Automatic deviation rectification control method for magnetic guidance AGV

A control method and automatic deviation correction technology, applied in the field of robots, can solve the problems of unstable railway transportation system, unable to realize the inspection and maintenance of indoor equipment in traction substations in time, and reduce the labor participation rate, eliminate the deviation angle error, and make it easy to use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In this embodiment, an automatic deviation correction control method of a magnetically guided AGV is carried out in the following steps:

[0088] Step 1. Obtain the pose information of the magnetically guided AGV during demagnetization;

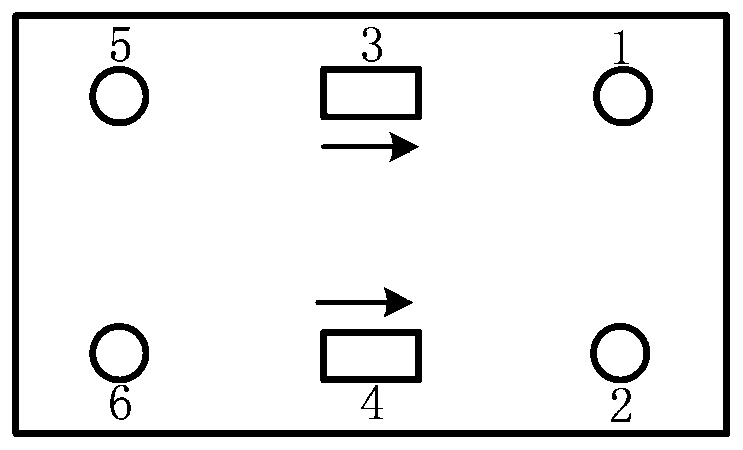

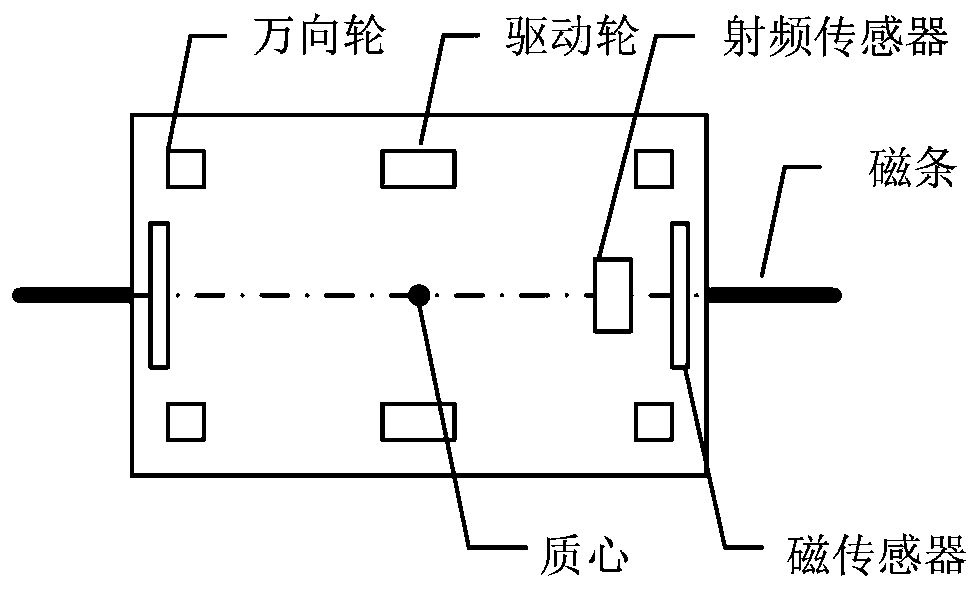

[0089] In this example, the chassis is a six-wheel differential magnetically guided AGV, with four universal wheels at the front and rear, and the middle two are driving wheels. The schematic diagram of the chassis is as follows figure 1 as shown, figure 1 Wheels 1, 2, 5, and 6 are four driven wheels, and wheels 3 and 4 are two driving wheels. The movement is flexible and can realize turning in situ.

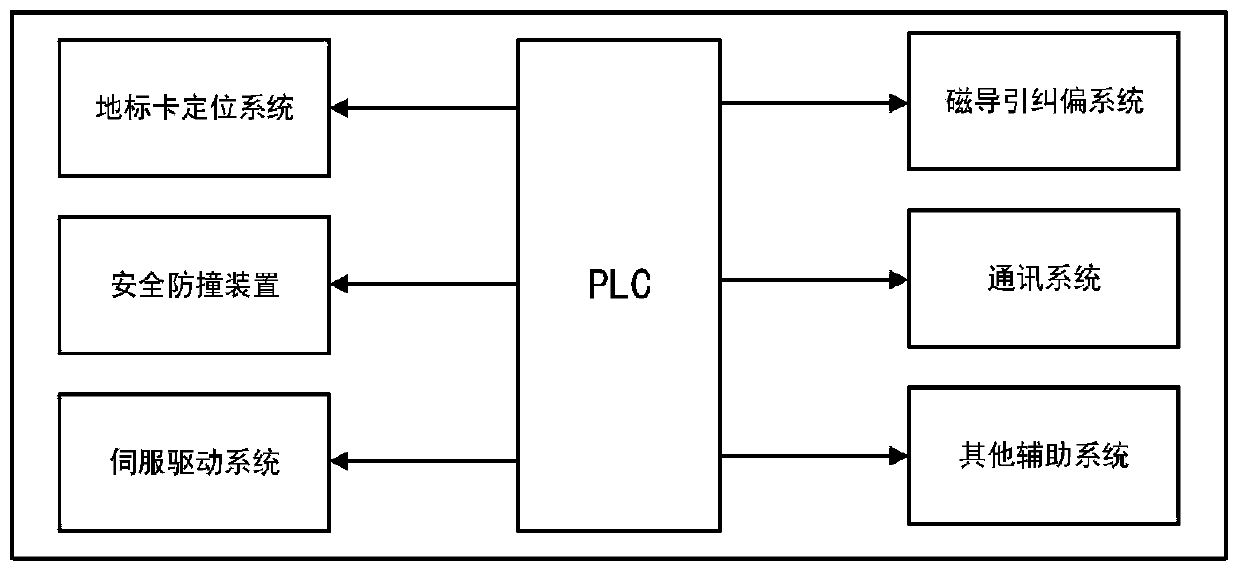

[0090] The AGV realizes functions such as deviation correction and rotation through the differential speed of the left and right wheels. This AGV is mainly composed of PLC, car body part, landmark card positioning system, magnetic guide deviation correction system, safety anti-collision device, communication system, servo drive system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com