Method and device for identifying laser damage of optical thin film based on polarization parameters

A technology of laser damage and optical thin film, which is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as misjudgment, and achieve wide application prospects, high discrimination accuracy, and a wide range of types Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments. These examples are for illustrating the present invention and do not limit the scope of the present invention.

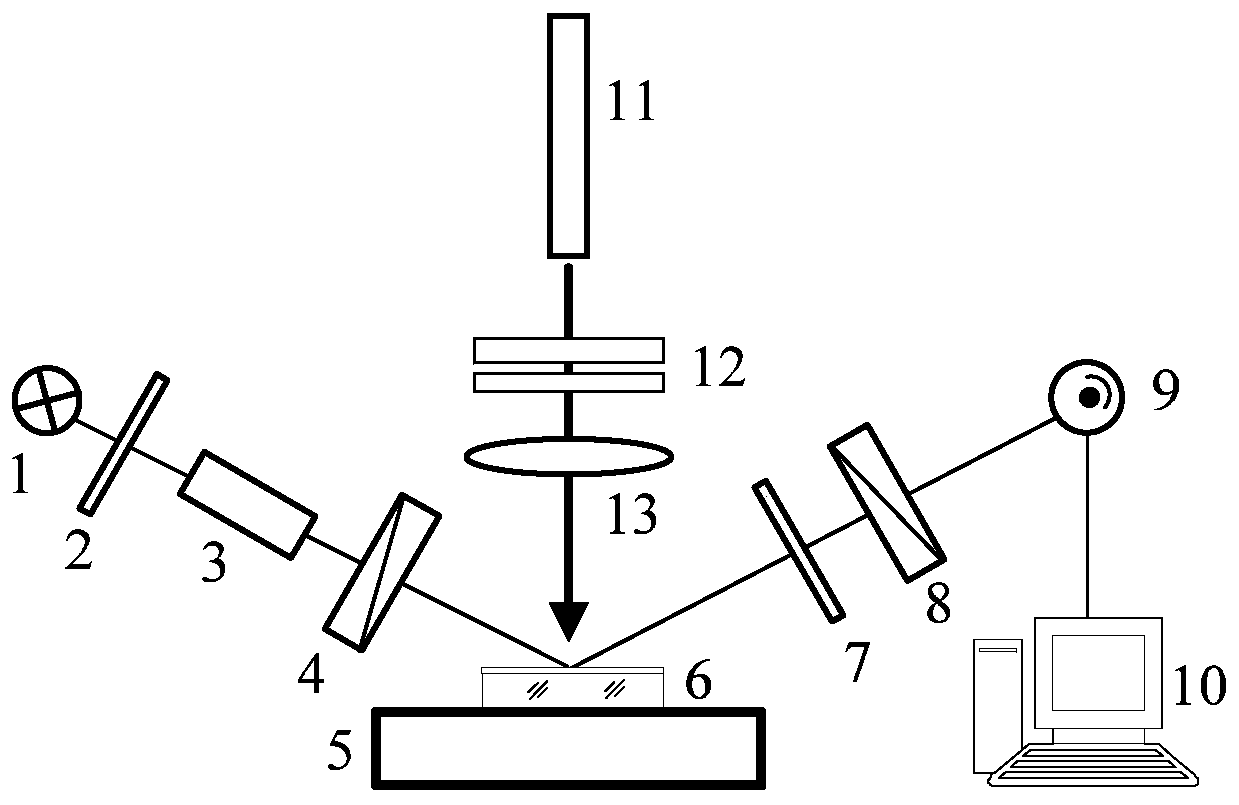

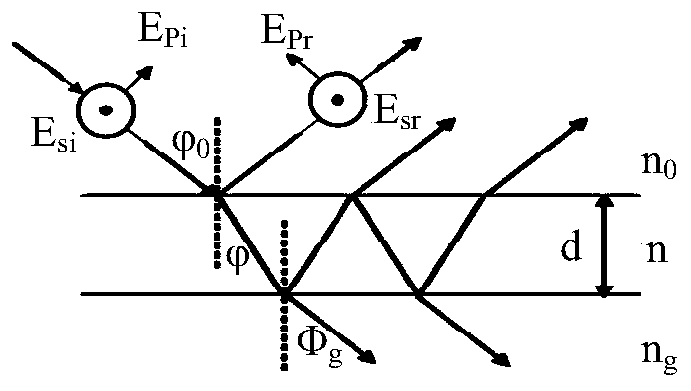

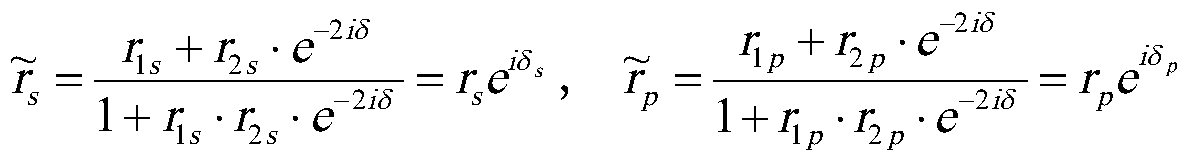

[0023] The present invention is a laser damage discrimination device for identifying optical thin films based on polarization parameters, see figure 1 A light source 1, a narrow-band filter 2 capable of monochromatic light output, a collimator 3 for collimation, and a polarizer 4 for generating linearly polarized light are sequentially arranged on one side of the incident light path of the two-dimensional workbench. Wherein, the light source 1 is an incandescent light source, and the emission spectrum is 400-700nm. Filter 2 is a narrow bandpass filter with a wavelength of 650±1nm and a half width of 5nm. The polarization azimuth angle of the polarizer is 45°, and the incident angle of the linearly polarized light generated by the polarizer 4 on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com