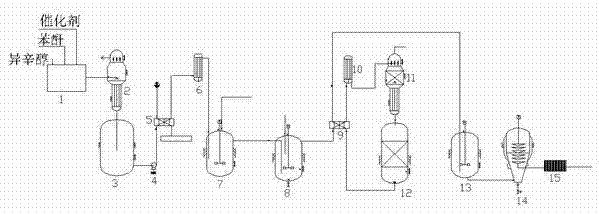

A kind of dop continuous production process and used equipment

A production process and equipment technology, applied in the field of production process and equipment used, can solve the problems of high energy consumption and limited production capacity of a single set, and achieve the effects of low energy consumption, reduced energy consumption, and increased production output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

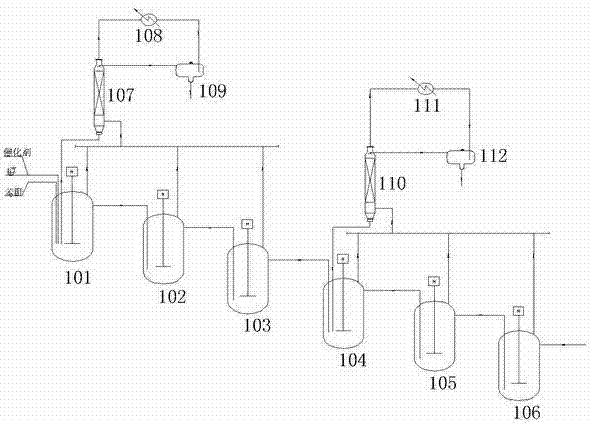

Embodiment 1

[0030] Example 1: Heating isooctyl alcohol to about 180°C, with 10 m 3 / h flow rate into the first esterification tank 101, after adding 5m3, start the agitator. Open the steam control valve, the first esterification kettle 101 isooctyl alcohol is slowly warmed up to 184 ℃, open the steam control valve of the second esterification kettle 102 to the sixth esterification kettle 106 simultaneously, control the temperature of these three reactors at Above 184°C, to avoid condensation of alcohol vapor in it, after adding octanol to the first esterification kettle 101 for 1 hour, determine the feeding ratio and input phthalic anhydride (4T / h) and catalyst 4.3Kg / h (catalyst pump stroke: 3.0) to start the catalyst Feed: control the temperature of the first esterification tank 101 to carry out the esterification reaction at 190°C, the alcohol and water vapor distilled from the top of the first esterification tower 107 are cooled by the first cooler 108, and the condensed alcohol-water ...

Embodiment 2

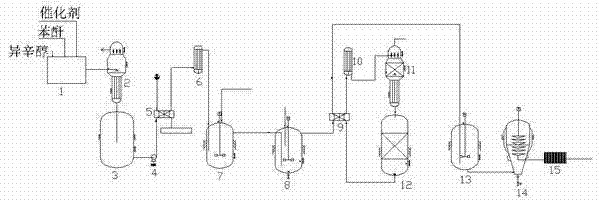

[0031] Embodiment 2: Dealcoholization process: a. Utilize the residual heat of reaction materials, and separate most of excess alcohol through decompression flash evaporation; b. Reduce the emulsification factor of neutralization and washing, which is beneficial to the phase separation of neutralization and washing; c. Recover Part of octanol is used for esterification.

[0032] Put the crude ester of the esterification product obtained in Example 1 into the alcohol-ester heat exchanger 5 through the crude ester pump 4, and add another pipeline through low-temperature alcohol to perform heat exchange, initially cool the temperature of the crude ester, and then enter the The temperature in the ester cooler 6 is further lowered to about 95°C, and it is added to the dealcoholization tower. Under the condition of an absolute pressure of 5KPa, the temperature at the bottom of the tower is set at 190°C, and the temperature at the top of the tower is set at 170°C. Excess alcohol is ev...

Embodiment 3

[0033] Example 3: Neutralization and washing process: Tasks of this section: a. Use the waste heat of the reaction materials to separate most of the excess alcohol through decompression flash evaporation; b. Reduce the emulsification factor of neutralization and washing, which is beneficial to neutralization and washing phase separation; c. reclaim part of octanol for esterification.

[0034] In Example 2, the tower bottoms that have been dealcoholized and cooled to 95°C are sent to the neutralization tank 7, and the dilute solution diluted to 0.4% by 30% NaOH is added, and the temperature is raised to 90°C before being added to the neutralization tank , Stirring and neutralization reaction at a temperature of 95 ° C, until the acid value in the ester phase ≤ O. 05mgKOH / g, the pH value of the water phase is 11-12, after the reaction is completed, the ester phase enters the water washing kettle 8, and the water at 95°C whose mass is 20-30% of the ester content is added for wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com