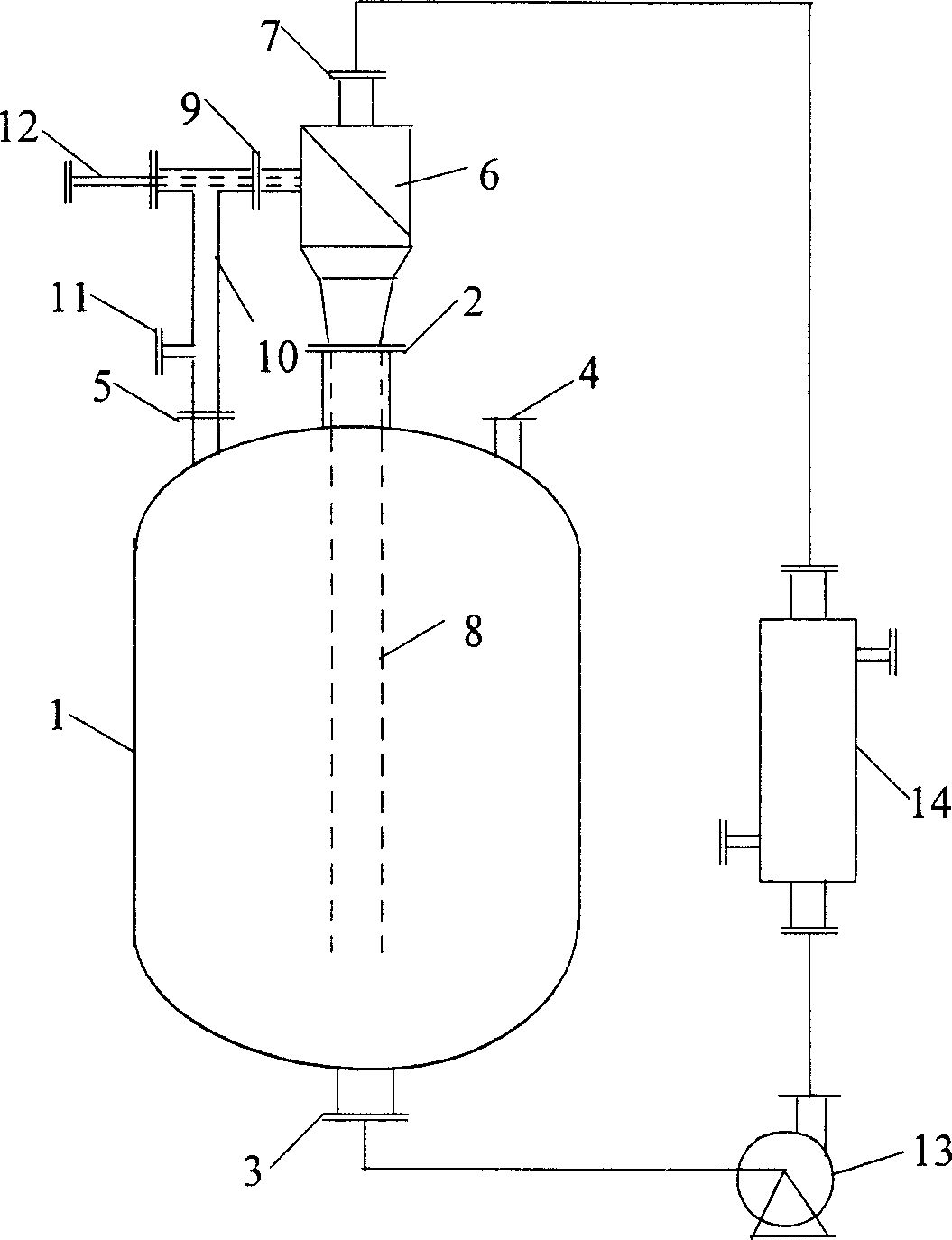

Process for preparing n-hexylic acid by oxidation of sec- octyl alcohol with nitric acid and its special device

A nitric acid oxidation and sec-octanol technology, which is applied in the oxidation preparation of carboxylic acid, organic chemistry, etc., can solve the problems of waste of resources, complicated operation, uneven gas-liquid mixing, etc., to reduce NO content, reduce air pollution, and reduce workload small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1600Kg secondary octanol (weight content≤82%) and 2.0Kg V 2 o 5 It is fed into the reactor through the feeding port on the upper part of the jet-down reactor reactor 1. Start the non-leakage pump 13 to mix and circulate the materials and heat them. When the temperature > 95°C, open the nitric acid feed pipe 12 and the air inlet 11, nitric acid, air, 2-octanol, catalyzer and the nitric oxide emitted in the reaction sucked through the liquid jet vacuum pump suction port 9 via the reaction mixture outlet 5 Gases and the like are uniformly mixed in the jet vacuum pump 6. Control nitric acid addition speed, make reaction temperature2 )2.1312mg / m 3 . After the addition of nitric acid, the temperature was raised to 120°C, and the temperature was kept at full reflux for 3 hours to complete the oxidation. After the heat preservation is over, the natural cooling is allowed to stand for stratification, and the acid-containing water layer (recycled for diluting nitric acid) is...

Embodiment 2

[0016] Embodiment 2, in the present embodiment, add the secondary octanol 1500Kg after absorbing nitric oxide, the front and rear cuts in the rectification are 100Kg altogether, V 2 o 5 2.0Kg, and dilute to the nitric acid 3850Kg of weight percentage concentration 45% with separating spent acid, equipment used and concrete operation are with embodiment 1. After purification, 1880Kg of oxidation solution is obtained, the weight content of hexanoic acid is ≥63%, the weight content of acetic acid is ≥27%, and the content of nitrogen oxides in the exhaust tail gas (converted into NO 2 )≤3.5mg / m 3 .

Embodiment 3

[0017] Embodiment 3, in the present embodiment, add the secondary octanol 1500Kg after absorbing nitric oxide, the front and rear cuts in the rectification are 100Kg altogether, V 2 o 5 2.0Kg, and 3850Kg of nitric acid diluted to weight percentage concentration 45% with separating waste acid, used equipment and concrete operation are as embodiment 1. After purification, 1883Kg of oxidation solution is obtained, the weight content of hexanoic acid is ≥63%, the weight content of acetic acid is ≥29%, and the content of nitrogen oxides in the exhaust tail gas (converted into NO 2 )≤3.5mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com