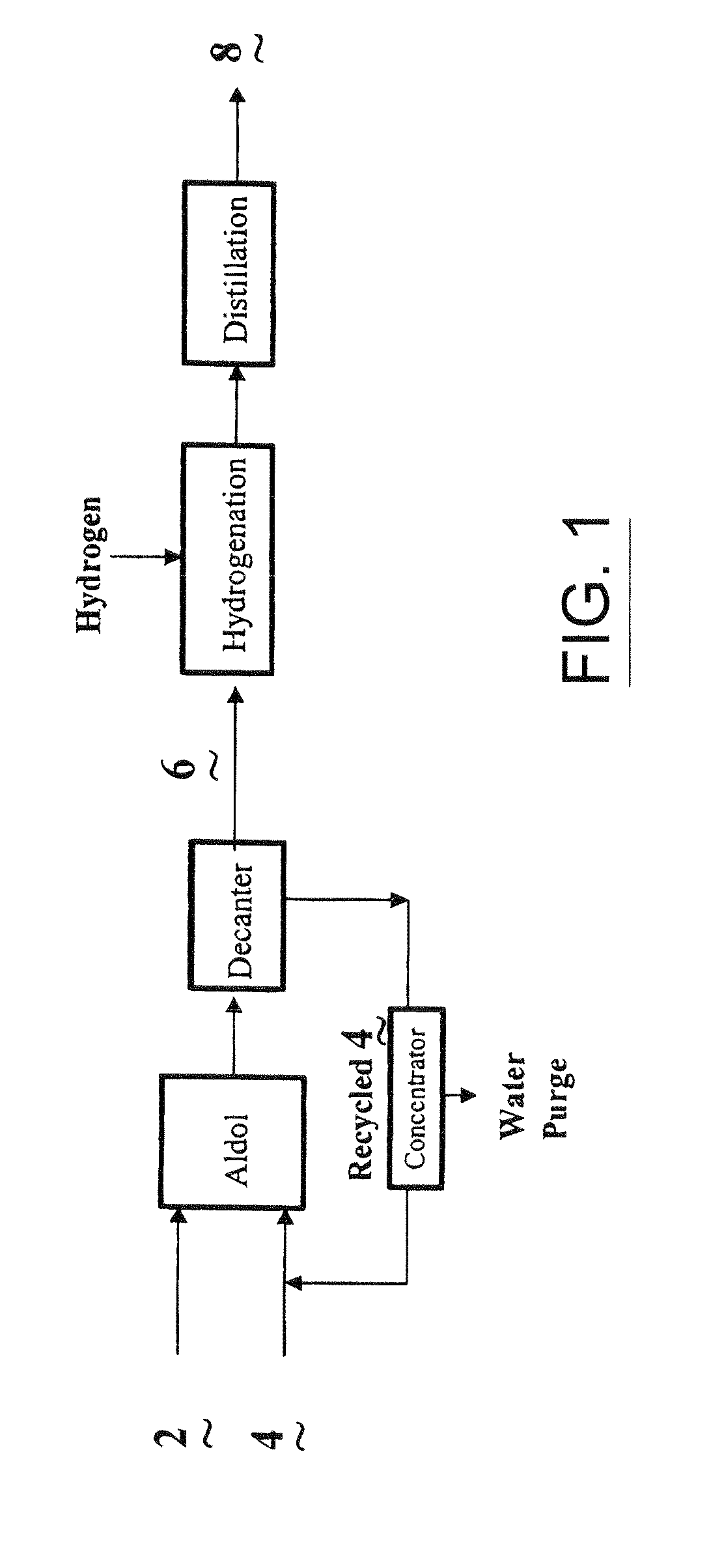

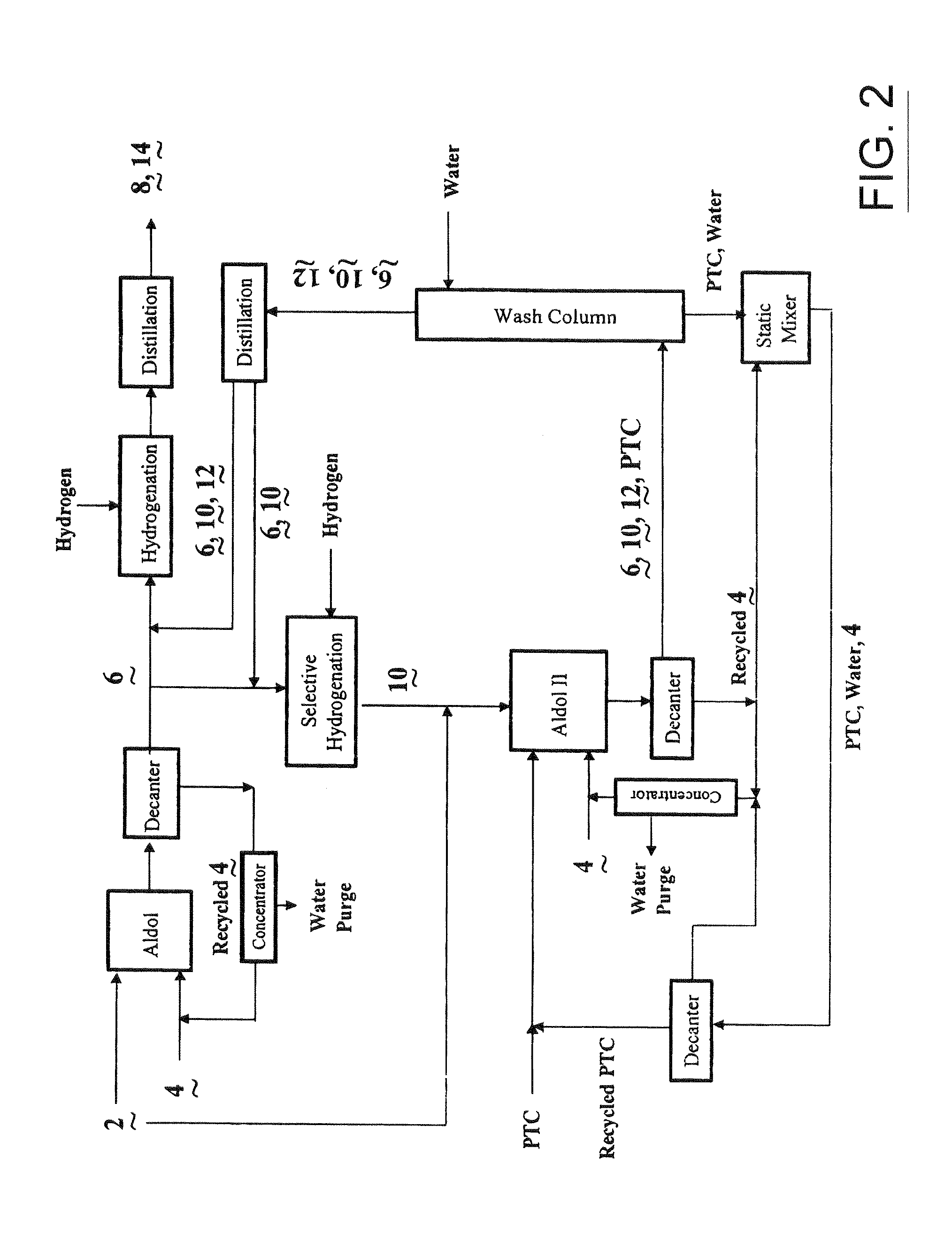

Process for the co-production of alcohols

InactiveUS20110046420A1Improve solubilityHigh selectivityOrganic compound preparationPreparation by hydrogenationPtru catalystBiochemical engineering

Owner:BASF CORP

Efficient fuel combustion-increasing agent

InactiveCN104694186AImprove protectionExtended service lifeLiquid carbonaceous fuelsIsooctyl alcoholSulfonate

The invention belongs to the technical field of fuel additives and particularly relates to an efficient fuel combustion-increasing agent. The efficient fuel combustion-increasing agent is characterized by being prepared from the following raw materials in parts by weight: 40-50 parts of butyl octadecenoate, 10-14 parts of polyether alcohol, 18-20 parts of isooctanol, 14-16 parts of fatty acid amide, 8-10 parts of triethylamine, 3-5 parts of di-iso-octyldiphenylamine, 1-3 parts of alkyl sodium sulfonate and 6-8 parts of methyl tertiary butyl ether. The efficient fuel combustion-increasing agent provided by the invention is prepared by the following steps: selecting the raw materials; then mixing according to a sequence of a formula; and quickly stirring for 3-6 minutes once one raw material is added. The efficient fuel combustion-increasing agent has the effects of saving energy, reducing emission, cleaning and increasing combustion.

Owner:张希顺

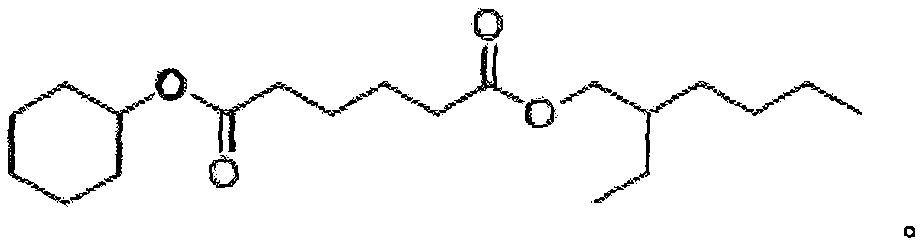

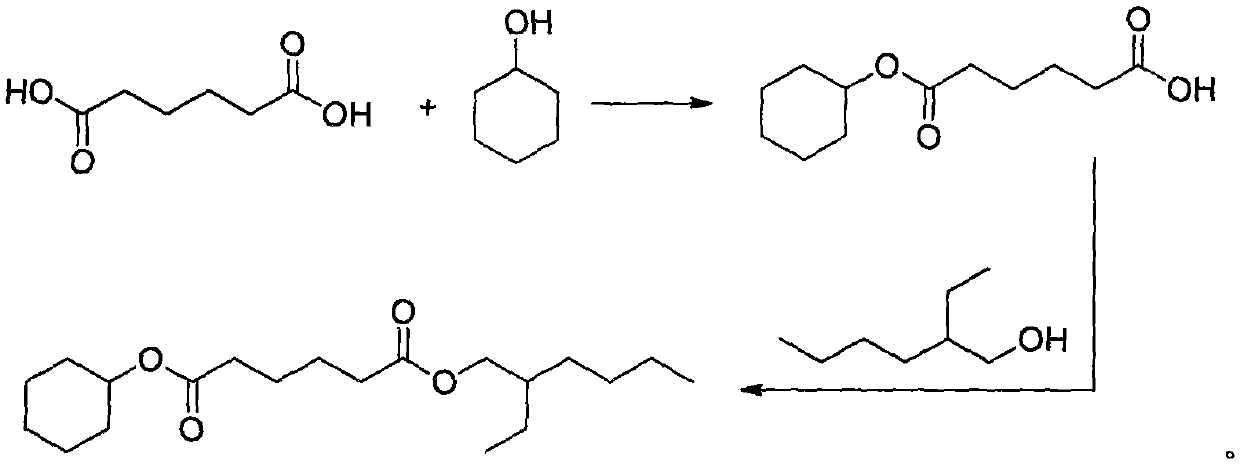

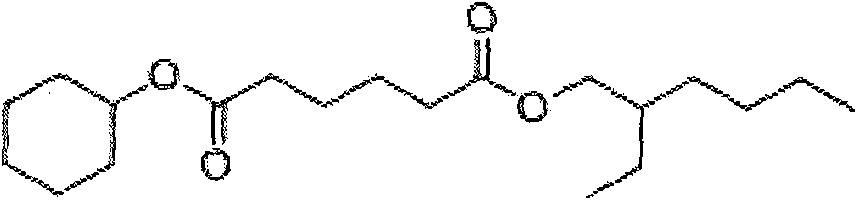

Asymmetric adipic acid cyclohexanol isooctyl alcohol ester and synthetic method and application thereof

InactiveCN105503589AGood plasticizing effectGood cold resistanceOrganic compound preparationCarboxylic acid esters preparationPlasticizerDistillation

The invention provides asymmetric adipic acid cyclohexanol isooctyl alcohol ester and a synthetic method and application thereof. The research is jointly funded by the science and technology fund project of Guizhou Provincial Science and Technology Bureau (Qian Ke He J Zi [2015] No. 2003) and the doctor fund project of Anshun University (asubsjj201501). The synthetic method specifically comprises the steps that a catalyst, a water-carrying agent, adipic acid and cyclohexanol are added into a reactor, and heating reflux is performed for water separation until no water is generated; isooctyl alcohol is added into the reactor, heating reflux is continued for water separation until no water is generated, and the mixture is cooled to room temperature; rotary evaporation is performed to remove the water-carrying agent; lastly, reduced pressure distillation is performed to obtain the asymmetric adipic acid cyclohexanol isooctyl alcohol ester. Being an environment-friendly plasticizer, the asymmetric adipic acid cyclohexanol isooctyl alcohol ester has the advantages that the plastification effect and cold resistance are good, and flexibility of a PVC product is good.

Owner:ANSHUN UNIV

Novel (1-sec-octyl, 2-tert-octyl)phthalate plasticizer and preparation method thereof

PendingCN109438229ASimple processLow costOrganic compound preparationCarboxylic acid esters separation/purificationPlasticizerOctanol

The invention relates to the technical field of production of plasticizers and discloses a novel (1-sec-octyl, 2-tert-octyl)phthalate plasticizer and a preparation method thereof. The (1-sec-octyl, 2-tert-octyl)phthalate plasticizer takes sec-octyl alcohol, phthalic acid and industrial ethyl hexanol as raw materials. The preparation method comprises the following steps: refining the sec-octyl alcohol, and carrying out a primary esterification reaction with phthalic acid to prepare a DCP monoester mixed solution; performing steam stripping dealcoholization to prepare a refined DCP monoester; adding the refined DCP monoester and the industrial ethyl hexanol into a secondary reactor, adding a catalyst, and carrying out a constant-temperature esterification reaction to obtain a DCOP diester mixed solution; finally, performing alkaline wash, steam stripping dealcoholization and actived carbon decoloration on the DCOP diester, thereby obtaining the novel (1-sec-octyl, 2-tert-octyl)phthalateplasticizer. The preparation method is simple in process, low in cost, high in yield, easy to control and capable of realizing large-scale production, and the prepared (1-sec-octyl, 2-tert-octyl)phthalate plasticizer is excellent in plasticizing effect and high in stability.

Owner:安阳市景晟科技有限公司

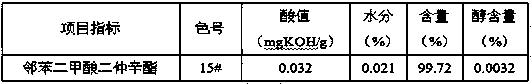

Preparation method of phthalate plasticizer

ActiveCN111517950AReduced neutralization washing stepsShorten production timeOrganic compound preparationCarboxylic acid esters preparationPlatinumPhthalic anhydride

The invention provides a preparation method of a phthalate plasticizer. The method specifically comprises the steps of esterification, crude dealcoholization, cooling, addition of a deacidifying agent, dealcoholization and filtration. The preparation method is adopted; treatment is carried out without a decolorizing agent, the chromaticity of the prepared phthalate plasticizer product can reach 10-15 # through platinum-cobalt standard colorimetry; phthalic anhydride and sec-octyl alcohol are used as raw materials; the acid value of the dioctyl phthalate prepared by the preparation method disclosed by the invention is less than or equal to 0.05 mgKOH / g; wherein the water content is less than or equal to 0.05%, the alcohol content is more than or equal to 99.5% and the alcohol content is less than or equal to 0.005%, and meanwhile, neutralizing and washing steps can be reduced, the wastewater amount is reduced, the alkali washing, washing and settling time is saved, the production cost is greatly reduced and the production benefit is increased.

Owner:山东元利科技有限公司

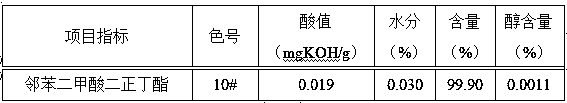

Synthesis method of high-content dihydroisojasmone spice

InactiveCN111302919AIncrease contentSimple stepsPreparation from heterocyclic compoundsFuranPtru catalyst

The invention belongs to the technical field of spice synthesis, in particular to a synthesis method of a high-content dihydroisojasmone spice. The synthesis method comprises the following steps: by taking 2-octanol as a solvent, di-tert-butyl peroxide as an initiator and boron acid as catalyst, enabling acrylic acid and 2-octanol to be subjected to a free radical addition reaction and a reflux reaction to separate out tert-butyl alcohol and water, performing reduced pressure distillation to realize recycling of 2-octanol, collecting 5-methyl-5-hexyl-2 (3H) furanone, and rearranging and dehydrating 5-methyl-5-hexyl-2 (3H) furanone molecules under the action of a solid acid catalyst by taking white oil as a solvent to synthesize a dihydroisojasmone spice product. The synthesis method provided by the invention has the advantages of relatively simple steps, no generation of acidic wastewater and relatively high total yield. In addition, through calculation, the content of dihydroisojasmone in the product synthesized by the synthesis method provided by the invention is up to 98% or above.

Owner:ANHUI HYEA AROMAS

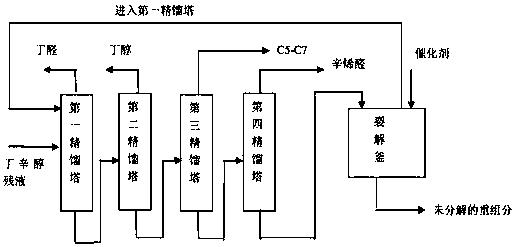

Novel method for recovering residual butyl alcohol-octyl alcohol

InactiveCN109384648AHigh isobutyraldehyde contentHigh purityOrganic compound preparationHydroxy compound preparationAlcoholOctanol

The invention provides a novel method for recovering residual butyl alcohol-octyl alcohol. According to the method, in a first rectifying tower (namely a butyraldehyde tower), butyraldehyde and butylalcohol are separated, at the same time, dehydration is carried out; butyl alcohol is extracted out from the top of a second rectifying tower, the purity of extracted butyl alcohol should be greater than 98 wt.%; all C5-C7 components such as butyl butyrate are extracted out from the top of a third rectifying tower; octyl alcohol and octenal are extracted out from the top of a fourth rectifying tower, and the purity of octyl alcohol is more than 98 wt.%.

Owner:乐陵齐青化工有限公司

Functional welding paste and preparation method thereof

ActiveCN103305123AHigh fracture mechanical propertiesImprove corrosion resistanceCoatingsO-Phosphoric AcidSalt spray test

The invention discloses a functional welding paste. The functional welding paste comprises the following components in percentage by mass: 3-40% of organic silicon resin containing double bonds, 20-40% of ethylene glycol monobutyl ether acetate, 1-10% of silicon dioxide, 10-20% of a leveling agent for a welding material, 0.3-5% of phosphoric acid, 1-5% of potassium persulfide, 10-20% of octyl alcohol, 1-4% of aluminum powder, 0.5-2% of hydrated magnesium silicate, 1-4% of calcium fluoride, 1-15% of titanium dioxide, 1-4% of calcium carbonate and 0.1-2% of cerium fluoride. The invention also discloses a preparation method of the functional welding paste. The fracture mechanical property strength of a welding joint of a weldment after using the functional welding paste can be up to 700MPa; the coating corrosion resistance can be up to 420h (salt spray test); the adhesive force is of grade 1 (one hundred grid test); and the Brinell hardness is 60HBW.

Owner:广东一三七化工科技有限公司

Methyl decyl lactone synthetic perfume normal pressure production method

The present invention provides a methyl decyl lactone synthetic perfume normal pressure production method, raw materials are easy to obtain, product yield is high, process conditions are mild, production cost is low, the process of production is free of environmental pollution, and the raw materials cause no production equipment corrosion. The method includes the following steps: a) stirring and mixing evenly acrylic acid, sec-octyl alcohol, initiator di-tertiary butyl peroxide and catalyst boric acid; b) adding the sec-octyl alcohol into a reaction kettle according to the dosage; c) dropwise adding the mixture obtained by the step a) into the reaction kettle for atmospheric pressure reaction; d) stirring at 100-200 DEG C for reaction for 2-5 hours; e) transferring reaction products into a water washing pot, adding clear water for layering, and separating the lower layer water phase; f) transferring upper layer organic phase reaction products to a kettle type distillation tower, heating, recycling the sec-octyl alcohol under vacuum; and g) transferring surplus reaction products into a kettle type rectification tower for fractionation to obtain methyl decyl lactone with the content of 99%.

Owner:ANHUI HYEA AROMAS

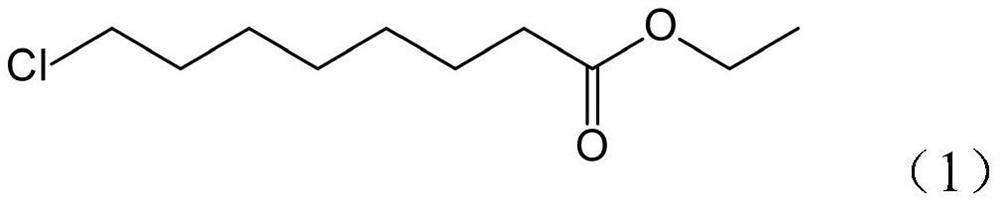

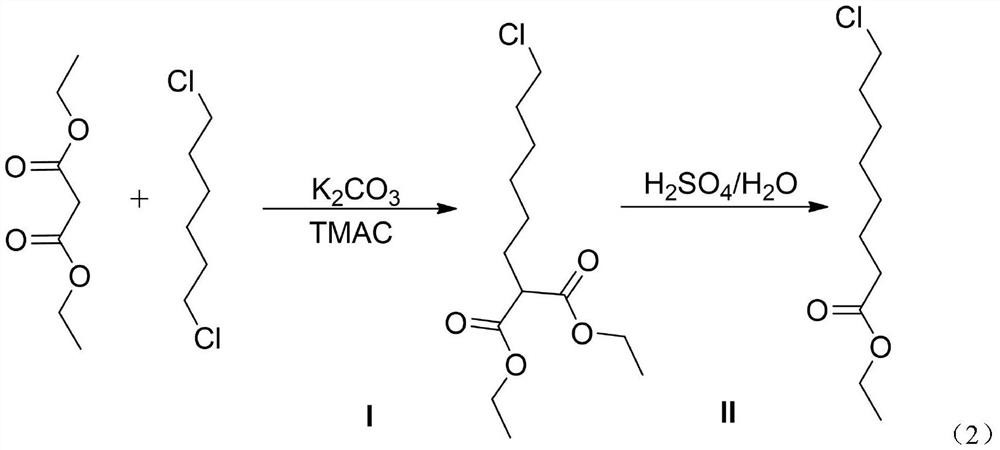

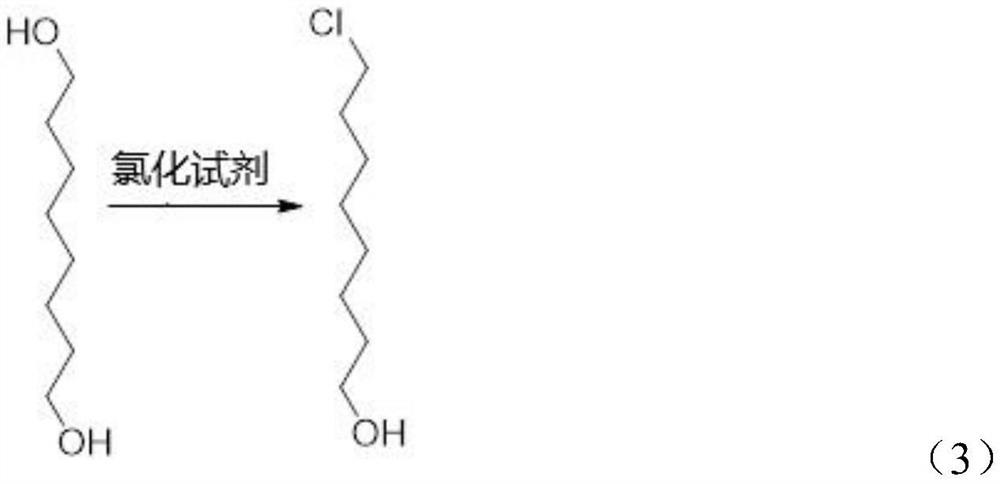

Synthesis method of 8-chloro ethyl caprylate

PendingCN112409175ASimple processLow costOrganic compound preparationCarboxylic acid esters preparationAromatic solventPtru catalyst

The invention provides a synthesis method of 8-chloro ethyl caprylate. The synthesis method comprises the following steps: S1, carrying out chlorination reaction on 1, 8-octanediol and a chlorinationreagent in an aromatic solvent to obtain 8-chloro-1-octyl alcohol; s2, carrying out oxidation reaction on the 8-chloro-1-octyl alcohol and an oxidizing agent to obtain 8-chloro caprylic acid; and S3,carrying out esterification reaction on the 8-chloro caprylic acid and ethanol under the action of a catalyst to generate the 8-chloro ethyl caprylate. According to the synthesis method of the 8-chloro ethyl caprylate, a high-purity product can be obtained, and the method is simple, convenient, easy to treat, simple in process, capable of overcoming the defects in the prior art and suitable for achieving industrial production. According to the synthesis method of the 8-chloro ethyl caprylate, the high-purity product can be obtained, and the method is simple, convenient, easy to treat, simple in process, few in side reaction and suitable for industrial production.

Owner:安徽昊帆生物有限公司

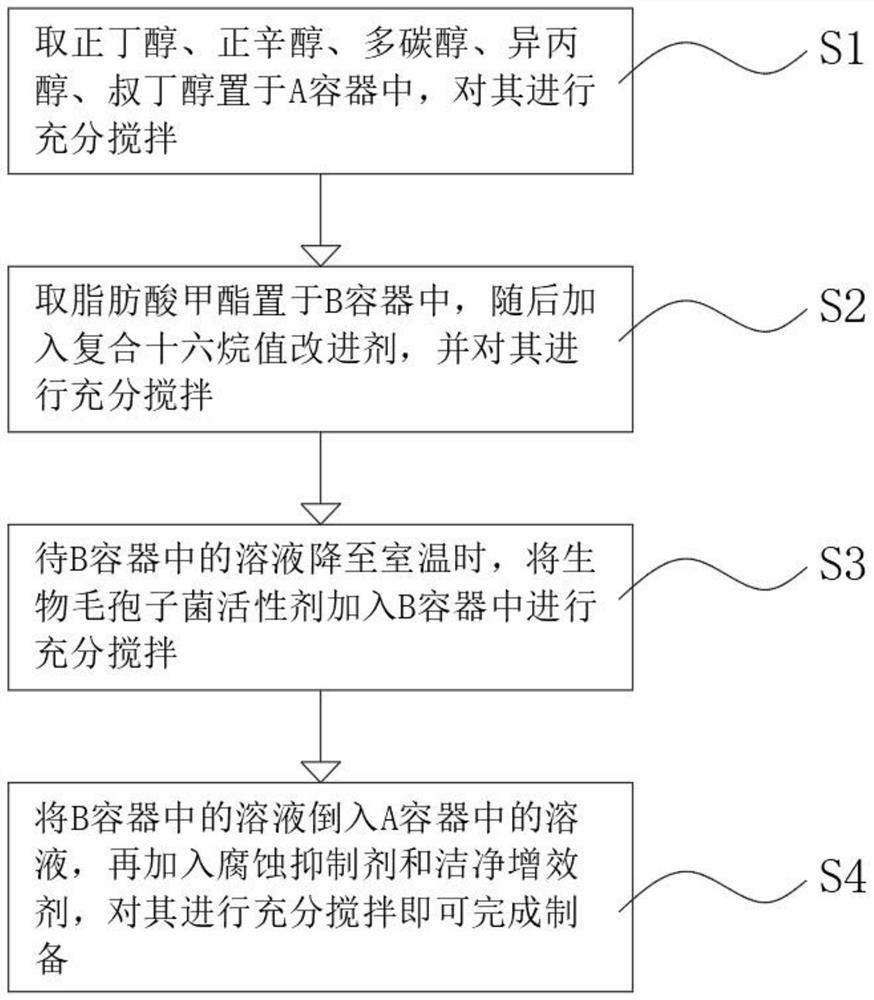

Environment-friendly and energy-saving diesel alcohol-based biofuel additive

InactiveCN113621414APlay a stabilizing roleGood explosion resistanceLiquid carbonaceous fuelsFuel additivesActive agentBiofuel

The invention relates to an environment-friendly and energy-saving diesel oil alcohol-based biofuel additive. Theenvironment-friendly and energy-saving diesel oil alcohol-based biofuel additive is prepared from raw materials in percentage as follows: 1%-3% of n-butyl alcohol, 2%-4% of n-octyl alcohol, 5%-15% of multi-carbon alcohol, 1%-3% of isopropanol, 2%-4% of tertiary butanol, 15%-25% of fatty acid methyl ester, 4%-6% of a composite cetane number improver, 5%-15% of a composite universal cosolvent and 15%-25% of a composite biological aid. The composite cetane number improver is composed of isoamyl nitrate and isooctyl nitrate in a ratio of 2: 3, the diesel oil alcohol-based biofuel additive can improve the cold start characteristic and acceleration performance of gasoline through mixing of various raw materials, is beneficial to combustion supporting and sufficient combustion of diesel oil, and can reduce the oil consumption of the diesel oil. And the content of harmful substances in exhausted tail gas is reduced, the environment is further protected, and by adding fatty acid methyl ester, a biological hairy spore bacterium active agent and other related biofuels, more energy is saved, and the environment is better protected.

Owner:安徽醇生新能源科技有限公司

High temperature resistant high-performance engineering plastics and preparation method thereof

InactiveCN109161158AImprove high temperature resistanceHighlight substantivePolytetramethylene terephthalateCardboard

The invention discloses high temperature resistant high-performance engineering plastics. The engineering plastics comprise the following components in parts by weight: 15-25 parts of phenolic resin,15-25 parts of ABS, 10-15 parts of polybutylene terephthalate, 0.1-1.5 parts of an antioxidant, 0.3-1.5 parts of a lubricant, 1-9 parts of a toughening agent, 0.1-1 part of fillings, 0.2-1 part of Al2O3, 0.5-1 part of SiO2, an auxiliary agent and a solvent, wherein the auxiliary agent comprises 0.2-1.5 parts of a nucleator, 0.2-3 parts of a fire retardant and 0.2-2 parts of a dispersing agent, andthe solvent comprises 0.5-2 parts of poly ethanol and 0.1-1 part of n-octyl alcohol. The high temperature resistant high-performance engineering plastics disclosed by the invention are good in high temperature resistant effects, and can be effectively applied to high temperature field; besides, cardboard respects disclosed by the invention are simple but not tedious to operate; the high temperature resistant properties of the prepared engineering plastics are better.

Owner:NANJING OUNAYI ORGANIC PHOTOELECTRICITY CO LTD

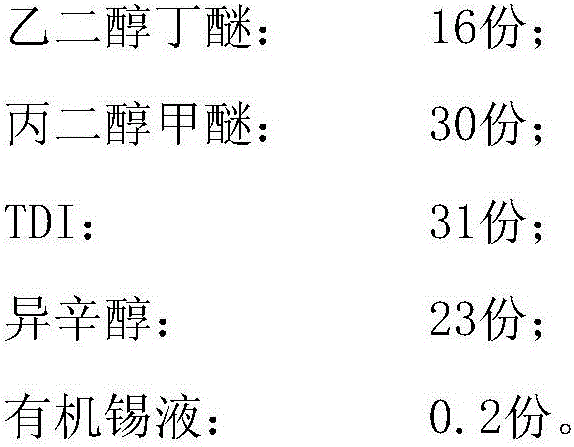

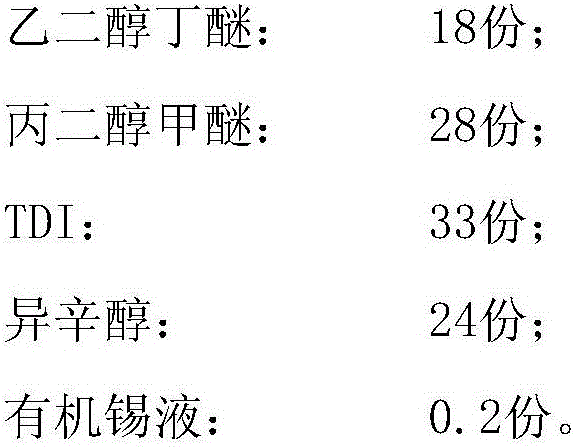

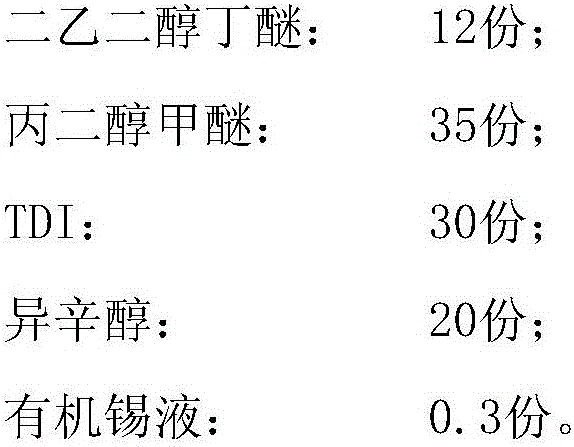

Cross-linking agent for cathode electrophoretic paint and production process thereof

InactiveCN106009871AIncreased corrosion resistanceSimple processAnti-corrosive paintsPaints for electrolytic applicationsCross-linkAlcohol

The invention relates to a cross-linking agent for cathode electrophoretic paint and a production process thereof. The cross-linking agent is prepared from the following ingredient raw materials in parts by weight: 40 to 53 parts of composite alcohol ether, 24 to 33 parts of TDI (toluene diisocynate), 19 to 24 parts of isooctanol and 0.2 to 0.3 part of organic tin liquor. The cross-linking agent has the advantages that the process is simple, the maneuverability is high, and the like. In the preparation process of the cross-linking agent, the volatilization cannot easily occur; safety and environment protection are realized. The paint produced by using the cross-linking agent has the advantages that the paint film thickness is greater, and the anti-corrosion performance is greatly improved.

Owner:WEIFANG HELI WATER BASED PAINT MAKING CO LTD

High-temperature-resistant power protection pipe

InactiveCN105001550AHigh mechanical strengthIncreased mechanical toughnessSodium stearatePolyvinyl chloride

The invention discloses a high-temperature-resistant power protection pipe which is characterized by being prepared from the following raw materials in parts by weight: 100-130 parts of polyvinyl chloride, 2-4 parts of magnesium hydroxide, 0.1-0.4 part of stearic acid, 6-10 parts of calcium carbonate, 0.2-0.5 part of sodium lignosulfonate, 1-2 parts of nano antimony trioxide, 0.5-1 part of sodium oleate, 0.4-1 part of a silane coupling agent kh550, 1-2 parts of sodium stearate, 2-3 parts of chlorinated polyethylene, 0.5-1 part of epoxidized soybean oil, 0.3-0.7 part of zinc butyl octyl alcohol dithiophosphate, 1-2 parts of oxidized polyethlene wax, and a proper amount of water. The high-temperature-resistant power protection pipe has the advantages of excellent high-temperature resistance, good corrosion resistance, good aging resistance, good flame retardancy, high mechanical strength and high toughness, and the service life of the high-temperature-resistant power protection pipe is prolonged.

Owner:安徽盛华管业有限公司

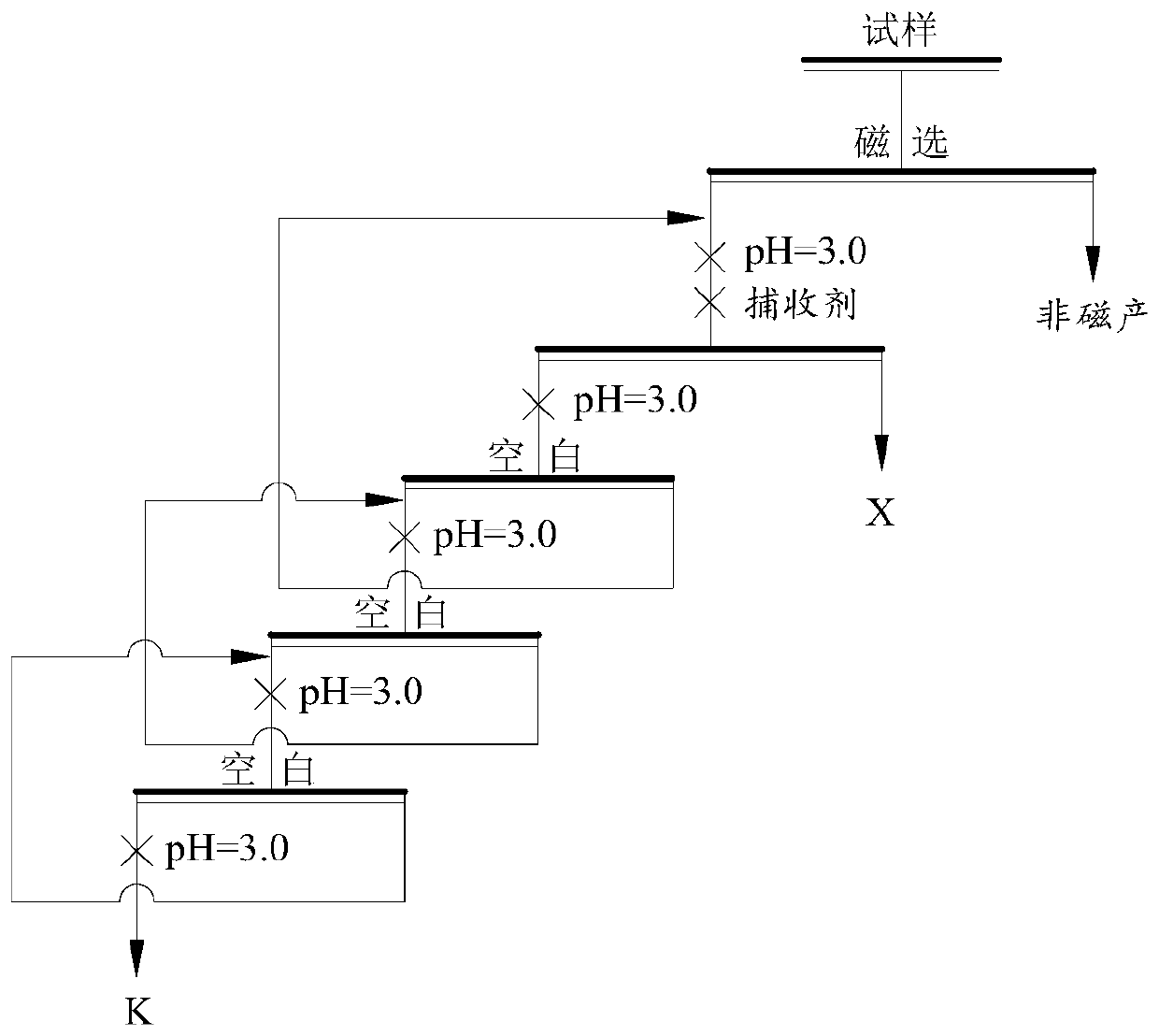

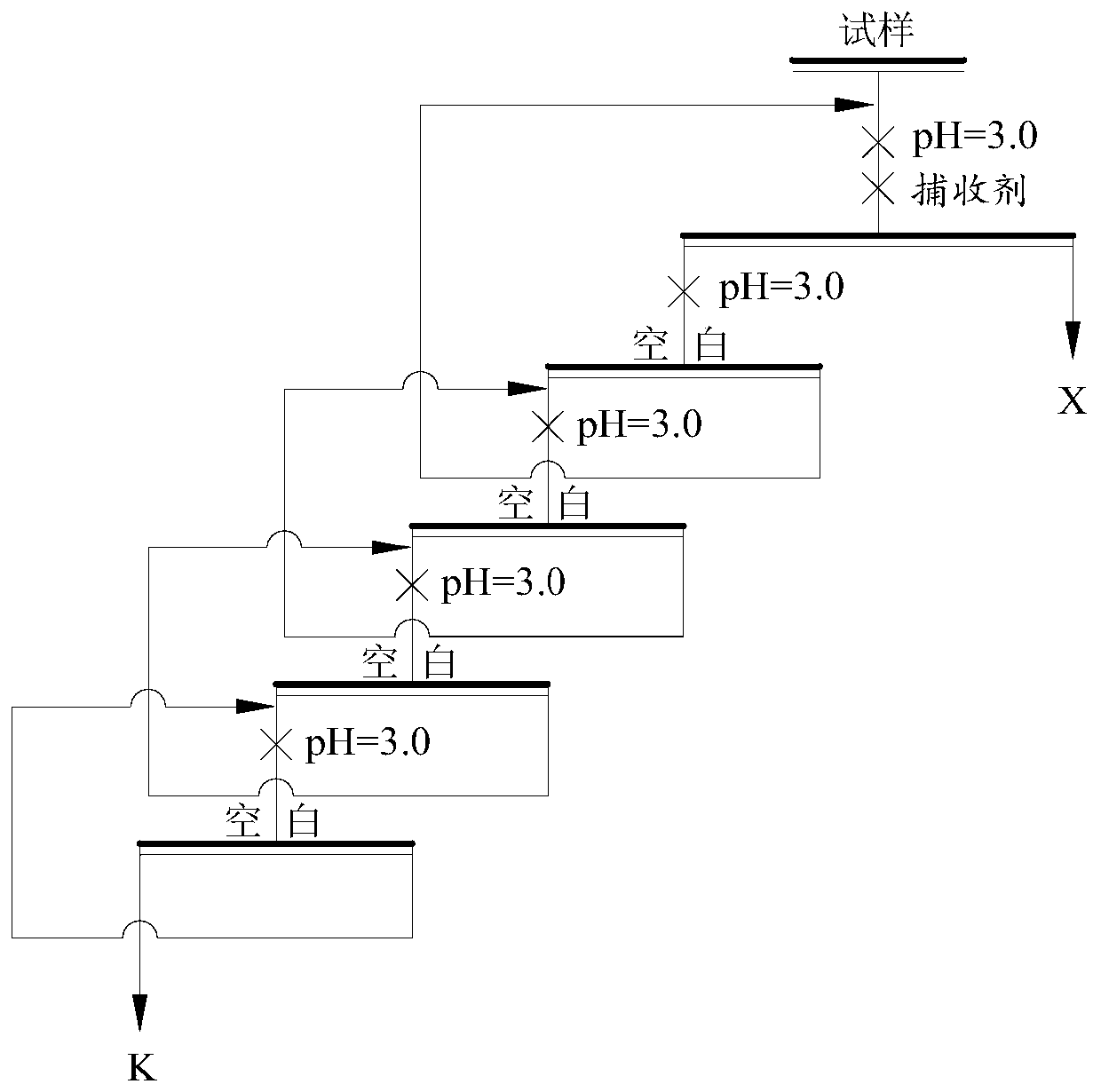

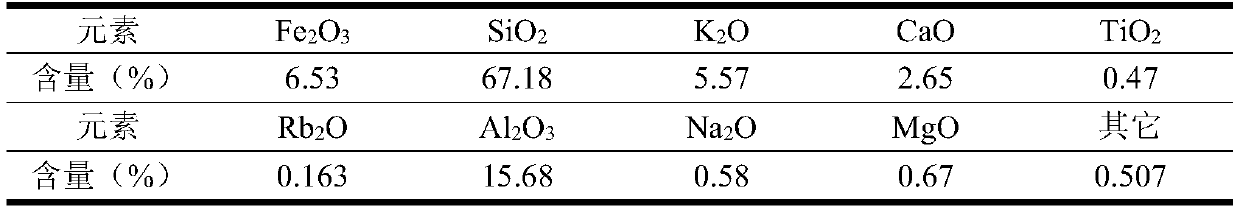

Combined collecting agent suitable for flotation of rubidium-containing fine-grained mica and application of combined collecting agent

The invention discloses a combined collecting agent suitable for flotation of rubidium-containing fine-grained mica. The combined collecting agent comprises dodecylamine and sec-octyl alcohol in a weight ratio of 1: (1-2). In addition, the invention further discloses an application of the combined collecting agent suitable for flotation of the rubidium-containing fine-grained mica. The combined collecting agent is applied to the following ore samples: tuff-type rubidium-containing biotite ore and skarn-type rubidium-containing biotite ore, the particle size is smaller than or equal to 0.032 mm, the combined collecting agent is adopted for flotation, and the using amount of the combined collecting agent is 250-280 g / t according to the ore samples. The combined collecting agent has the advantages of being low in foam viscosity, good in fluidity, easy to prepare and the like, entrainment of fine-grain gangue in concentrate foam can be effectively reduced, and therefore the rubidium gradeof rubidium concentrate is improved, the cost of beneficiation reagents is reduced, and industrial application and development of rubidium resources are facilitated.

Owner:GUANGDONG INST OF MINERAL APPL

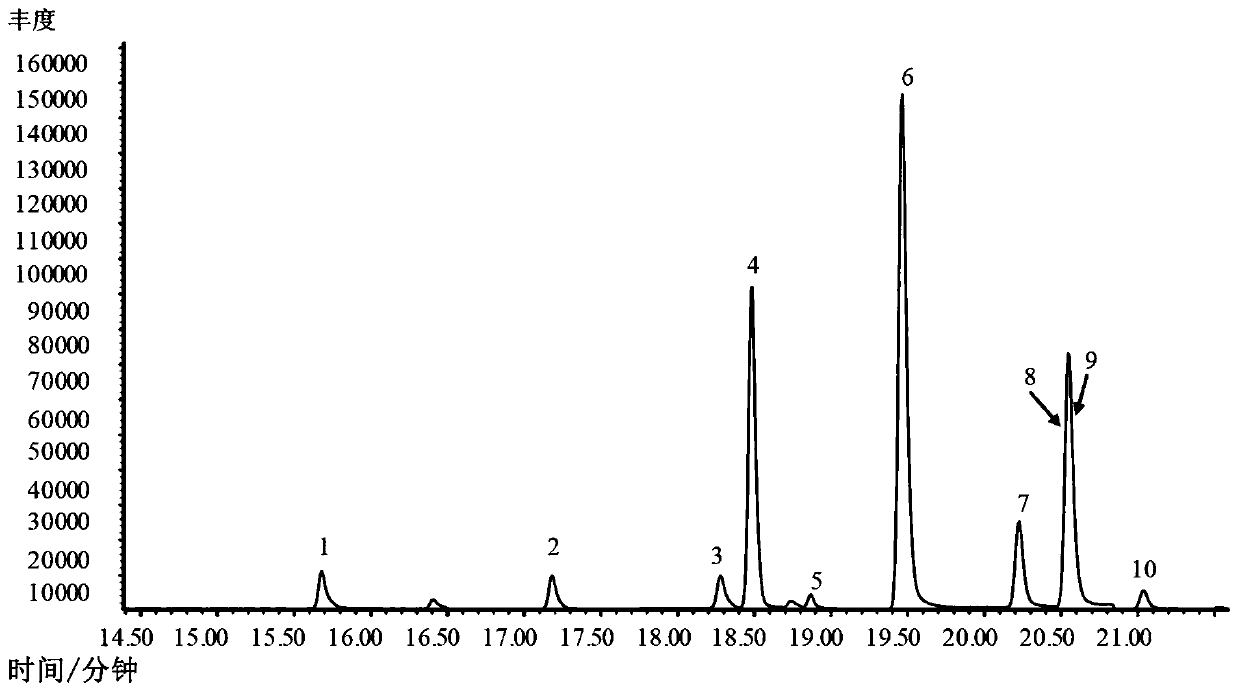

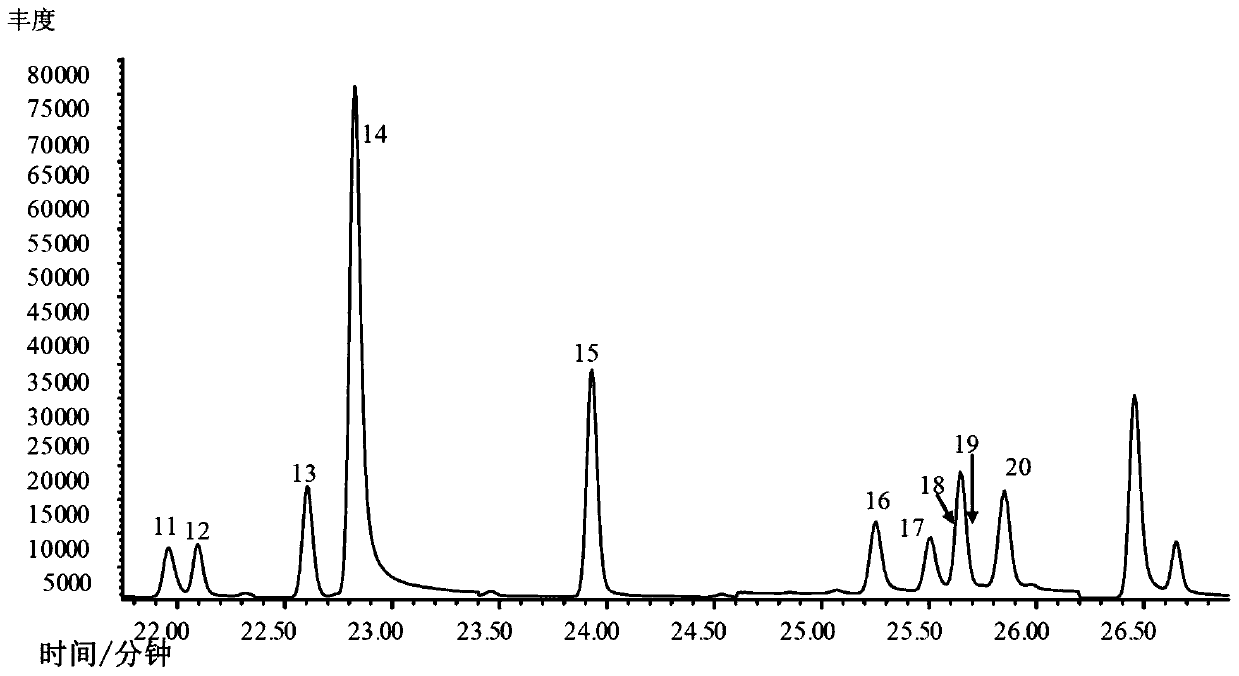

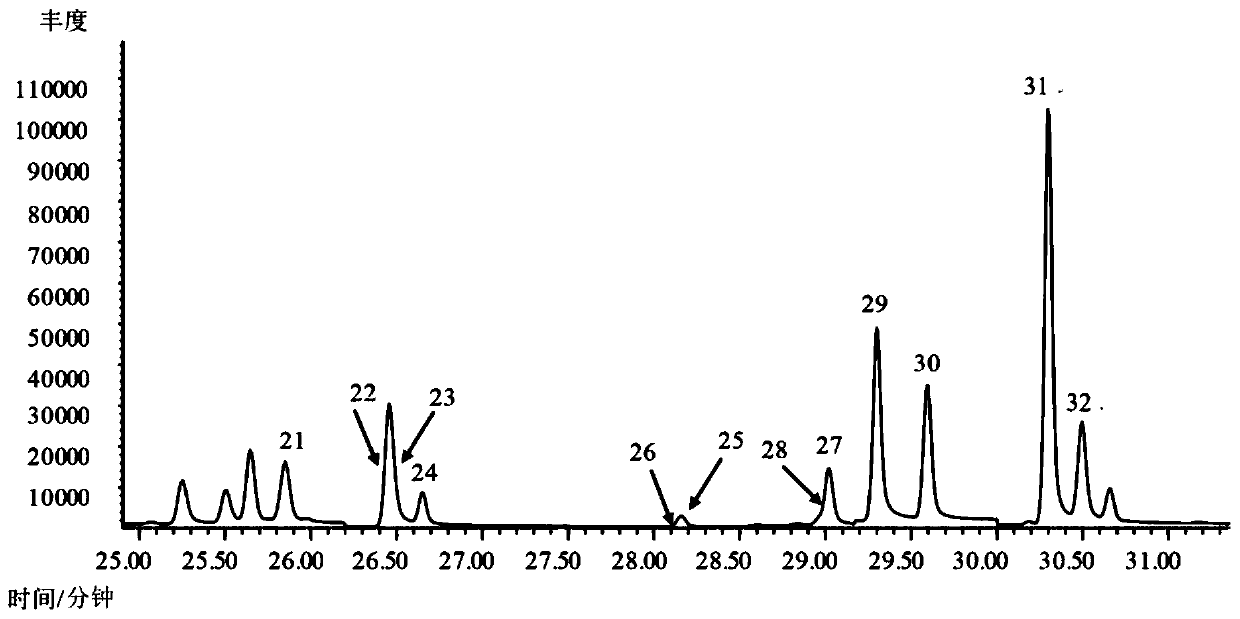

Method for determining floral components in mainstream smoke of cigarettes

The invention belongs to the technical field of smoke component detection, and particularly relates to a method for determining floral components in mainstream smoke of cigarettes. The method comprises the following steps: extracting collected cigarette mainstream smoke particulate matters by using acetone to obtain an extracting solution; analyzing the extracting solution by adopting gas chromatography-mass spectrometry, and detecting the content of the floral components by adopting an internal standard method, wherein an internal standard substance used in the internal standard method is storax propionate, and the floral component is composed of heptanol, sec-octyl alcohol, p-toluenemethyl ether, 2-ethylhexanol, ocimene, phenylacetaldehyde and other components with floral fragrance. Themethod disclosed by the invention can be used for simultaneously detecting the contents of the 45 floral components in the cigarette smoke, and has the advantages of rapid detection, high sensitivity,good selectivity and high accuracy.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com