Method for mounting main bridge variable cross-section continuous steel truss girder by using cable crane

A technology of cable crane and steel truss girder, which is applied in the direction of erecting/assembling bridges, bridges, bridge forms, etc., which can solve the difficulty of horizontal and vertical transportation of components to the construction work surface, and the lack of rear balance section assembly site for bridges in mountainous areas. Problems such as the force of the large pier-beam joint are achieved to facilitate vertical and horizontal transportation, increase the construction work surface, and speed up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

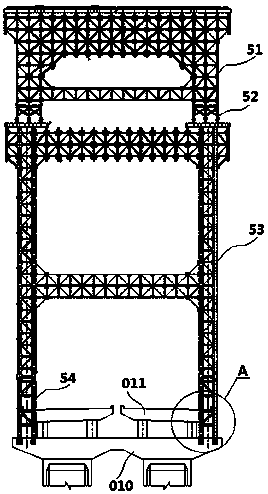

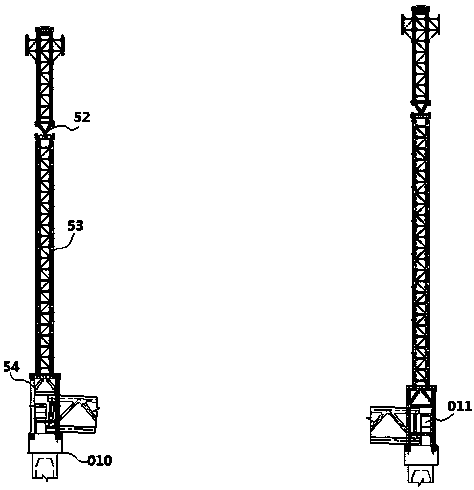

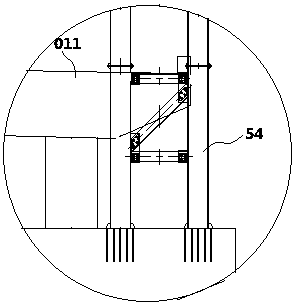

[0070] Such as figure 1 with figure 2 As shown, a cable crane in this embodiment includes a main anchor 01, a main load-bearing cable 02, a wind cable, a lifting trolley, a cable saddle and a tower, and the tower includes a left bank tower 05 and a right bank tower 07; Among them, there are two main anchors 01 on the left and right banks, and the two main anchors 01 on each bank are symmetrically arranged on both sides of the centerline of the main bridge of the bridge, and respectively correspond to the layout of the left and right bridges. The two main anchors 01 on each bank are respectively The centerline of the left and right bridges is arranged, and each main anchorage 01 is 8.5m away from the longitudinal axis of the cable crane (the centerline of the main bridge of the bridge), and the main anchorages 01 on both banks are anchored by reinforced concrete pile cap structure.

[0071] It should be noted that the bridge in this embodiment includes a curved section and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com