Assembled pier transporting and erecting all-in-one machine and assembled pier transporting and erecting method based on same

An assembled and all-in-one machine technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of low safety and reliability of large-scale truck crane operations, high comprehensive cost, and difficulty in implementation, and achieves improved transportation. Operational efficiency, safety and reliability, environmental adaptability, and construction cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

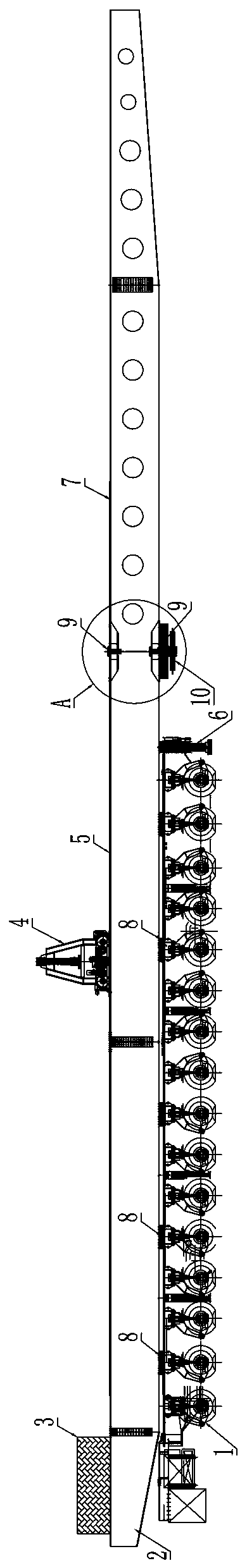

[0054] Such as figure 1 Shown is an assembled bridge pier transport frame integrated machine, which includes a pier section transport vehicle 1, a main girder 2 and a pier section hoisting crane 4.

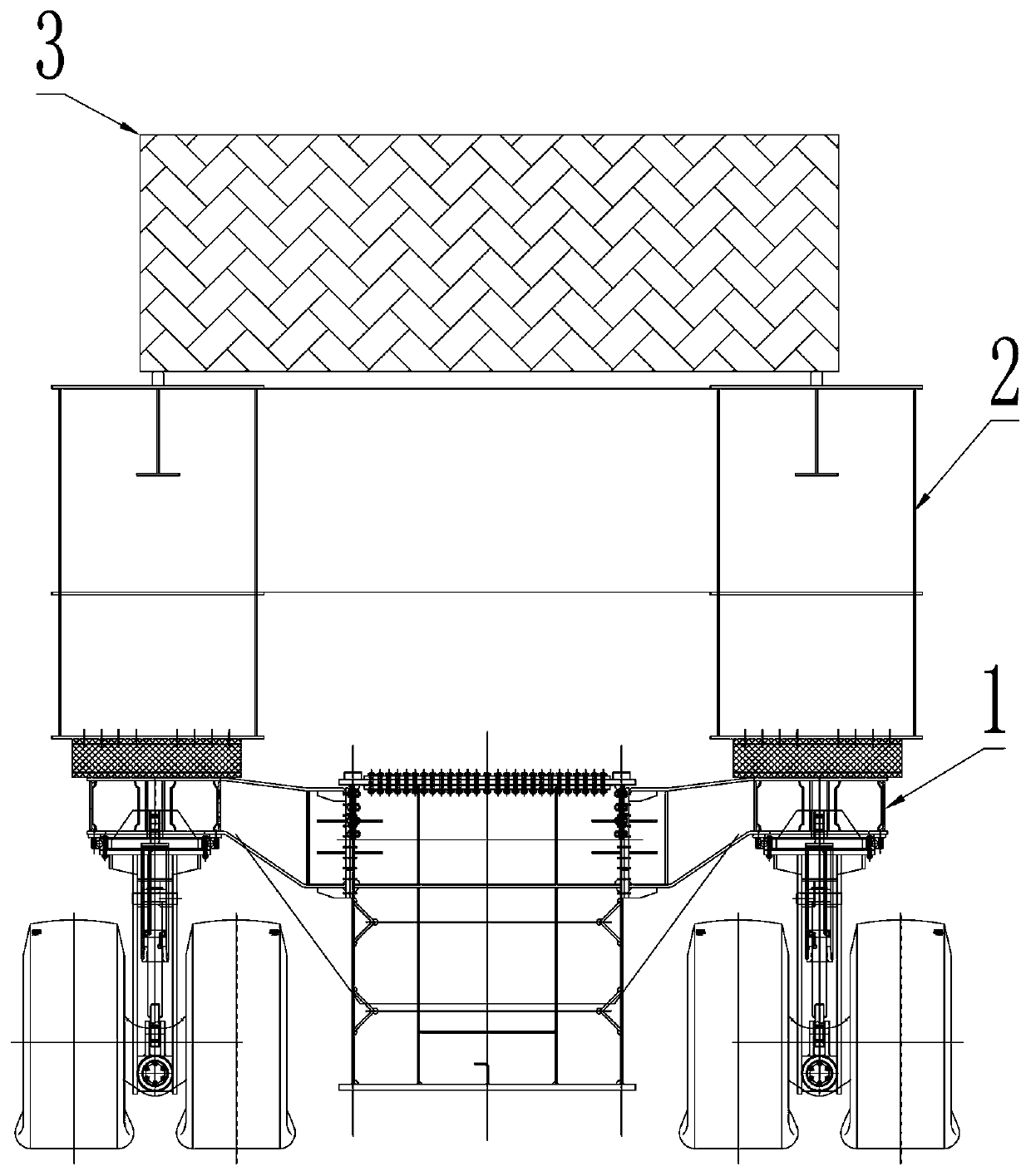

[0055] The pier transport vehicle 1 is a multi-axle tire-type hydraulic transport flat car; it can be designed and manufactured separately, or it can be replaced by a beam transport vehicle for transporting high-speed rail box girders existing in the current construction unit; the main beam 2 is Two and fixedly arranged on the pier section transport vehicle 1 in parallel, the front end of the main girder 2 extends out of the pier section transport vehicle 1 and hangs on the pier section transport vehicle 1, leaving a space between the two main girders 2 There is space for placing pier components to be assembled; the pier section lifting crane 4 can move longitudinally along the track on the top surface of the main girder 2, and the pier section lifting crane 4 is used for lifting ...

Embodiment 2

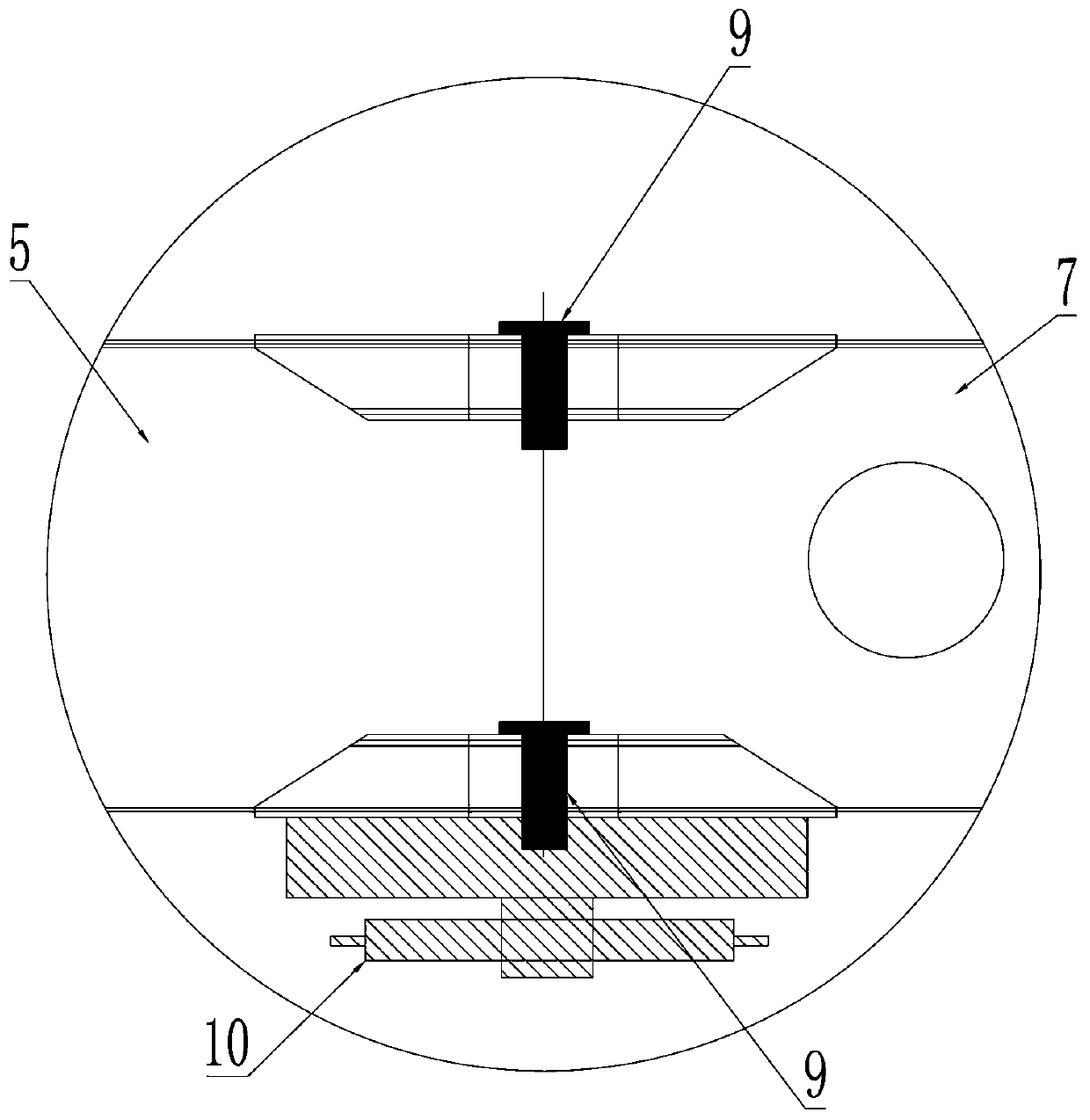

[0058] Such as Figure 1 to Figure 11 As shown, as a preferred embodiment of the assembled bridge pier transport frame integrated machine, on the basis of Example 1, the main girder 2 includes two fixed main girder sections 5 fixedly installed on the top surface of the pier section transport vehicle 1 and the foldable front cantilever main beam section 7 hinged at the front end of the fixed main beam section 5; The piers transport vehicle 1 is extended, and a main beam support cylinder 6 for supporting with the box girder is arranged at the bottom of the extended position. The tail of the main beam 2 is provided with a balance weight 3 for pressing down the pier transport vehicle 1 .

[0059] Such as figure 1 and figure 2 As shown, the fixed main beam section 5 and the foldable front cantilever main beam section 7 are hinged by a shear pin 9, and the fixed main beam section 5 and the foldable front cantilever main beam section 7 pass through The swing cylinder mechanism 1...

Embodiment 3

[0067] A method for transporting frame of assembled bridge pier based on the integrated machine for transporting frame of assembled bridge pier described in embodiment 1, it comprises the following steps:

[0068] (1) According to the installation sequence of each pier assembly of the assembled pier, each pier assembly is placed on the top surface of the pier section transport vehicle 1 from front to back and fixed; the pier assembly includes a plurality of pier sections 101 and A pier cap 102 .

[0069] (2) The assembled bridge pier transport frame integrated machine travels to the bridge head, extends the main girder support oil cylinder 6 to support the beam end of the box girder that has been erected, and the pier joint hoisting crane 4 lifts the pier joints 101 of the assembled pier in turn , move forward, fall and install to form the pier body of the assembled pier.

[0070] (3) After all the pier body segments are installed, the pier joint hoisting crane 4 lifts, moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com